Industrial robot based knee-joint prosthesis testing device and testing methods

A technology of industrial robots and testing devices, applied in prosthetics, artificial legs, medical science, etc., can solve problems such as difficulty in ensuring the same input of prosthetics, reducing the accuracy of test data, and inability to achieve testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

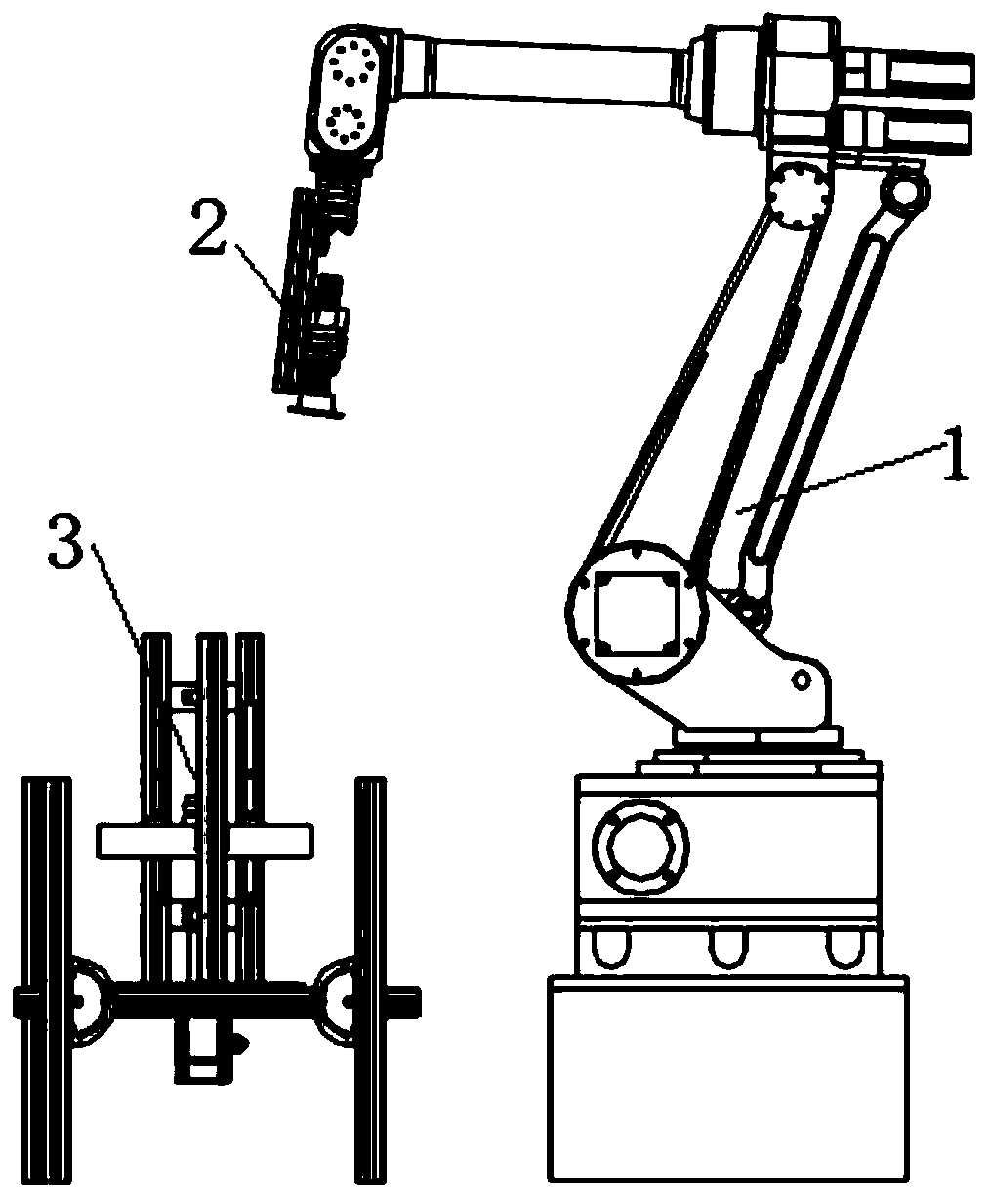

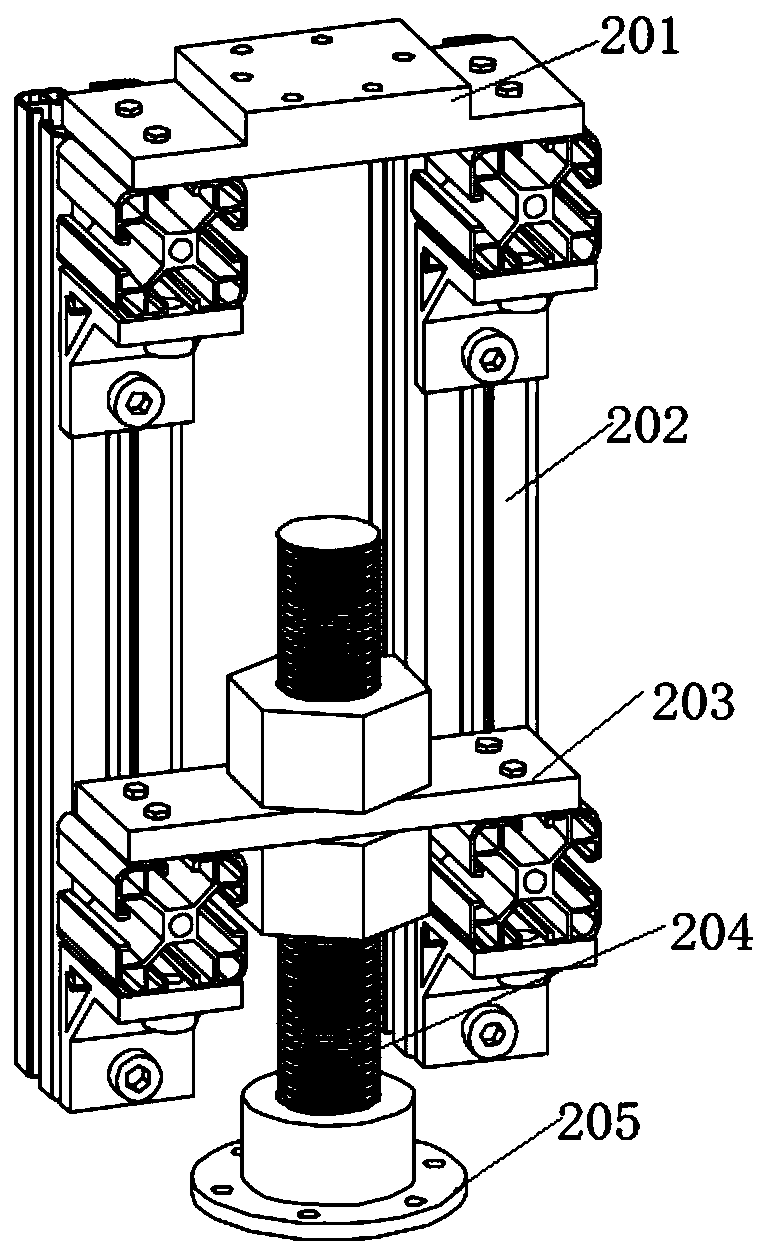

[0047] Such as figure 1 As shown, a knee prosthetic test device based on an industrial robot includes an industrial robot 1, a bionic thigh 2 and a ground reaction module 3, wherein the industrial robot 1 and the ground reaction module 3 are fixed on the ground, and the industrial robot 1 Arranged behind the ground reaction force module 3, the bionic thigh 2 is connected to the interface of the industrial robot 1;

[0048] Industrial robot 1 is a SIASUN SR120D industrial robot with six degrees of freedom. During the test, it can perform translation in two directions and drive the bionic thigh to swing. The translation of is used in the stance phase to simulate the horizontal translation of the hip joint during walking. At the same time, the rapid movement during the swing phase makes the tested prosthesis be at the starting position of the next step cycle w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com