Metal structure fatigue life calculation method based on material corrosion damage factor and weld crack damage factor

A metal structure and damage factor technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as simultaneous consideration and deviation in the collaborative damage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0084] The case selects a gate hoist at the dam crest of a power station, its main metal structure is Q345, and its yield strength is 345MPa.

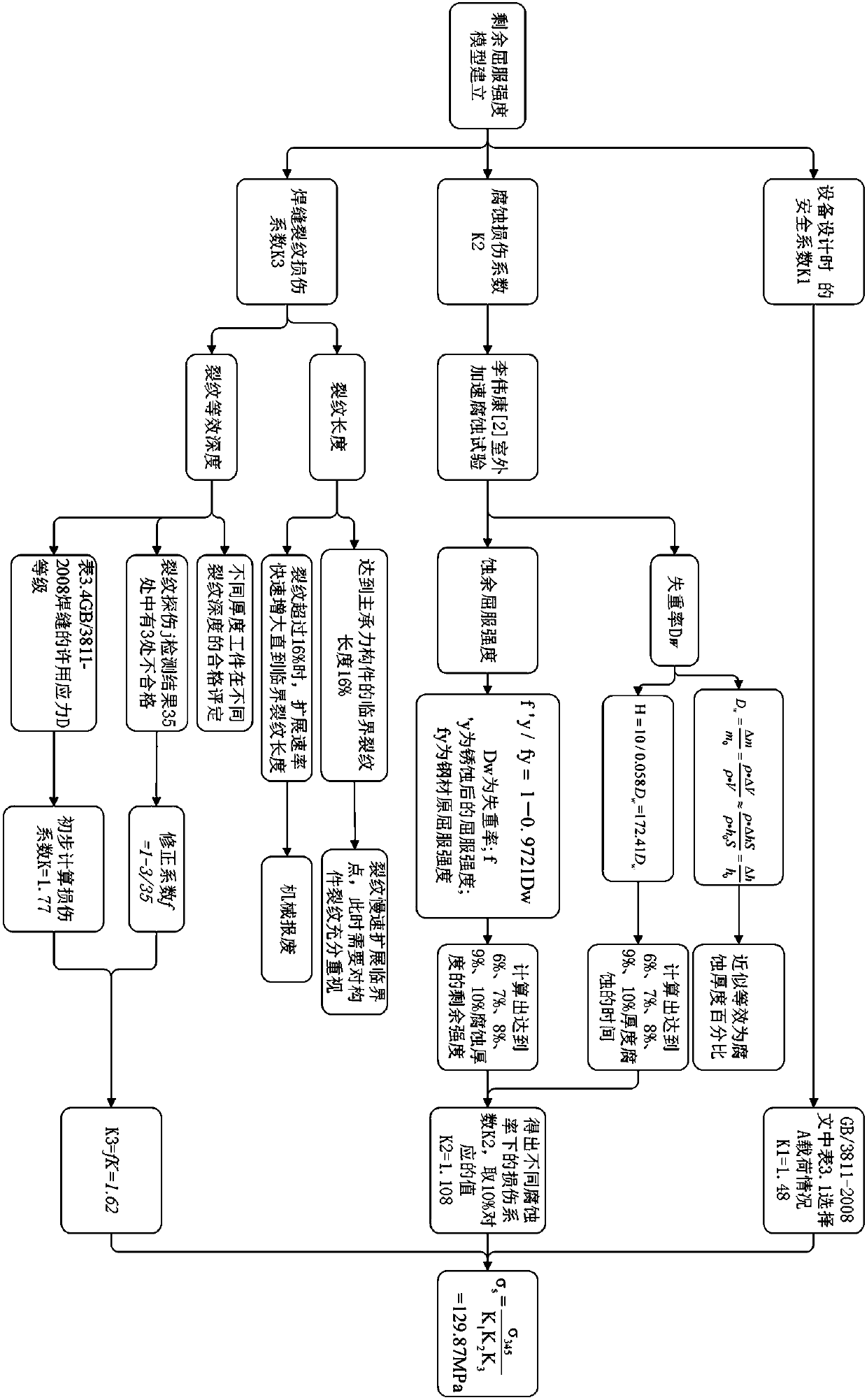

[0085] The remaining fatigue life of the main metal structure is determined by calculating the cumulative damage based on the corrosion damage factor and the weld crack damage factor. The detailed steps are as follows:

[0086] Step 1: Use ANSYS to carry out three-dimensional modeling and simulation of the gantry hoist, and conduct finite element analysis in combination with the actual situation, and it is clear that the middle part of the main beam is a dangerous part of stress concentration.

[0087] Step 2: On-site patching, the actual hoisting dynamic stress test is carried out, and the equivalent stress values under different working conditions are measured.

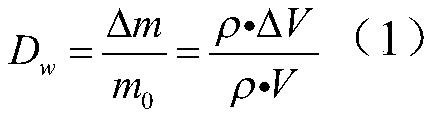

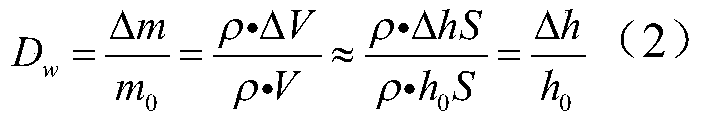

[0088] Step 3: Establish the residual fatigue strength model of the metal structure, find out the safety factor of the structure, calculate the corrosion damage coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com