A kind of dust removal system for warp knitting machine

A dust removal system and warp knitting machine technology, applied in the field of knitting equipment, can solve the problems of poor dust removal effect and unsuitable dust removal system for actual use, and achieve the effects of improving the effect of flying flower suction, reducing energy consumption, and reducing suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

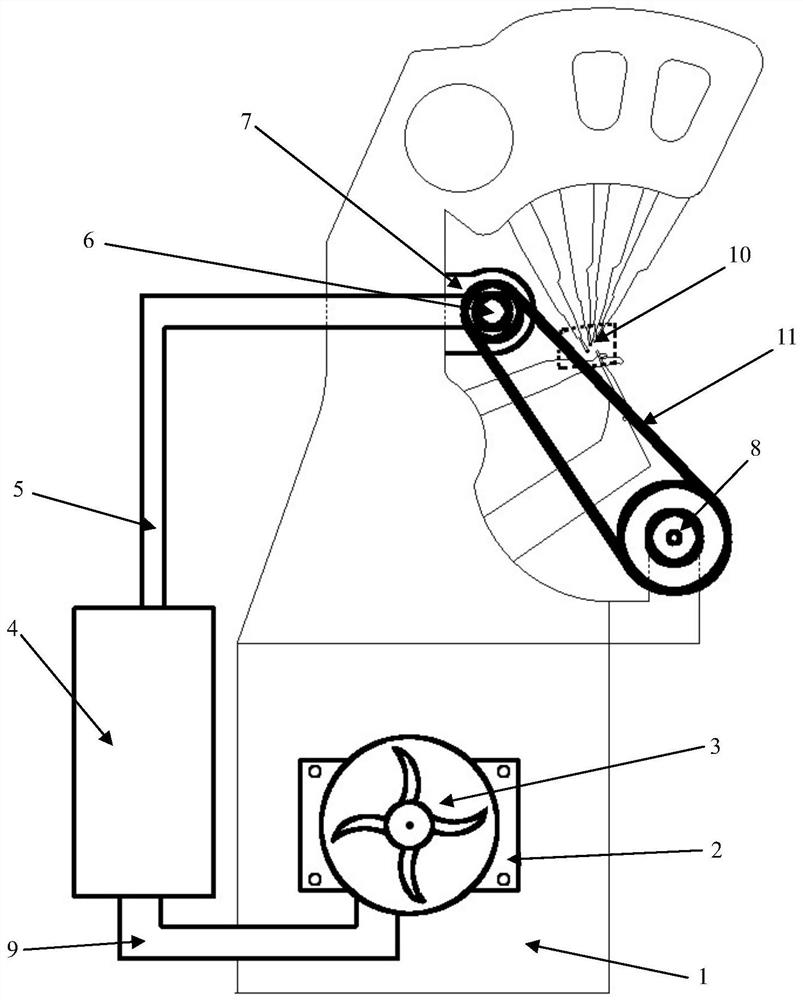

[0038] Such as Figure 1-3 As shown, the present embodiment provides a kind of dust removal system for warp knitting machine, which is installed near the warp knitting machine host 1 as a relatively independent system of the warp knitting machine host 1 (side or rear positions), and is fixed with the warp knitting machine host 1 Connected or installed separately, the warp knitting machine host 1 includes: a knitting area 10 .

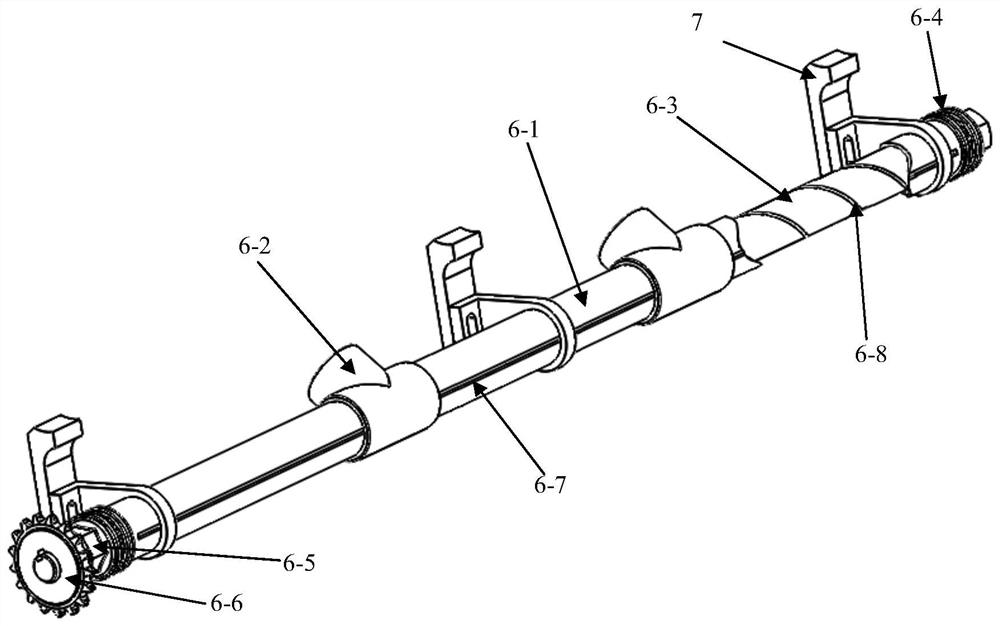

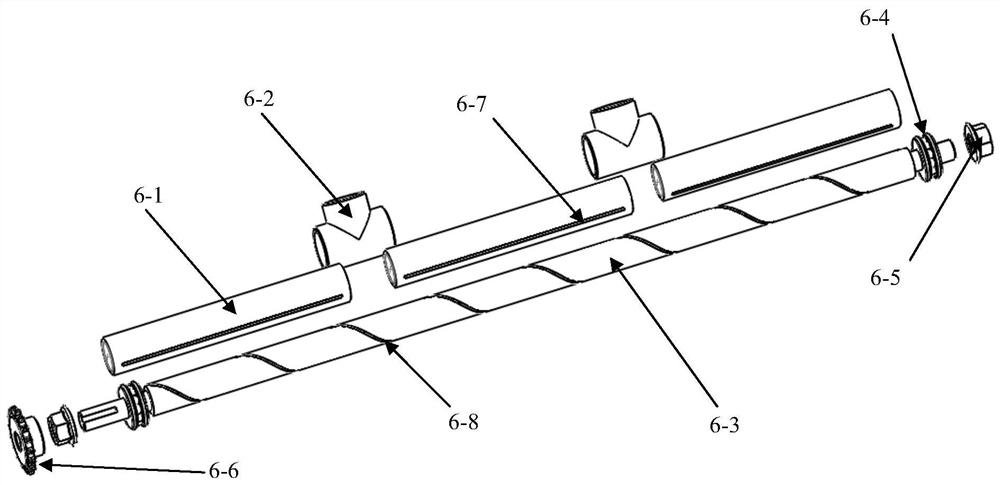

[0039] The dust removal system for warp knitting machines includes: suction fan base 2, suction fan 3, fly dust collection box 4, first air duct 5, movable tuyere device 6, tuyere fastener 7, and second air duct 9;

[0040] The suction fan 3 is fixedly installed on the suction fan base 2, the suction fan base 2 is arranged on the warp knitting machine host 1, and the suction fan 3 is connected with the flying dust collection box 4 through the second air pipe 9, The fly dust collection box 4 is connected with the mobile tuyere device 6 through the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com