Auxiliary glue spreading equipment for square glass window

A glass window and square technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problems of low gluing efficiency, uneven gluing, poor placement of glass windows, etc., and achieve saving Operation steps, easy to cooperate with the operation, easy to fix the effect of the glass window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

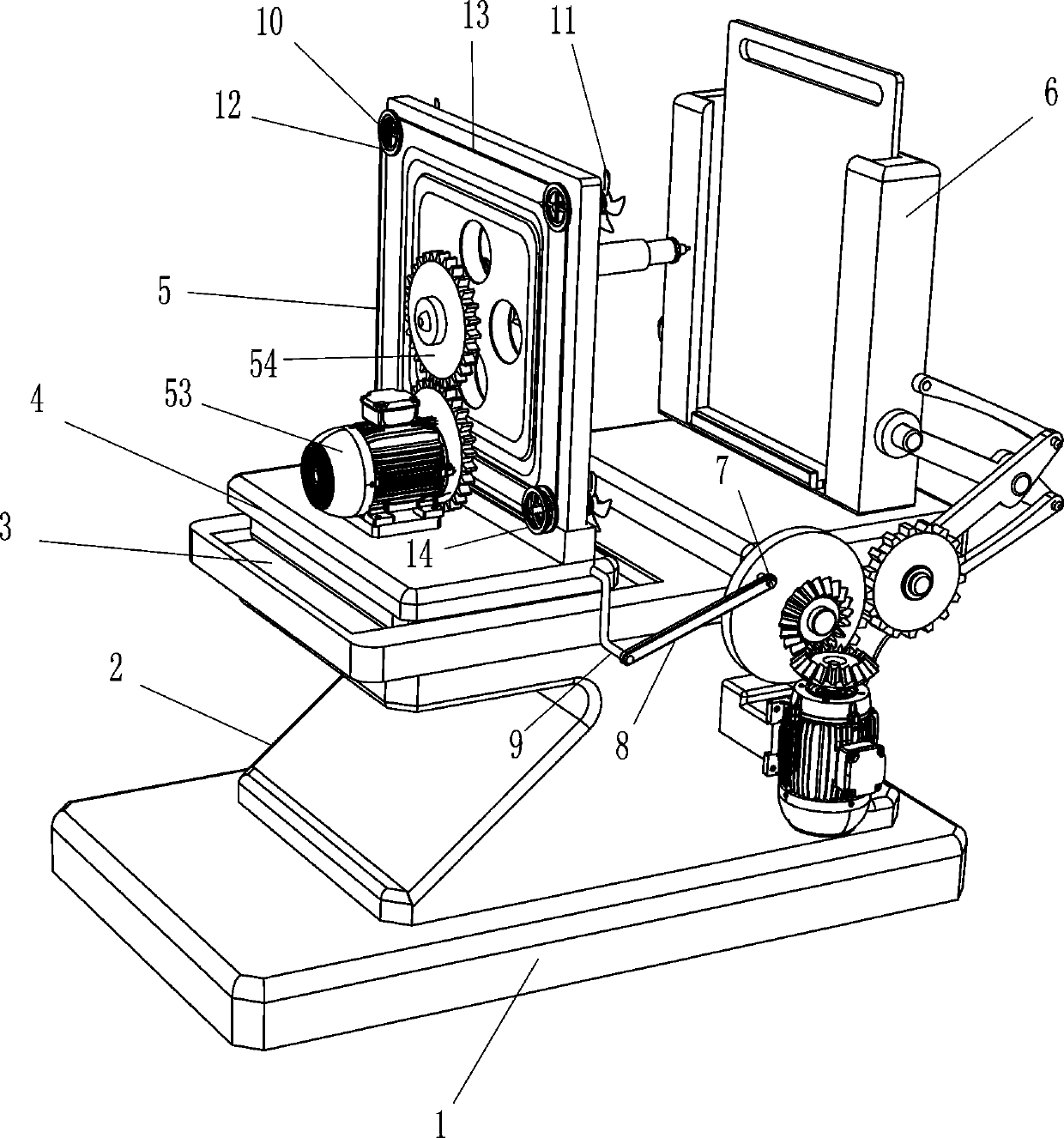

[0021] Such as Figure 1-4 As shown, an auxiliary gluing equipment for square glass windows includes a bottom plate 1, a workbench 2, a sliding plate 4, a gluing mechanism 5, and a turning and placing mechanism 6. The bottom plate 1 is provided with a workbench 2, and the top left of the workbench There is a chute 3 on the side, and a sliding plate 4 is installed in the chute 3. The top of the sliding plate 4 is equipped with a gluing mechanism 5 for automatically gluing the glass windows. Turn over the placement mechanism 6.

