Duct piece backfilling grouting body core-pulling inspection device and inspection method thereof

A technology of grouting and testing devices behind the wall, which is applied in the direction of sampling devices, material inspection products, and preparation of test samples. The inspection operation is simple and easy to understand, the construction efficiency is high, and the device structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

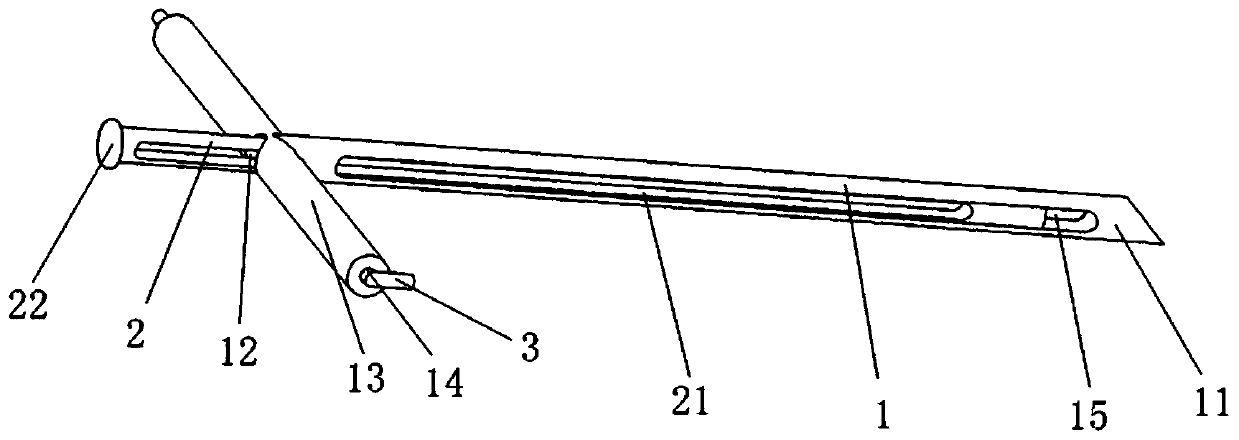

[0027] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0028] A subway shield section project in Guangzhou City, Guangdong Province, the section passes through high-pressure gas pipes, dense building villages, rivers, pedestrian bridges, passenger stations, and high-speed railway stations on the side. There are more than 200 houses and workshops within a width of 60m, some of which are dilapidated, and there is also an ancient well and ancestral hall. This area has high requirements for ground settlement and settlement of heavy structures. If the grouting effect is not ideal, defects such as voids, lack of compactness, and loose layers will easily occur, which will lead to ground subsidence, cracking of the surrounding building structure, and even induce serious disasters such as ground collapse, tunnel collapse, and building collapse. The application of the slurry core-pulling inspection device can ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com