Efficient stirring device for feed production and mixing

A technology of mixing device and feed, applied in feed, mixer accessories, application and other directions, can solve the problems of poor mixing effect, incomplete cleaning, low curing efficiency, etc., achieve good mixing effect, improve curing processing efficiency, and improve mixing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

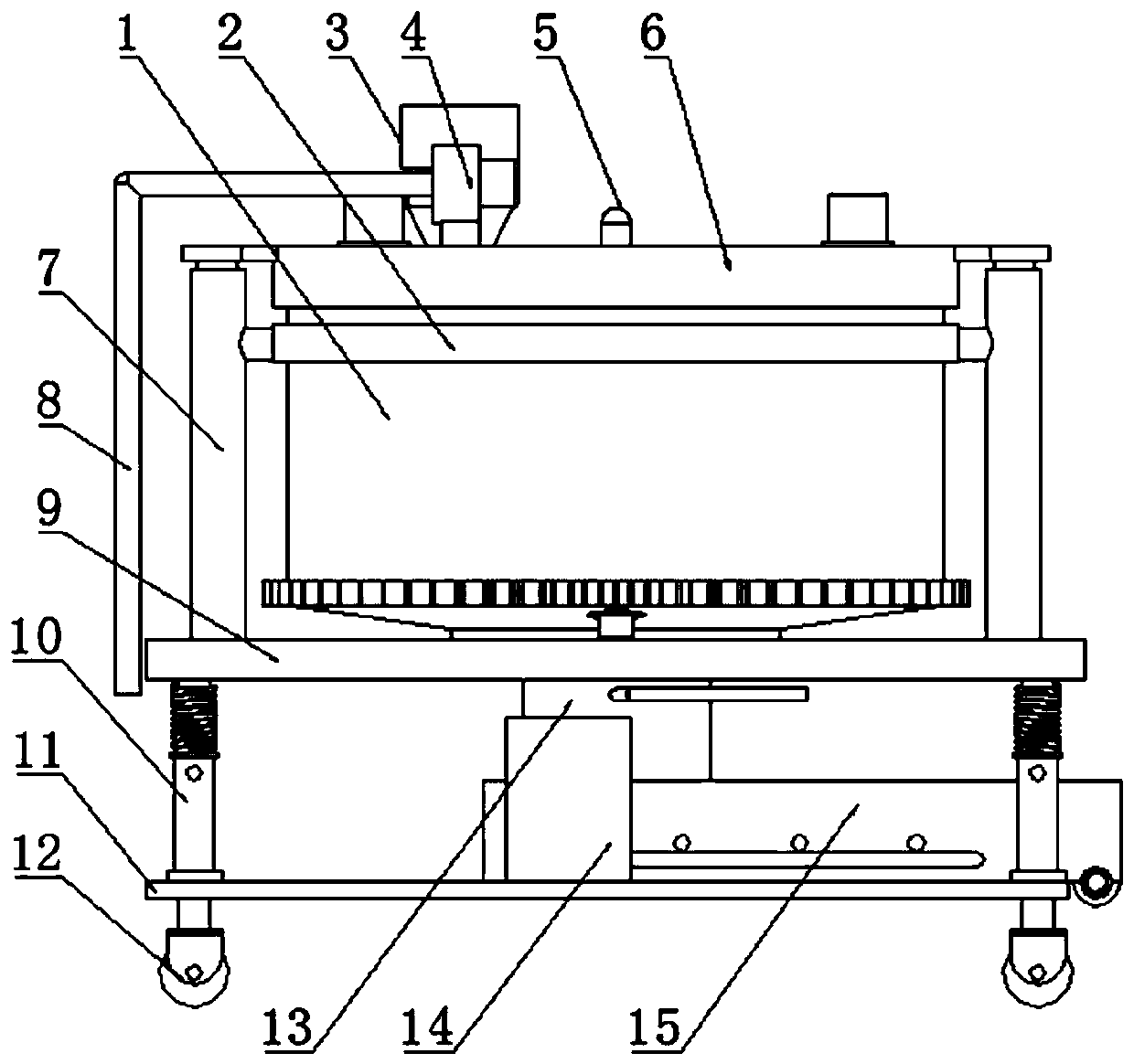

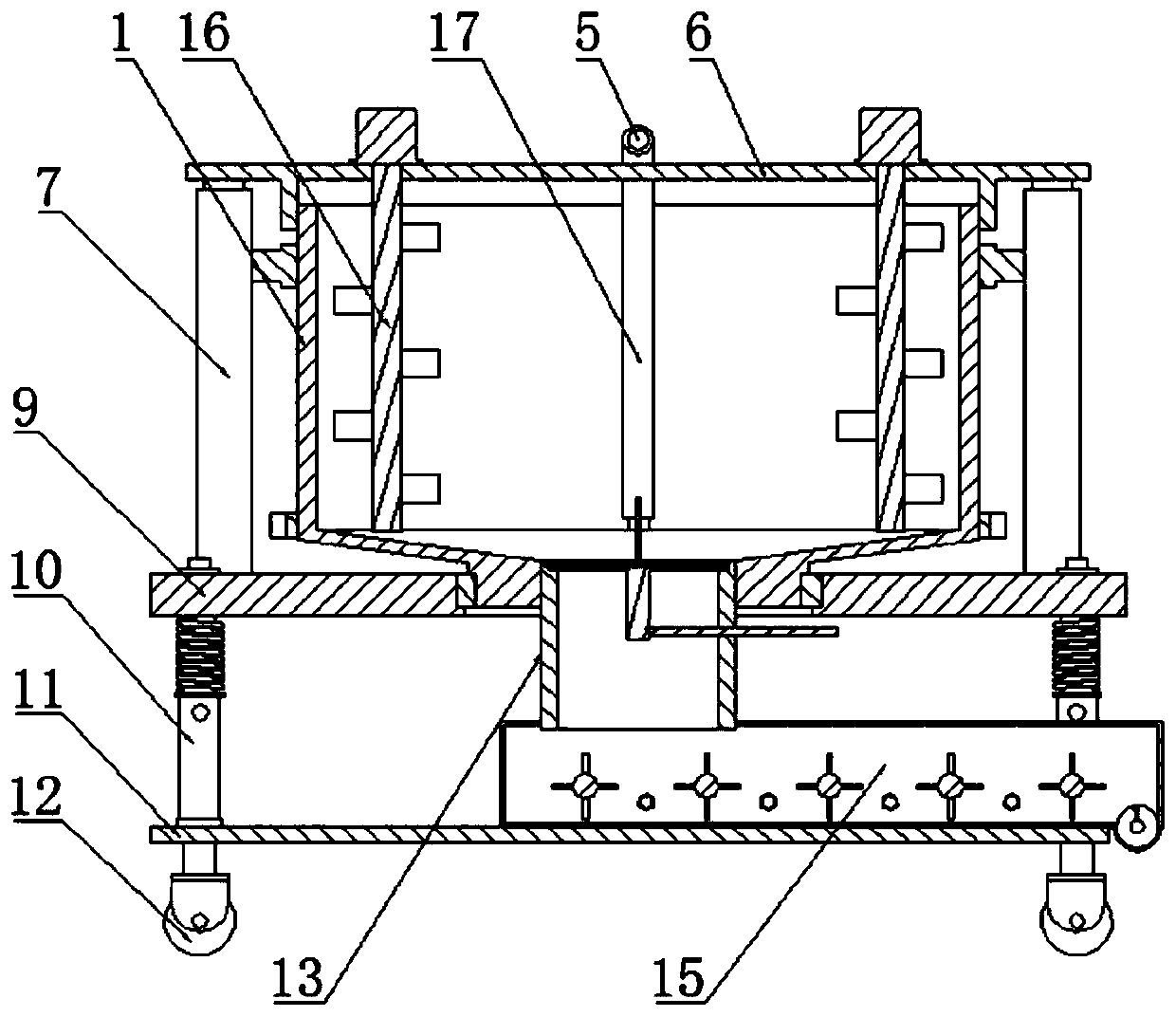

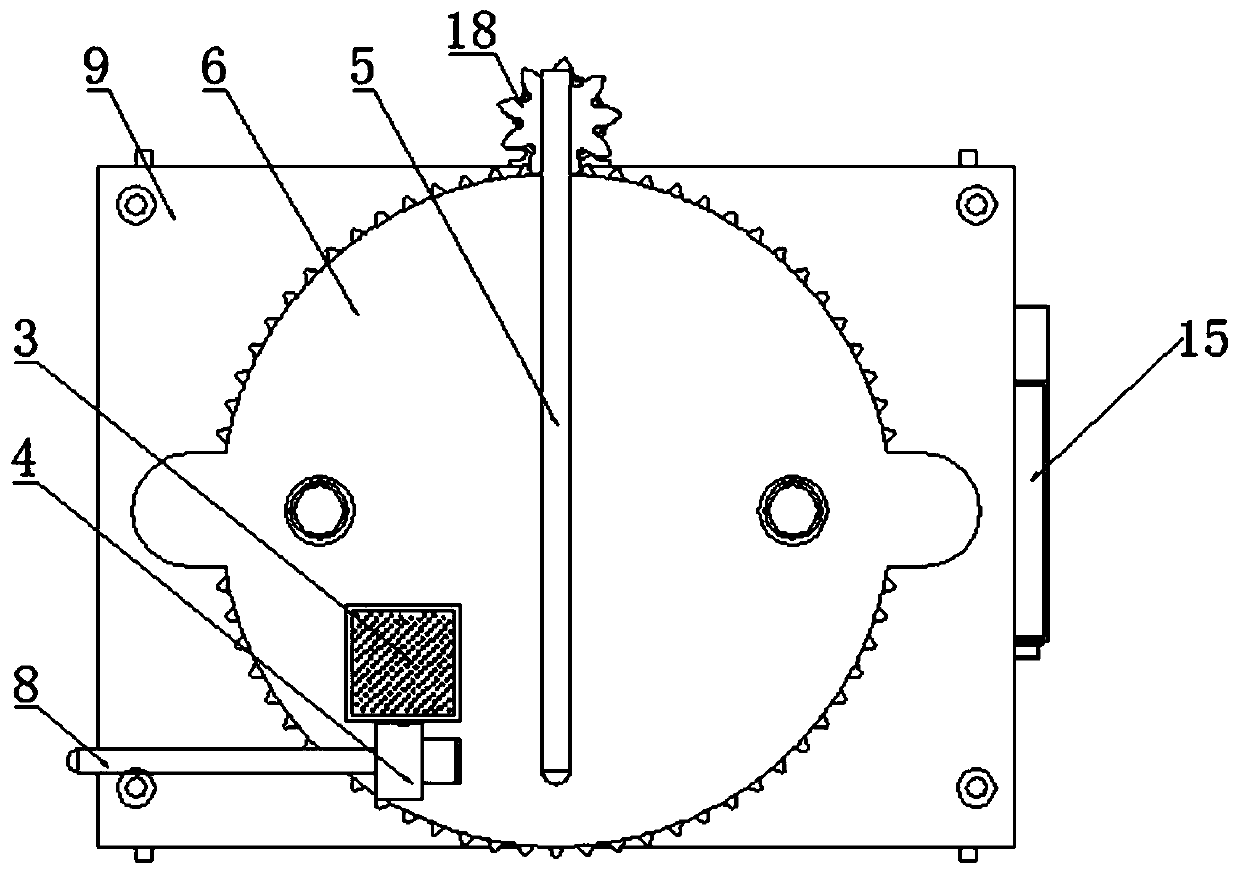

[0031] Example 1, please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a mixing device for high-efficiency feed production, comprising a mixing tank 1, a suction machine 4, a lifting rod 7 and a steam generator 14, the upper end mask of the mixing tank 1 is provided with a tank cover 6, and the lower end of the mixing tank 1 is provided with Support plate 9 is arranged, and support plate 9 realizes the support fixing to mixing tank 1, and the left and right sides of mixing tank 1 is all provided with vertical elevating rod 7, and the lower end of elevating rod 7 is fixed on the supporting plate 9, and elevating rod 7 The upper end ejector rod is fixedly connected with the left and right ends of the tank cover 6, and the tank cover 6 is driven to rise by the lifting rod 7 to facilitate cleaning of the mixing tank 1. A bottom plate 11 is arranged below the support plate 9, and the support plate 9 and the bottom plate 11 There are support columns 10 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com