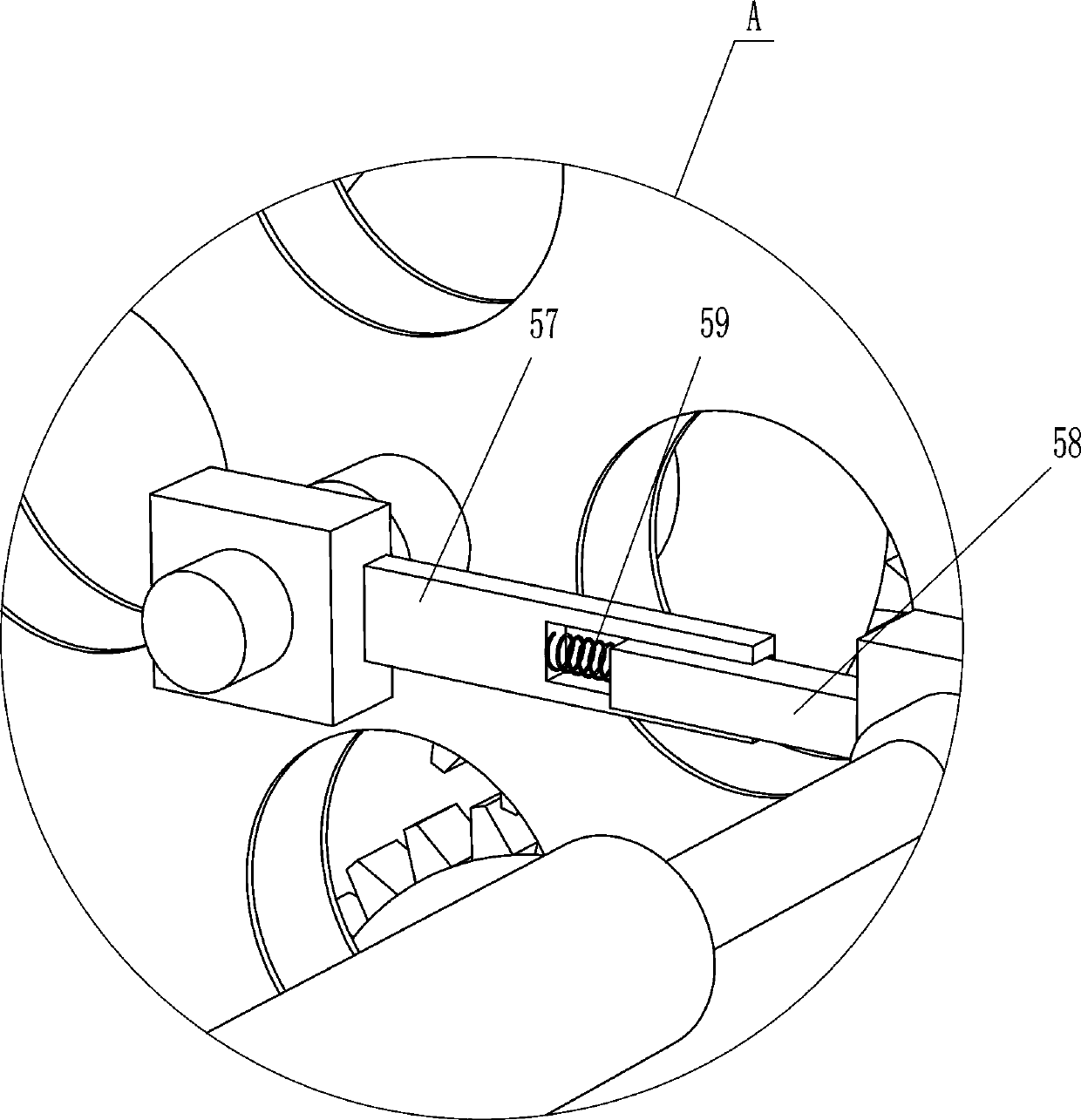

[0022] The gluing mechanism 5 includes a square plate 51, a first rotating shaft 52, a rotating motor 53, a first circular gear 54, a square track 55, a cylindrical slider 56, a square cover plate 57, a square rod 58, an elastic member 59 and a glue gun 510 The right side of the top of the sliding plate 4 is provided with a square plate 51, the middle part of the square plate 51 is rotatably provided with a first rotating shaft 52, the center of the to...

