A method for calibrating vehicle instrument configuration parameters

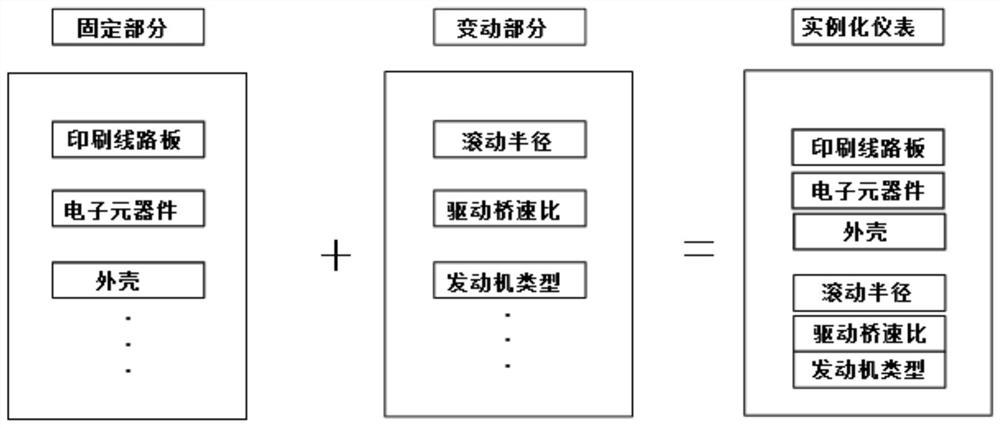

A technology for parameter calibration and instrument configuration, which is applied in motor vehicles, vehicle components, digital transmission systems, etc., can solve the problems of easy assembly errors, increased management costs, and cumbersome after-sales maintenance, and achieves the effect of reducing the number and improving the generalization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0022] Such as figure 1 The vehicle meter configuration parameter calibration method shown is characterized in that it includes the following steps:

[0023] Step 1: Power on the ignition switch of the whole vehicle, the calibration device sends a request to the vehicle instrument to enter the extended mode, and the vehicle instrument replies to enter the extended mode;

[0024] Step 2: The calibration device sends a random number request to the vehicle instrument, and the vehicle instrument returns the random number information to the calibration device after receiving the request;

[0025] Step 3: The calibration device assembles the random number information into plaintext (plaintext = random number + fixed value, such as: the random number is 0xFAFB1245, the fixed value is 0xACBF1146, then the plaintext = 0xFAFB1245 ACBF1146) and performs encryptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com