Flexible smart piezoelectric sensor based on pentacene organic field-effect transistor coupled with PVDF nanopillars

An intelligent piezoelectric and pentacene technology, which can be used in the manufacture of semiconductor devices, electro-solid devices, and semiconductor/solid-state devices, and can solve the problems of low piezoelectric strain constant and limited charge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

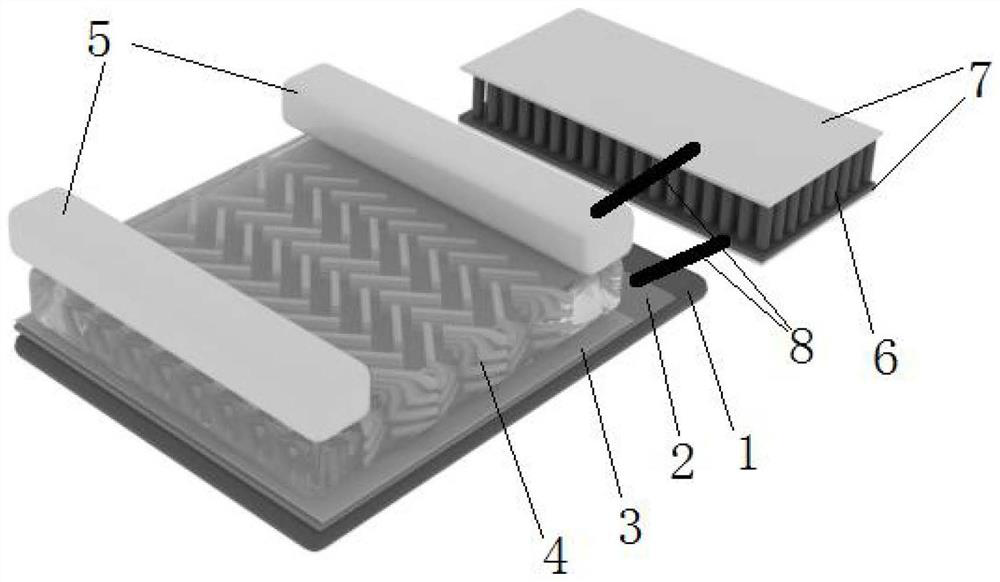

Embodiment 1

[0048] (1) Ultrapure water, acetone solution, and isopropanol were used to ultrasonically clean the experimental-grade PET film substrate for 10 minutes, and then the PET substrate was cleaned with an oxygen plasma cleaner for 10 minutes and dried in a nitrogen environment; the clean PET substrate was placed on the into the metal vacuum coater to the s -1 Deposit Al with a thickness of about 100nm as the bottom gate electrode; Next, configure a PMMA solution of 7mg / ml and use a spin coater to form a PMMA film of about 400nm on the aluminum electrode at a rate of 4000rpm as the dielectric layer of the device, and in a vacuum Treat in a drying oven at 60°C for 2 hours; then use an organic vacuum coater to the s -1 Deposit 40nm-thick organic small molecule material pentacene at a rate of 40nm to form an active layer to transport charges; then use a transmission electron microscope copper mesh (200um in length, 40um in width, and 20um in channel width) as a mask on the pentace...

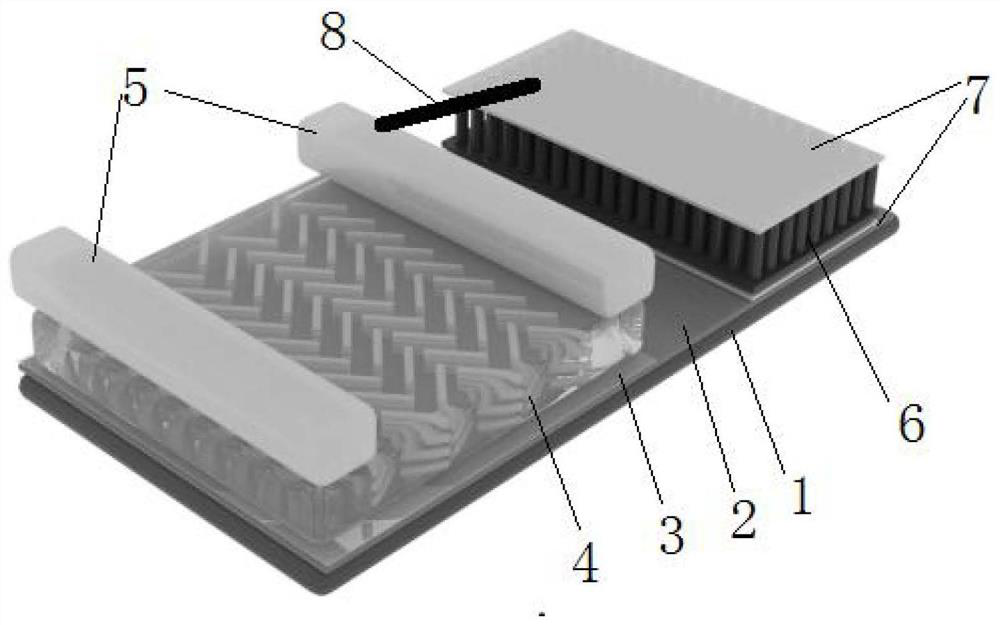

Embodiment 2

[0052] (1) Ultrapure water, acetone solution, and isopropanol were used to ultrasonically clean the experimental-grade PET film substrate for 10 minutes, and then the PET substrate was cleaned with an oxygen plasma cleaner for 10 minutes and dried in a nitrogen environment; the clean PET substrate was placed on the into the metal vacuum coater to the s -1 Deposit Al with a thickness of about 100nm as the bottom gate electrode; Next, configure a PMMA solution of 7mg / ml and use a spin coater to form a PMMA film of about 400nm on the aluminum electrode at a rate of 4000rpm as the dielectric layer of the device, and in a vacuum Treat in a drying oven at 60°C for 2 hours; then use an organic vacuum coater to the s -1 Deposit 40nm-thick organic small molecule material pentacene at a rate of 40nm to form an active layer to transport charges; then use a transmission electron microscope copper mesh (200um in length, 40um in width, and 20um in channel width) as a mask on the pentace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com