Visual test device and method for shear-seepage coupling failure process

A test device and percolation technology, applied in the direction of applying stable shear force to test material strength, measuring device, using applied stable tension/pressure to test material strength, etc., can solve the problem of low osmotic pressure, invisible shear box, The problem of poor sealing of the shear box is achieved to improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

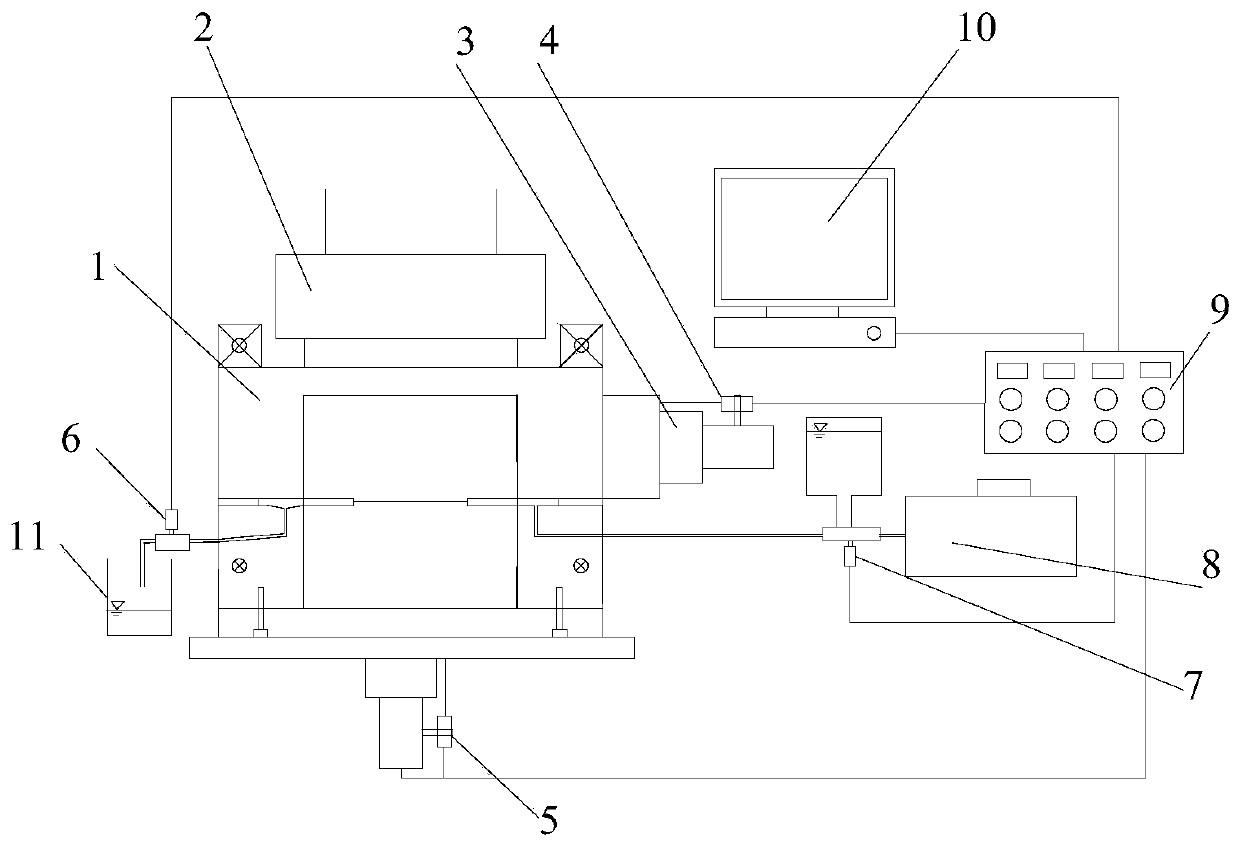

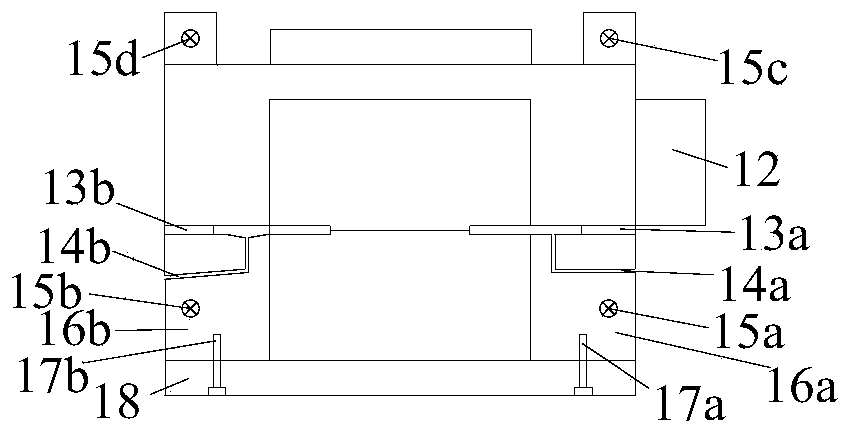

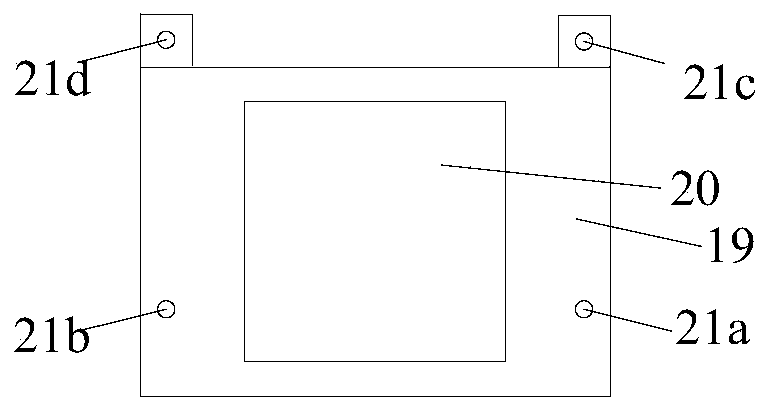

[0033] In a typical embodiment of the present invention, such as figure 1 As shown, a test device for visualizing the failure process of shear-seepage coupling is provided, including an upper shear box 12, a pad, a lower shear box, a pressure loading mechanism, a permeate loading mechanism, a sensor and a controller, and the upper shear box 12 The bottom end of the box 12 is attached to the spacer, and the bottom end of the spacer is attached to the lower shear box, that is, the upper shear box 12 is located at the upper end of the lower shear box, between the upper shear box 12 and the lower shear box. A spacer is provided, and a water inlet 14a and a water outlet 14b are provided on the side where the spacer is attached to the upper shear box 12 or the lower shear box. The permeate loading mechanism is connected to the water inlet 14a, and the pressure loading mechanism can push the upper shear box. The box 12 is used to cut the practice; the sensor is connected to the contr...

Embodiment 2

[0052] In a typical implementation of the present invention, a test method for visualizing the shear-seepage coupling failure process of non-penetrating joint rock mass is also provided, using the test device for visualizing the shear-seepage coupling failure process as described in Example 1 , including the following steps:

[0053] 1) Set up a test device for visualizing the shear-seepage coupling failure process as described in Example 1;

[0054] 2) Use rock-like materials to make non-penetrating jointed rock mass, and perform maintenance after the production is completed;

[0055] 3) Fix the upper shear box 12 and the lower shear box on the test bench, put the non-penetrating jointed rock mass sample, and conduct the shear-seepage coupling test.

[0056] The main components of the rock-like material are gypsum and cement, which are mixed evenly with water in a certain proportion, put into the corresponding mold to complete the sample production, and then the sample can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com