Connecting system for installing ALC light partition walls on brick masonry

A connection system and brick masonry technology, applied in the field of building construction, can solve the problems of weak connection, weak connection between ALC lightweight partition wall and brick masonry, etc., to improve firmness, ensure stability, and ensure firmness and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

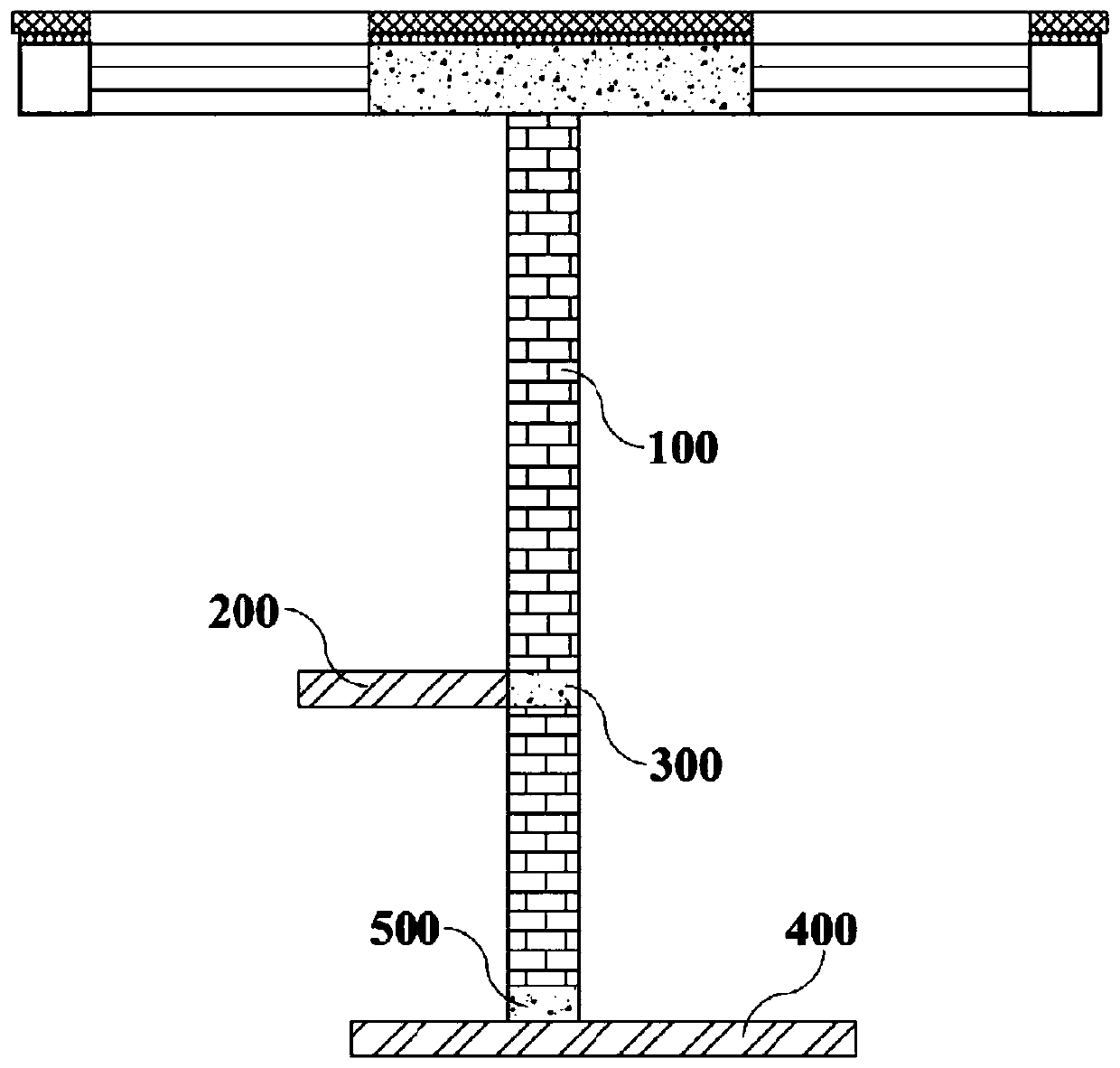

[0033] A connection system for installing ALC lightweight partition walls on brickwork in this embodiment, such as figure 1 As shown, it includes a brickwork 100, a first ALC lightweight partition wall 200 and a second ALC lightweight partition wall 400, wherein one end of the first ALC lightweight partition wall 200 is connected to the middle of the brickwork 100, The second ALC lightweight partition wall 400 is located at the bottom of the brickwork 100 , and the brickwork 100 is connected to the middle of the second ALC lightweight partition wall 400 .

