Cable winding device for power distribution engineering

A winding device and cable technology, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of tight fit of the winding device, time-consuming and labor-intensive cables, and heavy weight of the cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

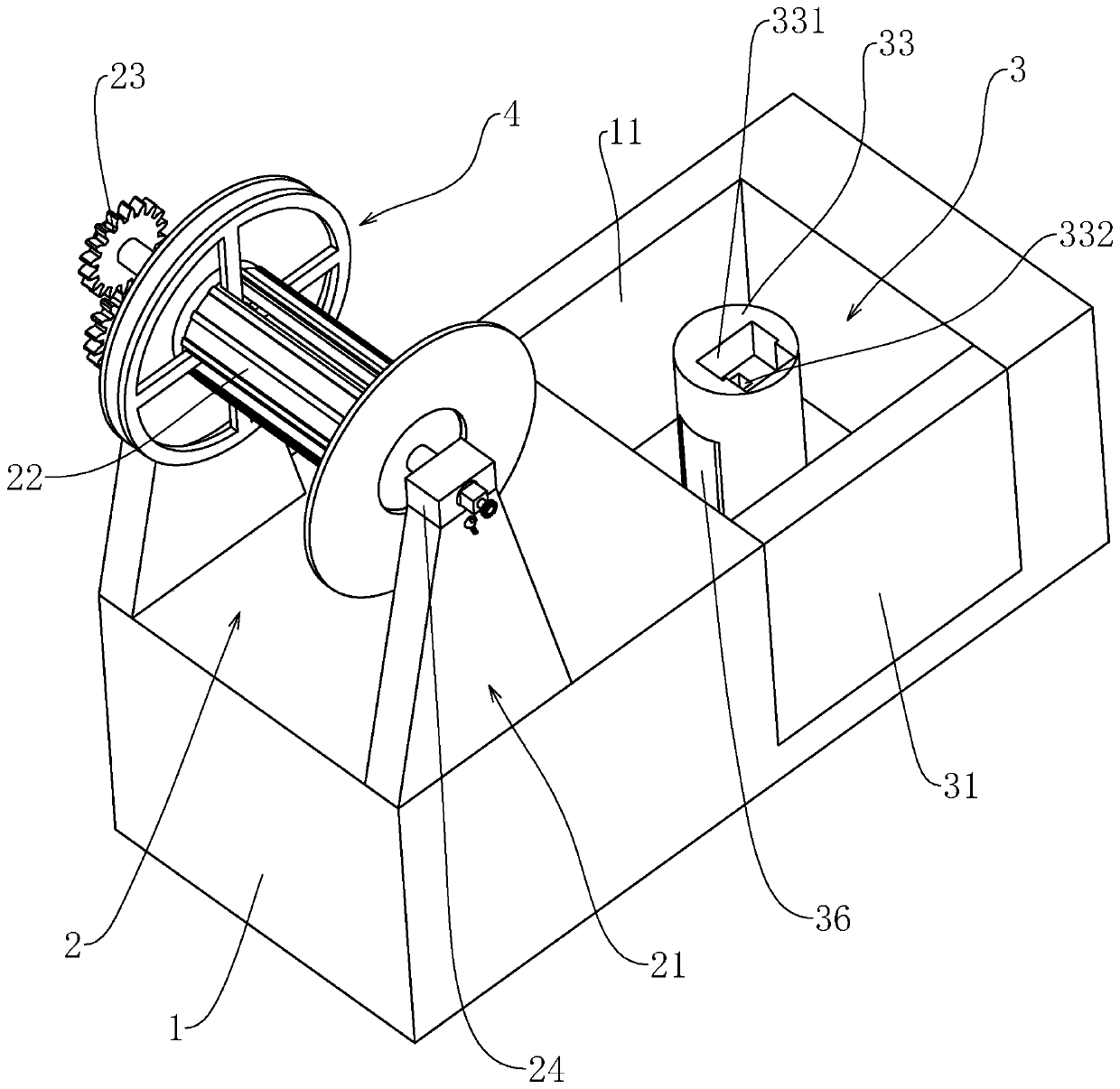

[0030] This embodiment discloses a cable winding device for power distribution engineering, such as figure 1 As shown, the base 1 is included, and the upper end of the base 1 is provided with a winding mechanism 2 and a dismounting mechanism 3. The winding assembly includes a support frame 21 fixed on the base 1, and the support frame 21 is rotatably connected with a winding shaft 22. A drive assembly 23 is installed on the side, and a material shifting mechanism 4 is installed on the winding shaft 22 .

