Tool-workpiece contact surface droplet dynamic wetting characteristic detection method and device

A technology of wetting characteristics and detection methods, which is applied in the field of detection of liquid droplet wetting characteristics at the contact surface of the knife-chip, and can solve problems such as unsuitable cutting fluid droplet wetting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing.

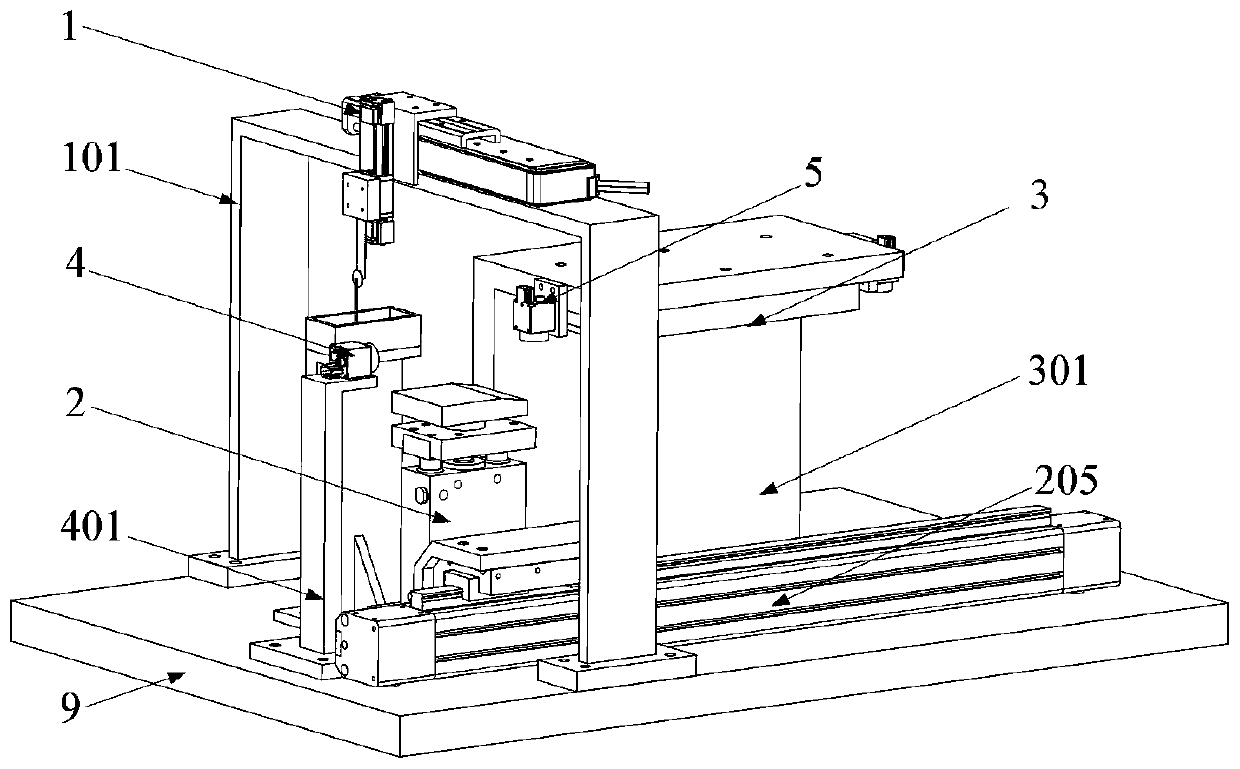

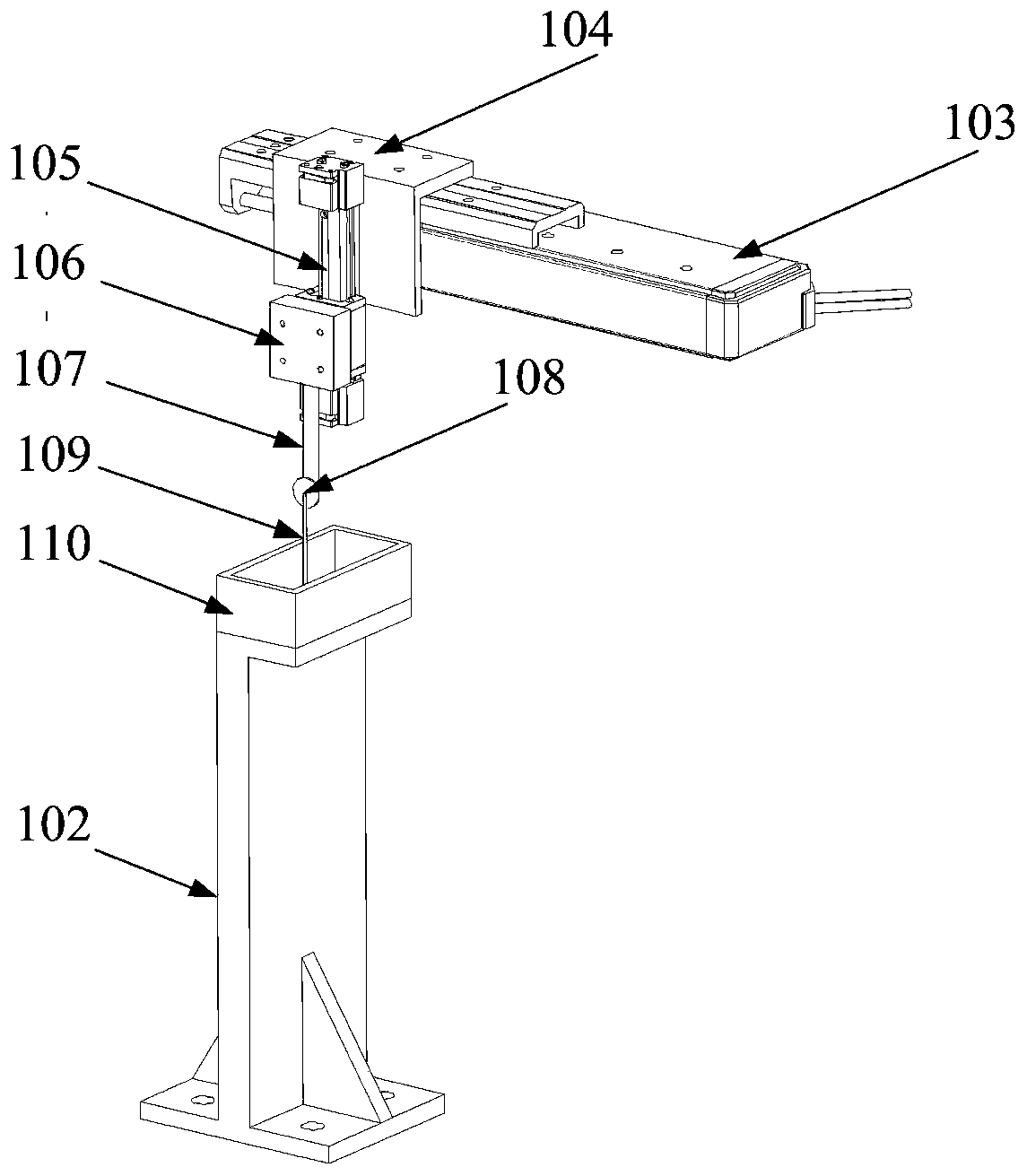

[0052] Such as figure 1 As shown, a device for detecting the dynamic wetting characteristics of droplets on the tool-workpiece interface includes a microdroplet preparation device 1, a tool block feeding device 2, a workpiece block 3, a visual inspection system and a frame. The micro-droplet preparation device 1 and the cutter block feeding device 2 are arranged side by side; The tool block feeder 2 is aligned with the workpiece block 3 . The tool block 201 of the tool block feeding device 2 performs a relative frictional movement with the workpiece block 3 after dripping the liquid drop to be measured, so that the liquid drop is dragged during the friction process to form liquid traces. The frame includes a droplet preparation support 101 , a droplet storage support 102 , a workpiece block installation support 301 and a visual detection camera support 401 . All above su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com