Backfill area foundation pit supporting structure and construction method thereof

A foundation pit support and construction method technology, applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of long time consumption, increased construction cost, and difficult drilling, so as to increase anti-overturning ability and save Construction cost, effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

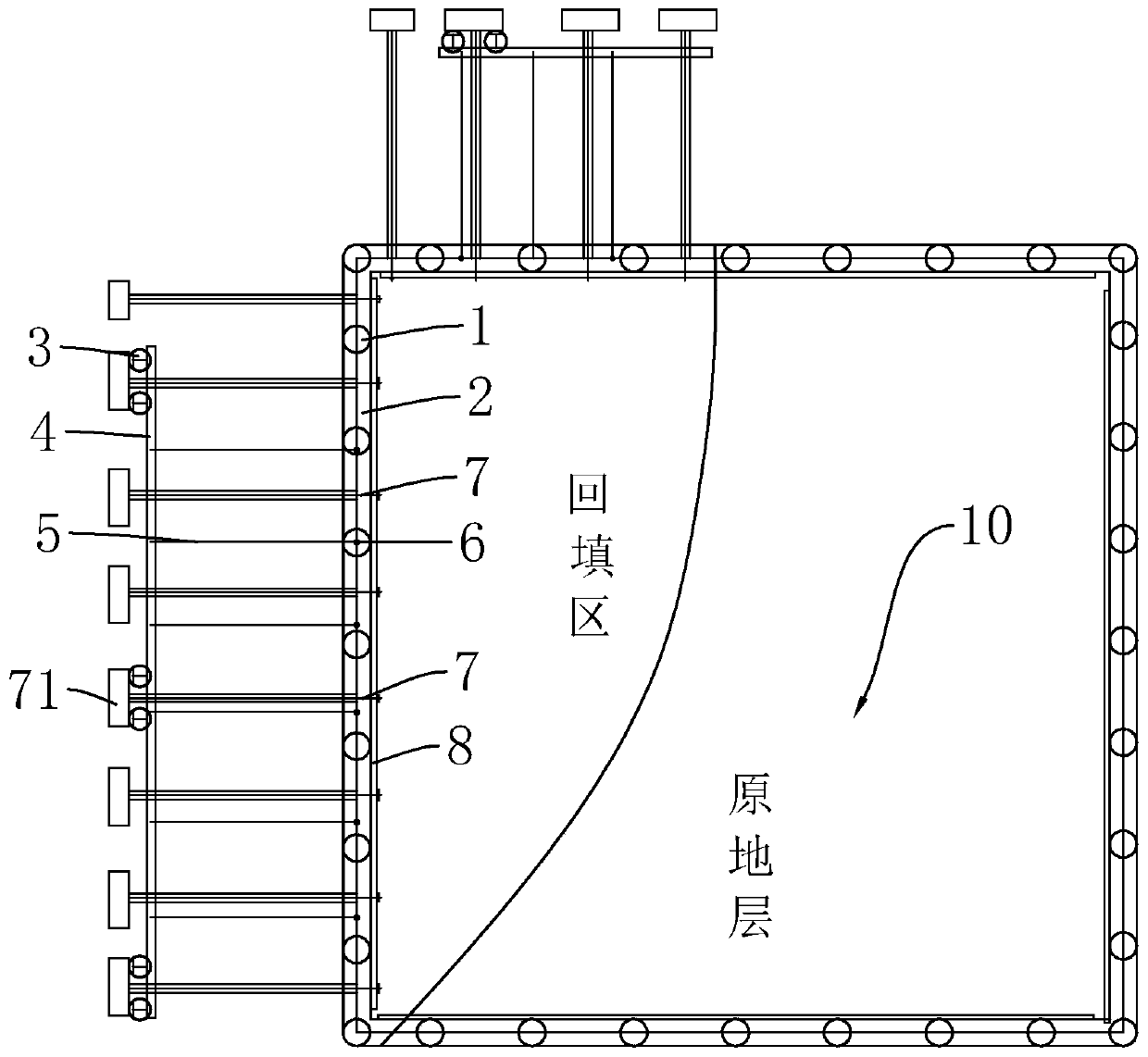

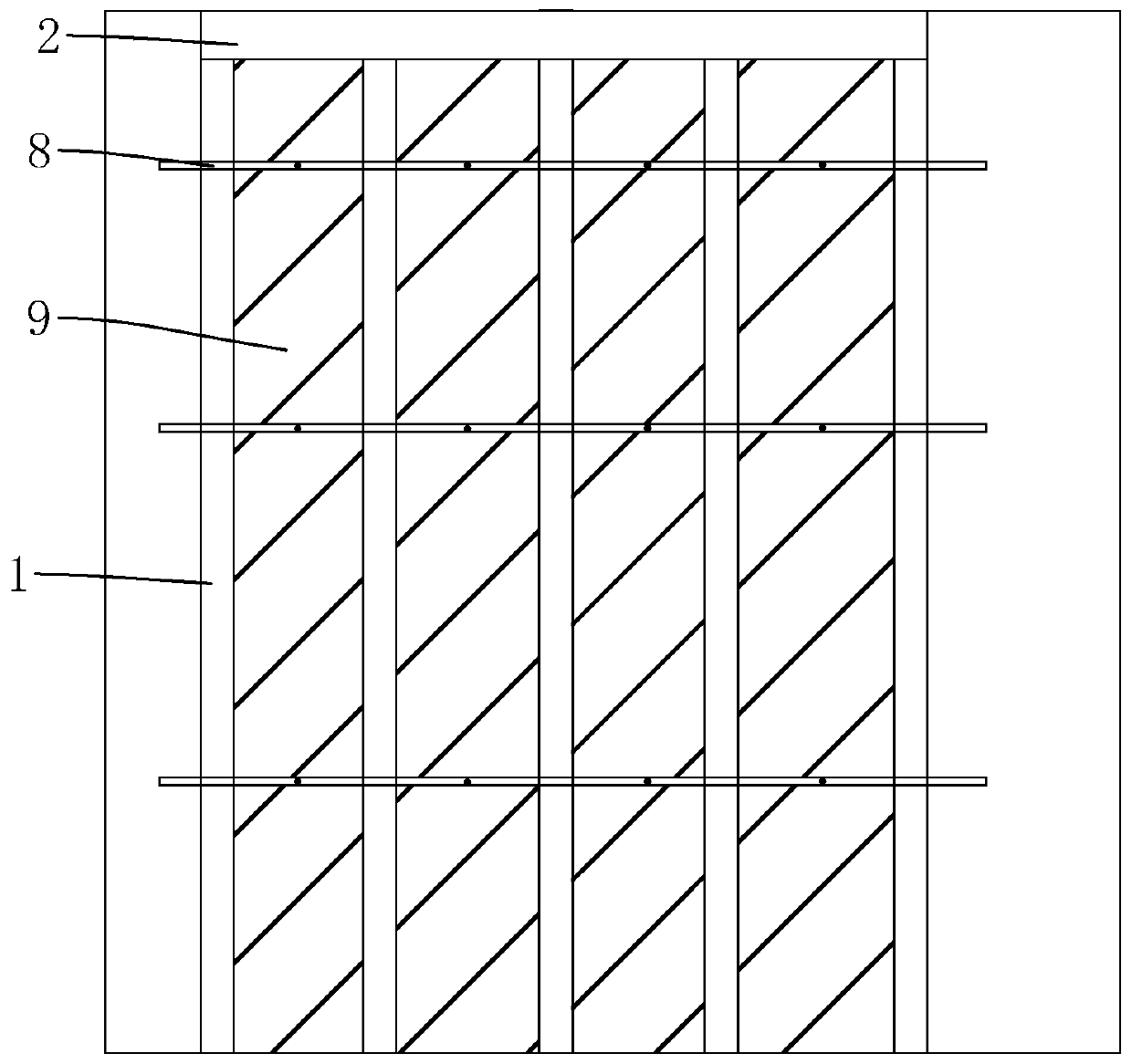

[0038] refer to figure 1 and figure 2 , is a construction method of foundation pit support structure in backfill area disclosed by the present invention, taking the actual construction case foundation pit depth of 14-15m, slope protection pile 1 length of 18-20m as an example. It should be noted that the foundation pit at the normal stratum adopts the normal pile-anchor support method, and the foundation pit at the backfill area adopts the following support method, and the construction steps are as follows:

[0039] S1. Construct the slope protection pile 1 and the crown beam 2 along the surroundings of the foundation pit 10 to be excavated. The specific construction steps are as follows: lay out the line according to the design position and mark the center position of the slope protection pile 1, and the center distance between adjacent slope protection pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com