Floor wireway slotting device

A wire pipe and floor technology, which is applied in the field of floor wire pipe slotting devices, can solve the problems of easy dust generation and low work efficiency, and achieve the effect of helping to cool down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

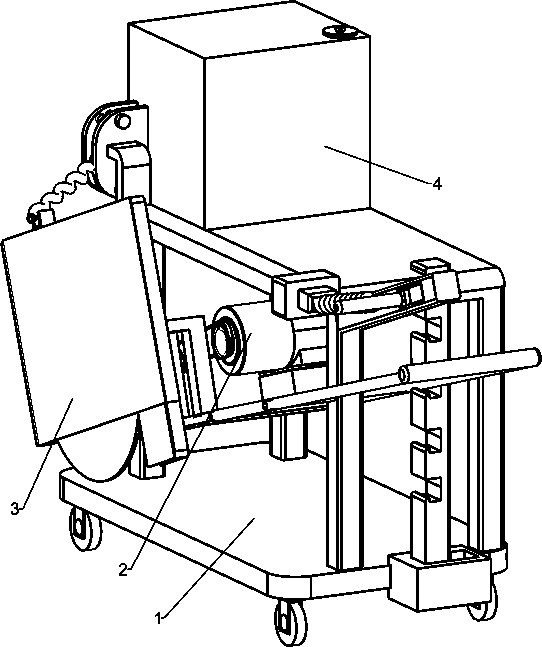

[0050] A kind of slotting device for electric wires and pipes on the floor, such as figure 1 As shown, a mounting device 1 and a cutting mechanism 2 are included, and the cutting mechanism 2 is connected to the mounting device 1 .

[0051] When a worker needs to make a groove on the floor wire duct, the worker first pushes the installation device 1 to drive the cutting mechanism 2 to move, so that the parts of the cutting mechanism 2 are aligned with the position where the groove needs to be made, and then the worker starts the cutting mechanism 2 to make the cutting mechanism 2 open. slot, while the worker pushes the installation device 1 to drive the cutting mechanism 2 to move, so that the parts of the cutting mechanism 2 are slotted while moving to open the floor wire and duct groove.

Embodiment 2

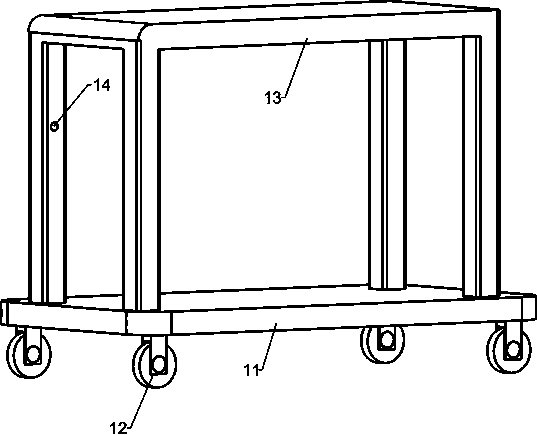

[0053] On the basis of Example 1, such as Figure 2-3 As shown, the installation device 1 includes an installation base plate 11, an installation wheel 12 and an installation frame 13, the four corners of the bottom of the installation base plate 11 are rotatably connected with the installation wheels 12, the top of the installation base plate 11 is provided with an installation frame 13, and the front side of the middle part of the installation frame 13 A fixing hole 14 is provided, and the parts of the cutting mechanism 2 are connected to the fixing hole 14 in a rotational manner.

[0054] When a worker needs to slot the wire duct on the floor, the worker first pushes the installation frame 13 so that the installation wheel 12 rotates to drive the cutting mechanism 2 to move, so that the parts of the cutting mechanism 2 are aligned with the position that needs to be slotted, and then the worker starts the cutting mechanism 2, Cutting mechanism 2 is slotted, and the workman p...

Embodiment 3

[0058] On the basis of Example 2, such as Figure 4-6 As shown, include dust-proof mechanism 3, dust-proof mechanism 3 also includes dust-proof rack 31, dust-proof block 32 and sliding block 35, fixed frame 21 left fronts are provided with two dust-proof blocks 32, two dust-proof blocks 32 front parts are provided with dust-proof frame 31, have through-hole 33 in the middle part of dust-proof frame 31 rear sides, cutting shaft 29 passes through-hole 33, cutting knife 26 is inside dust-proof frame 31, and dust-proof frame 31 tops have square Groove 34, sliding block 35 is connected with sliding on the square groove 34.

[0059] When the worker is cutting the ground groove, the dust-proof frame 31 makes the dust during cutting inside the dust-proof frame 31, and then leaks from the bottom of the dust-proof frame 31, which will not hinder the workman's sight and make the worker inhale the dust to affect his health.

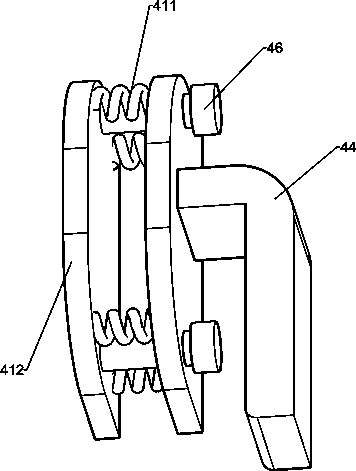

[0060] Also include sprinkler mechanism 4, sprinkler mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com