An intelligent injection mold

An injection mold and mold cavity technology, applied in the field of injection mold structure improvement, can solve problems such as affecting production efficiency, time-consuming, complicated installation and disassembly process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

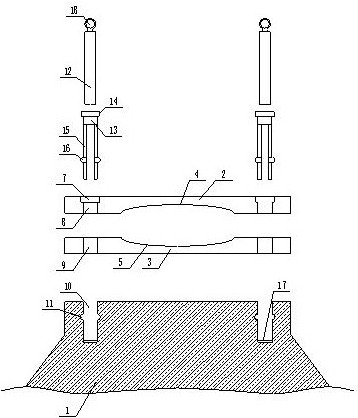

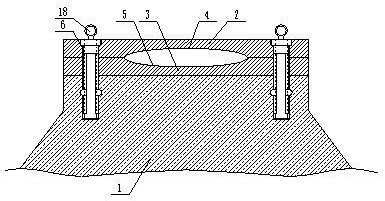

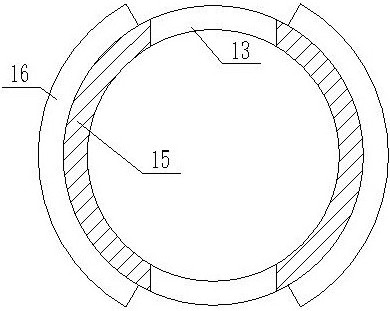

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, the inventive point of the present application is that the upper mold is provided with a plurality of through holes-6, the through holes communicate with the upper and lower surfaces of the upper mold, and the plurality of through holes-the center line of the upper mold is equiangular distribution On the upper die, the through hole one is formed by connecting a thick cylindrical hole 7 and a thin cylindrical hole 8, and the center line of the thick cylindrical hole and the center line of the thin cylindrical hole are in a line On a vertical line, the thick cylindrical hole communicates with the upper surface of the upper die, and the thin cylindrical hole communicates with the lower surface of the upper die;

[0026] The inventive point of the present application is also that the lower mold is provided with a plurality of through holes 9, and the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com