Embodiment 2

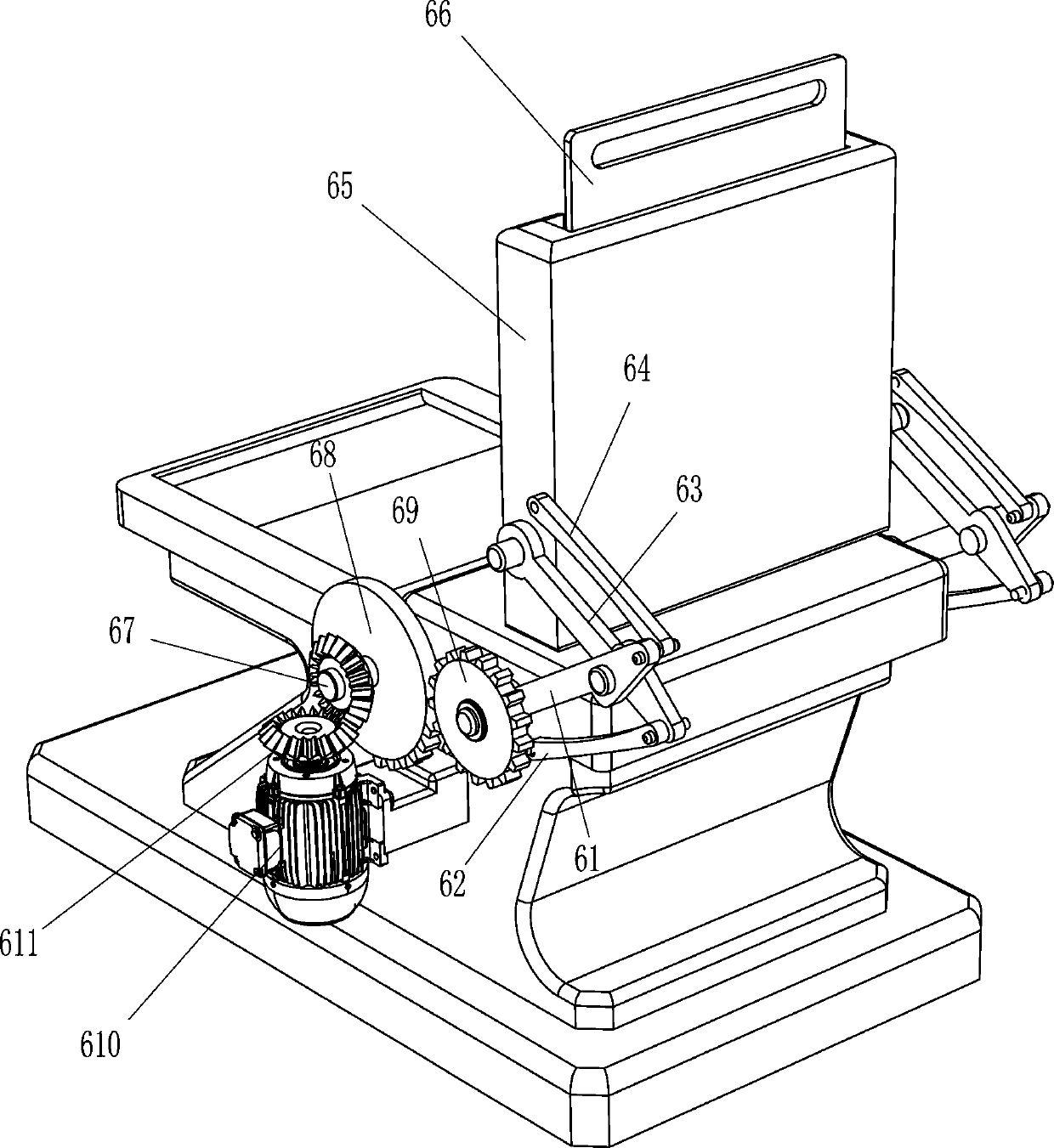

[0026] Such as figure 1As shown, on the basis of Embodiment 1, it also includes a first rotating shaft 7, a connecting rod 8 and a special-shaped frame 9, and the front side of the missing gear 68 is eccentrically provided with the first rotating shaft 7, and the first rotating shaft 7 is rotated A connecting rod 8 is provided, and a special-shaped frame 9 is arranged on the right part of the front side of the sliding plate 4, and the special-shaped frame 9 is connected with the other end of the connecting rod 8 in a rotational manner. When the staff controls the servo motor 610 to rotate counterclockwise, the bevel gears 611 mesh with each other and rotate, and then the missing gear 68 rotates clockwise, and the missing gear 68 rotates clockwise and moves to the right through the connecting rod 8, which is driven by the special-shaped frame 9 The sliding plate 4 moves to the right on the chute 3 on the workbench 2. When the staff controls the servo motor 610 to stop working, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com