Electronic water pump magnetic transmission device for automobile

A technology of electronic water pump and magnetic drive, which is applied to pump devices, electromechanical devices, components of pumping devices for elastic fluids, etc. It can solve the problems of impossibility of immersion, increased rotation noise, and large frictional resistance inside the bearing, etc., to achieve Improve working stability, reduce frictional resistance, and improve bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

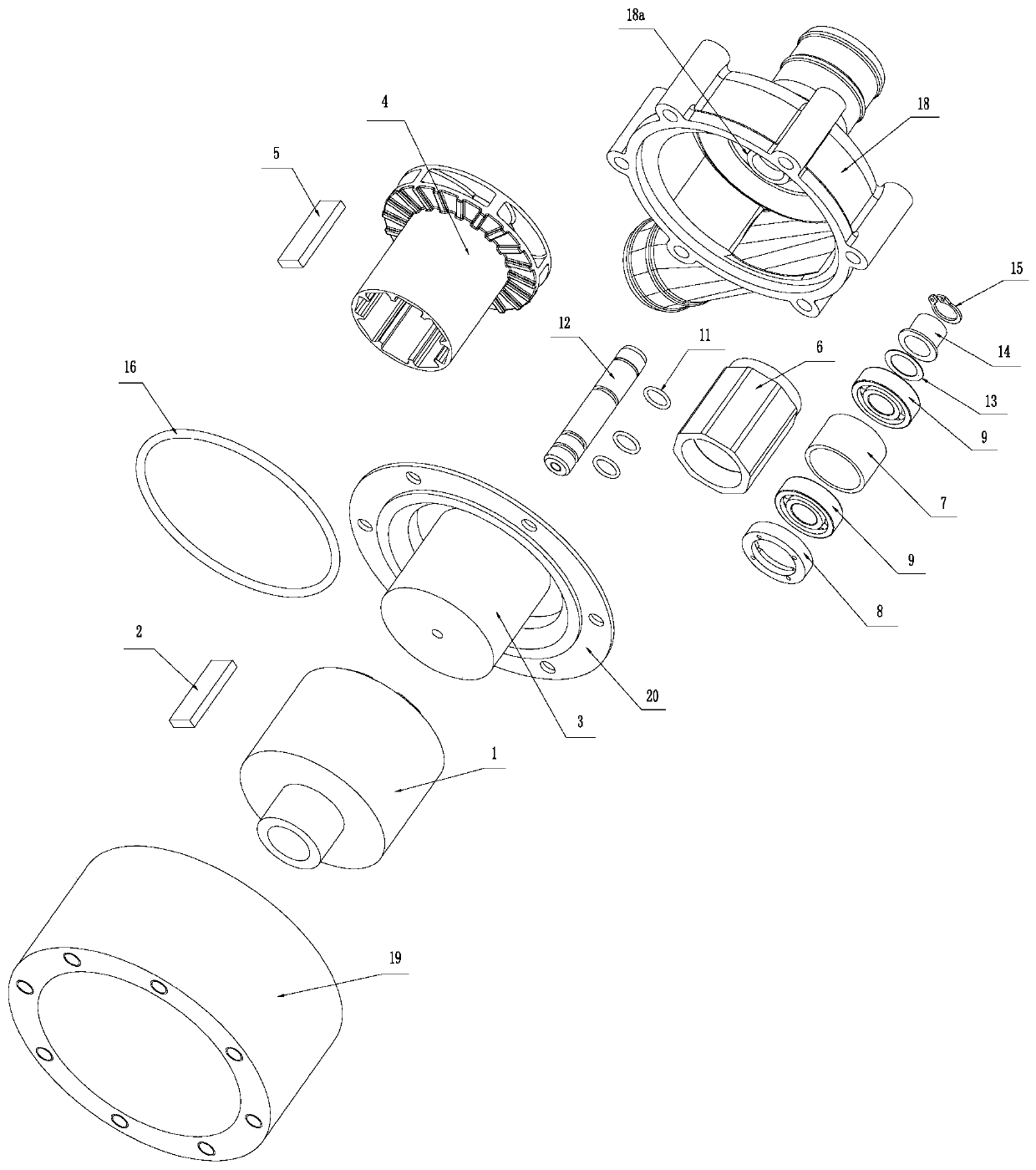

[0028] Embodiment: combine below figure 1 and figure 2 The specific implementation of the electronic water pump magnetic drive device for automobiles provided by the present invention is described as follows:

[0029] First of all, it has the pump head shell 18, the connection shell 19 and the non-metallic spacer 3 as in the conventional technology. The pump head shell 18 is located at the front end, and the connection shell 19 is located at the rear. There is a connecting ring 20 extending between the pump head shell 18 and the connecting shell 19, and the connecting ring 20 on the pump head shell 18, the connecting shell 19 and the non-metallic spacer 3 is provided with a total of 6 positioning holes corresponding to one week ( figure 2 not marked). During actual assembly, the connecting ring 20 and the pump head casing 18 are locked and fixed to the connecting casing 19 together by passing through six connecting casing connecting screws 17 . and if figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com