Vacuum chuck type crawling device

A technology of vacuum suction cups and crawling devices, applied in suction cups, transportation and packaging, connecting components, etc., can solve problems such as inability to complete actions, easy to slip, etc., and achieve the effect of high flexibility and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

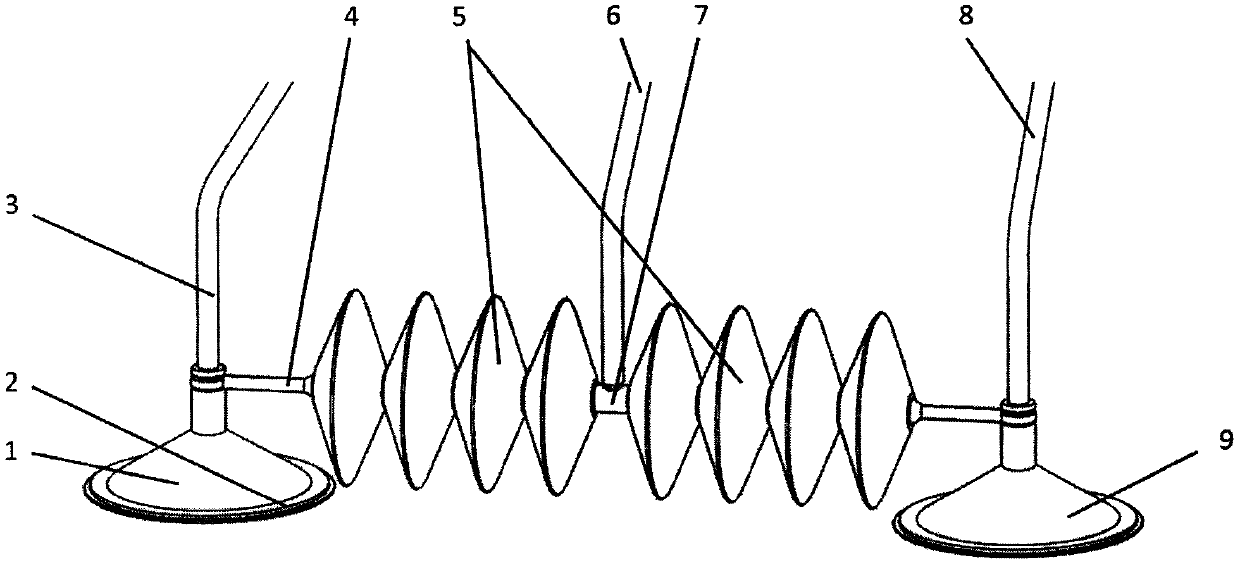

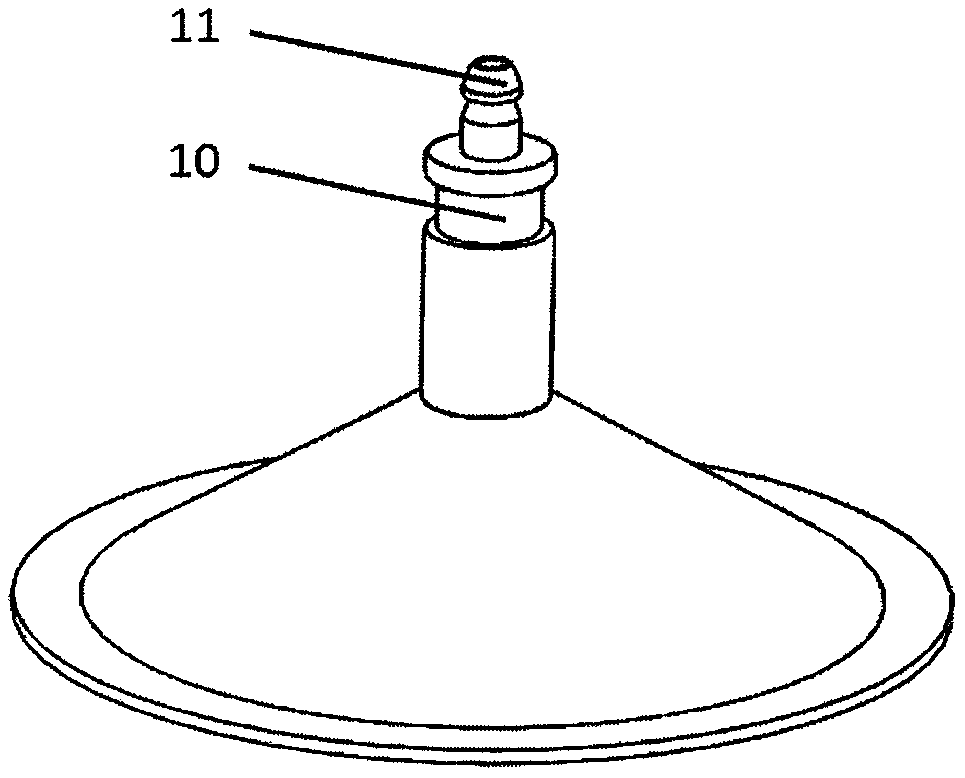

[0017] The vacuum suction cup type crawling device of the present invention is mainly composed of a rear vacuum suction cup 1, a sealing pad 2, a rear suction cup air pipe 3, a connecting rod 4, a corrugated telescopic pipe 5, an air filling pipe 6, a connecting pipe 7, a front suction cup air pipe 8, and a front vacuum pipe. Suction cup 9, suction cup neck and shoulder 10, suction cup trachea joint 11, filling and suction pipe joint 12, connecting collar 13; The air pipe joint 12 forms an internally closed cavity, the other ends of the two corrugated telescopic tubes 5 are fixed on the ends of the two connecting rods 4, and the two connecting collars 13 are respectively fixed on the other ends of the two connecting rods 4; the gasket 2 They are bonded and fixed on the bottom surfaces of the two vacuum suction cups (1, 9) respectively, the neck shoulders 10 of the two suction cups are respectively fixed on the upper parts of the two vacuum suction cups (1, 9), and the two sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com