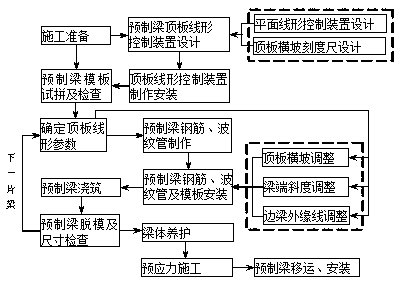

Precast beam top plate linear control construction method

A technology of linear control and construction method, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems affecting the appearance of bridges, affecting structural quality and safety, etc., and achieves reduced construction survey costs, high formwork control accuracy, and improved The effect of linear quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

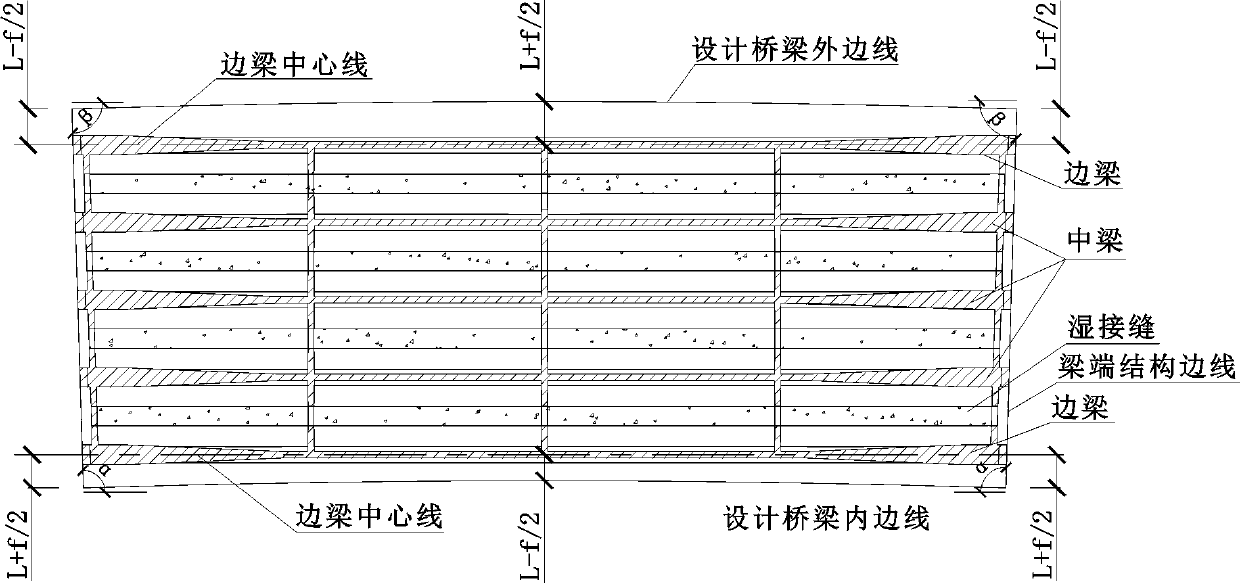

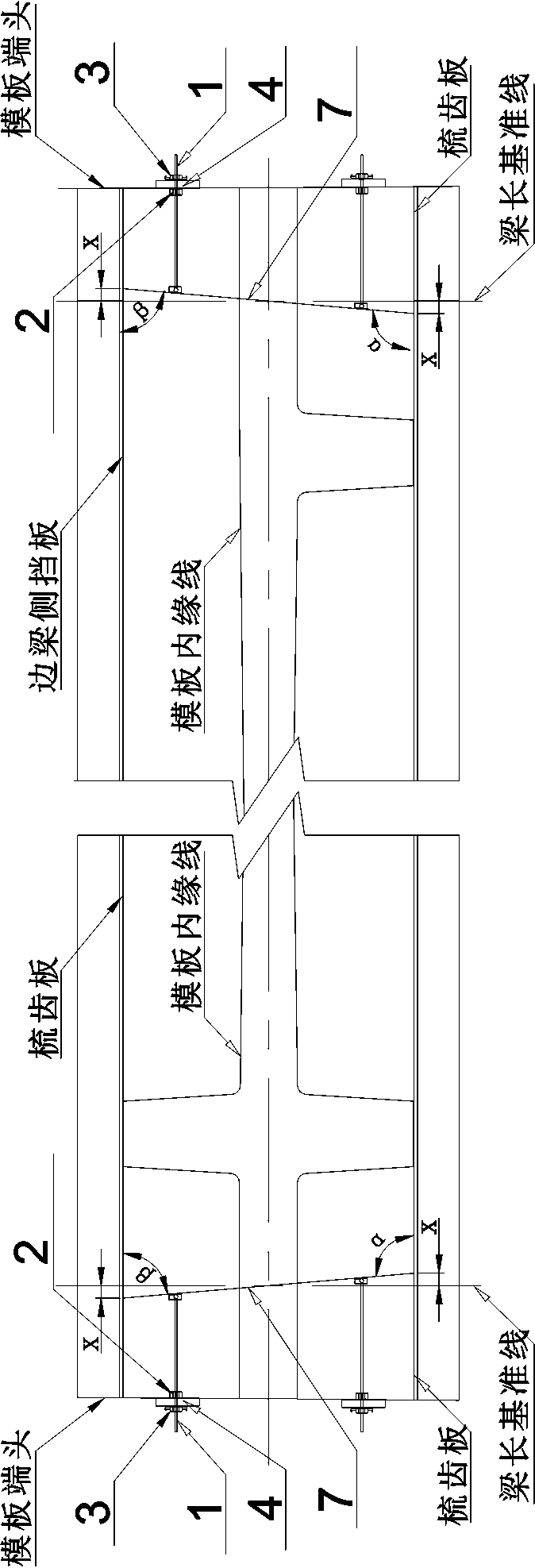

[0124] Project example: The bidding section LJ15 of Renshou-Pingshan Xinshi Highway, undertaken by Sichuan Luhang Construction Engineering Co., Ltd., is located in Zhongdu Town, Pingshan County, Yibin City. Three bridges, including Zhongduhe Super Bridge and Huangjueba Bridge, are flat section bridges with small radius and large arc. In the process of bridge prefabrication, the project department carried out innovative transformation of the prefabricated beam formwork, designed and manufactured the beam end slope adjustment device, the side beam top plate outer edge line shape adjustment device, the beam top cross slope adjustment scale device, etc. for the prefabricated beam top plate Alignment control, forming a prefabricated beam roof alignment control construction method. After adopting this construction method, the linear shape of the prefabricated beam roof has been significantly improved, and the construction procedure has also been simplified, and the operation is simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com