[0034] In order to realize the connection between the above-mentioned brickwork 100 and the ALC lightweight partition wall, in the prior art, mortar is generally used for connection, although cement mortar can realize the effective connection between the two in a short time, but with time Extended, the external environment is constantly changing, and the firmness of the connection between the two is gradually weakened, resu...

Embodiment 2

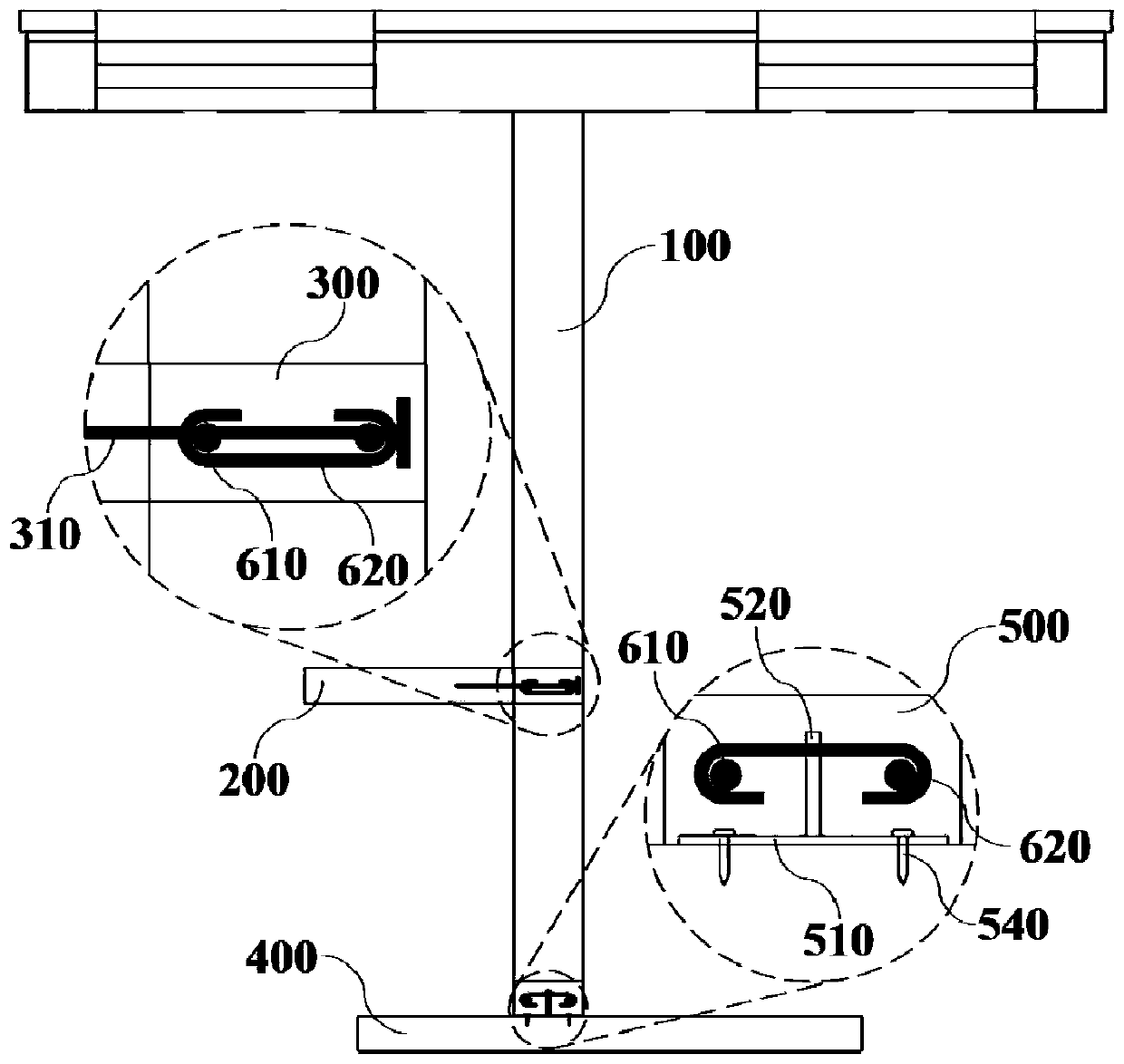

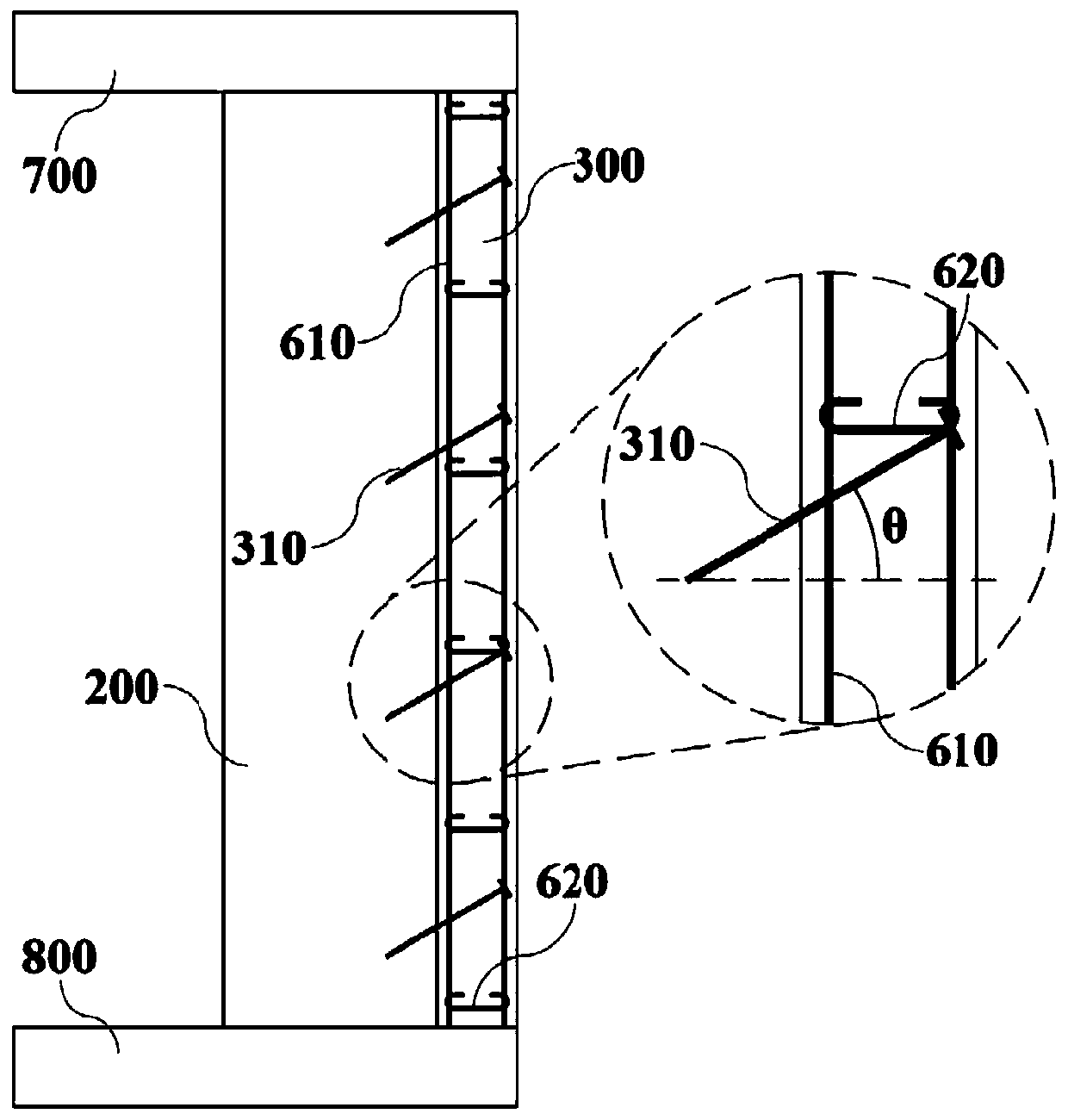

[0044] A connection system for installing ALC lightweight partition walls on brickwork in this embodiment is basically the same as that in Embodiment 1, with a further step: combining figure 2 and image 3 , there are multiple T-shaped steel bars 310 in this embodiment, and multiple T-shaped steel bars 310 are arranged at equal intervals along the length direction of No. 1 secondary structural column 300. When the first ALC lightweight partition wall 200 is installed, The head is connected to the No. 1 secondary structural column 300, and its end mainly bears the force. Therefore, the T-shaped steel bars 310 are evenly distributed, so that the T-shaped steel bars 310 are more evenly stressed, thereby ensuring that the first ALC lightweight partition wall 200 ends head mounting stability.

[0045] When the T-shaped steel bar 310 is nailed, its nailing angle θ is controlled, such as image 3 As shown, the value of θ is 20°-45°, and may be 20°, 25°, 30°...40°...45°.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com