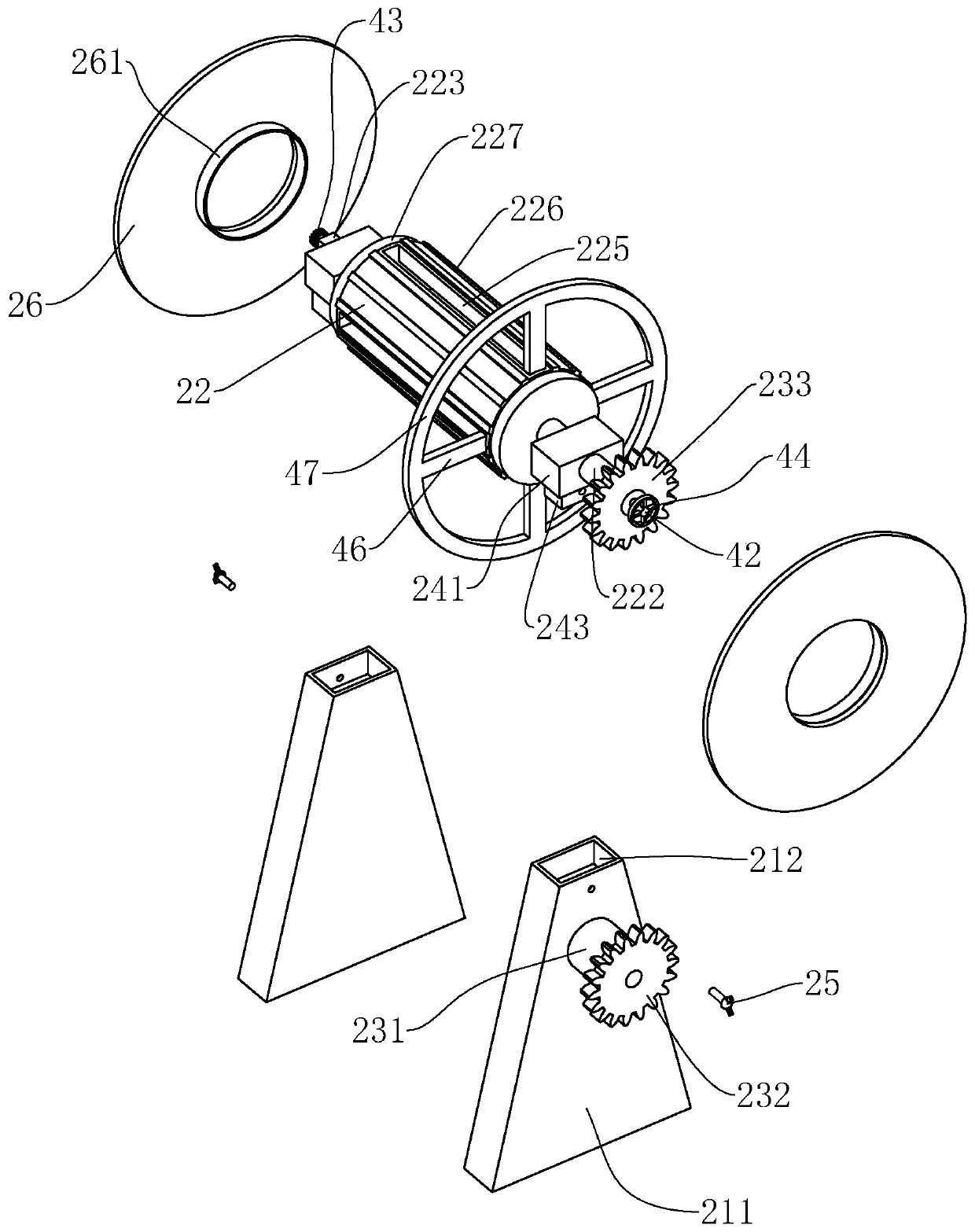

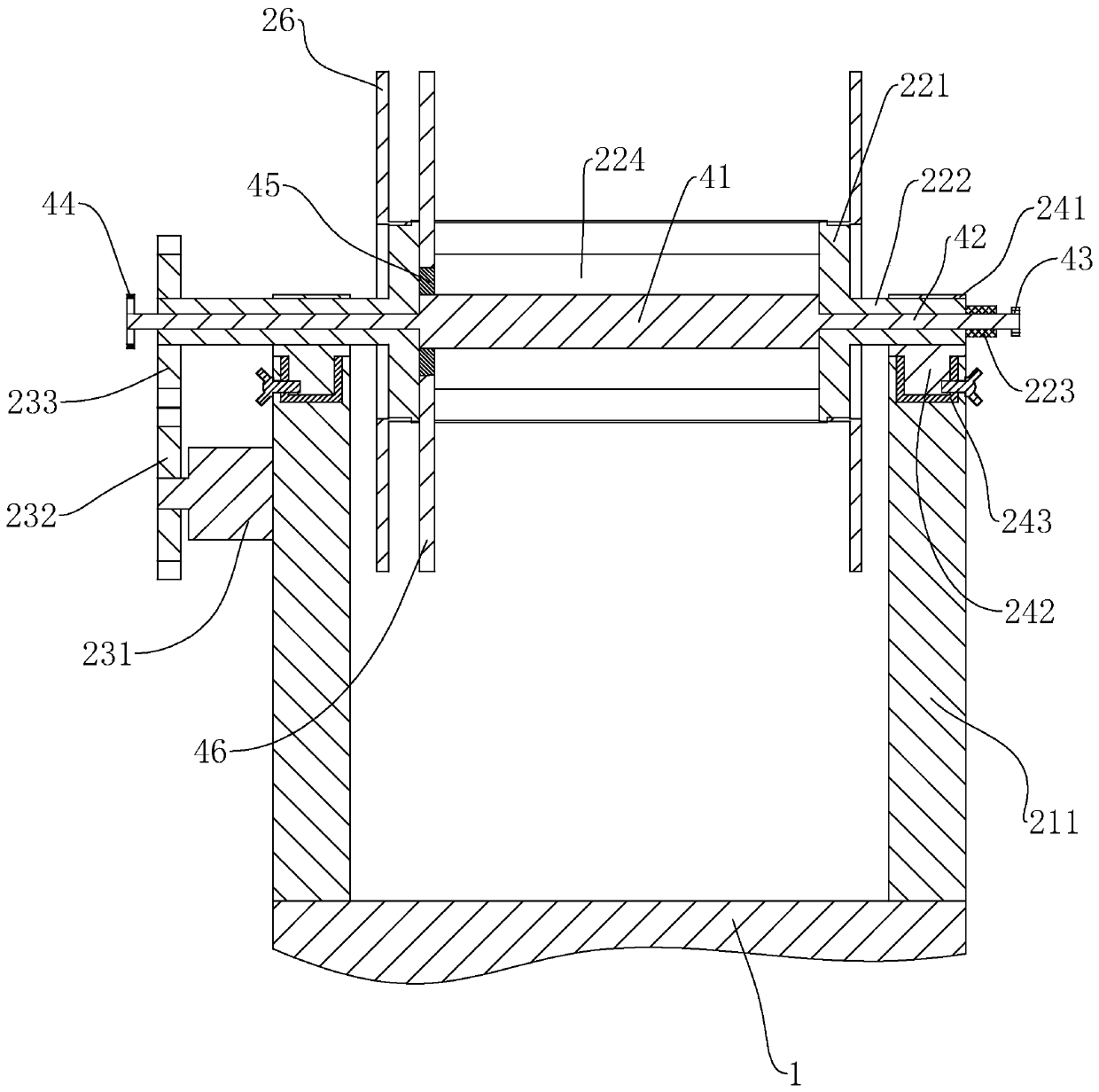

[0031] Such as figure 2 , image 3 As shown, the winding shaft 22 includes a central shaft 221, the two ends of the central shaft 221 are fixed with a rotating shaft 222, and the rotating shaft 222 is connected with a mounting block 24 for rotation, and the two ends of the central shaft 221 are larger than the mounting block 24. The support frame 21 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com