Flange plate detection device

A technology of detection device and limit device, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems such as the inability of flanges to fit each other, the damage of flanges, and the uneven surface of flanges. Achieve the effect of preventing incomplete fit and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

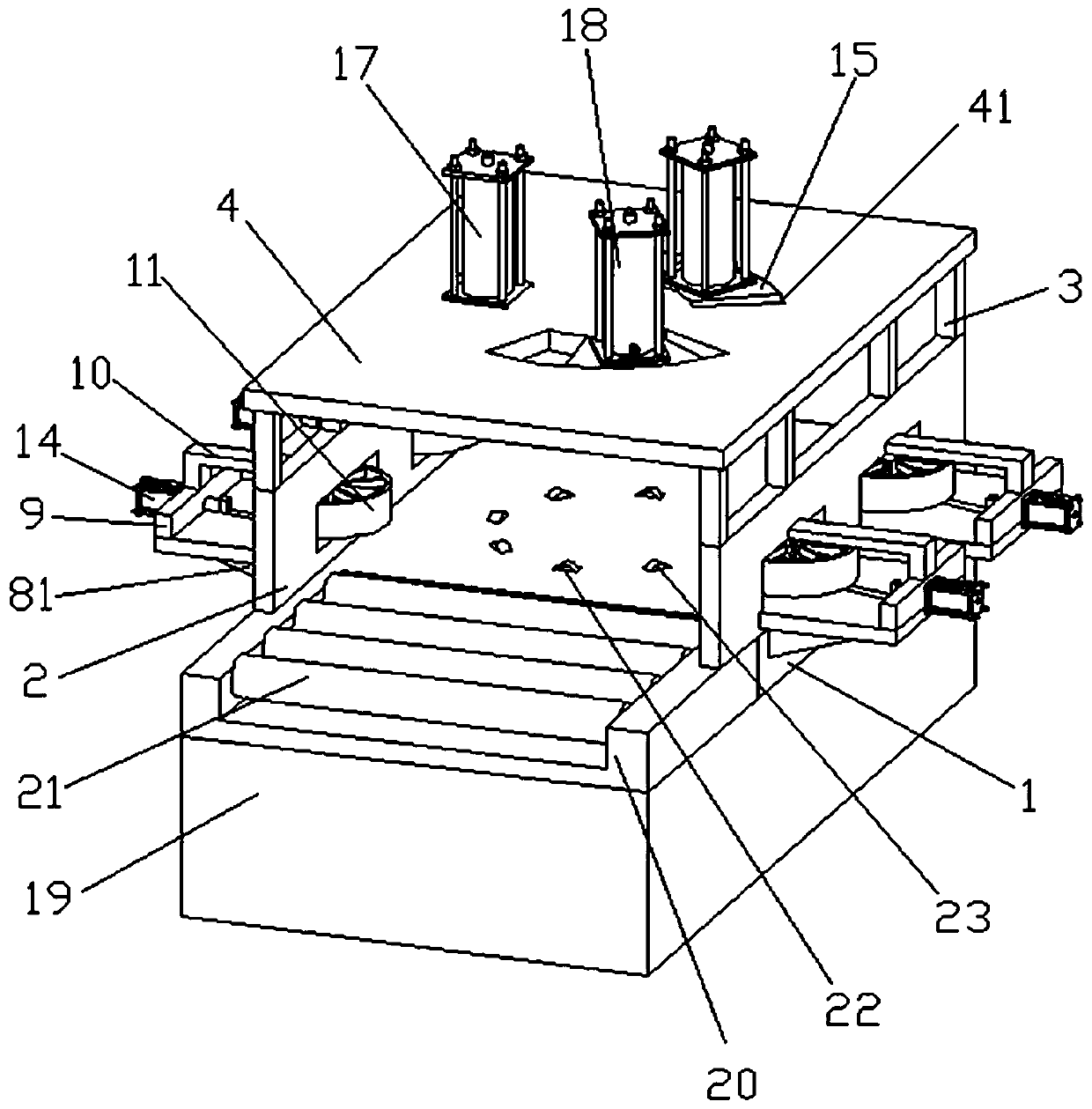

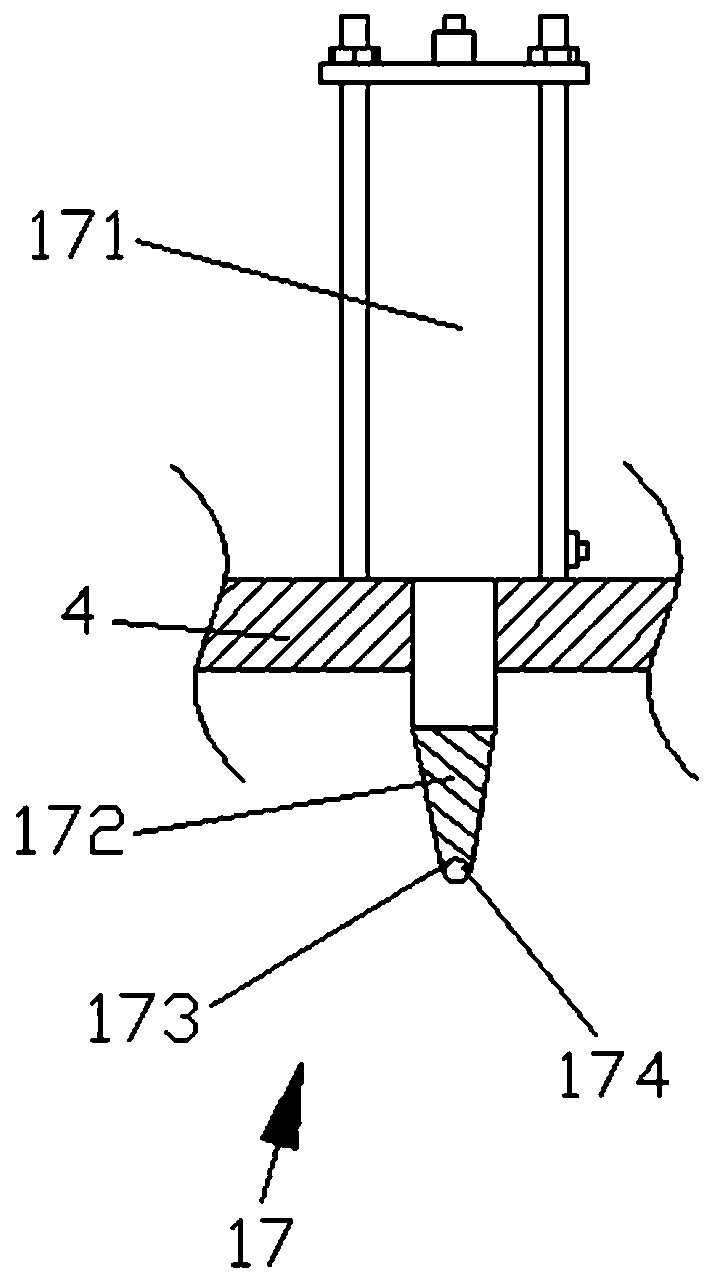

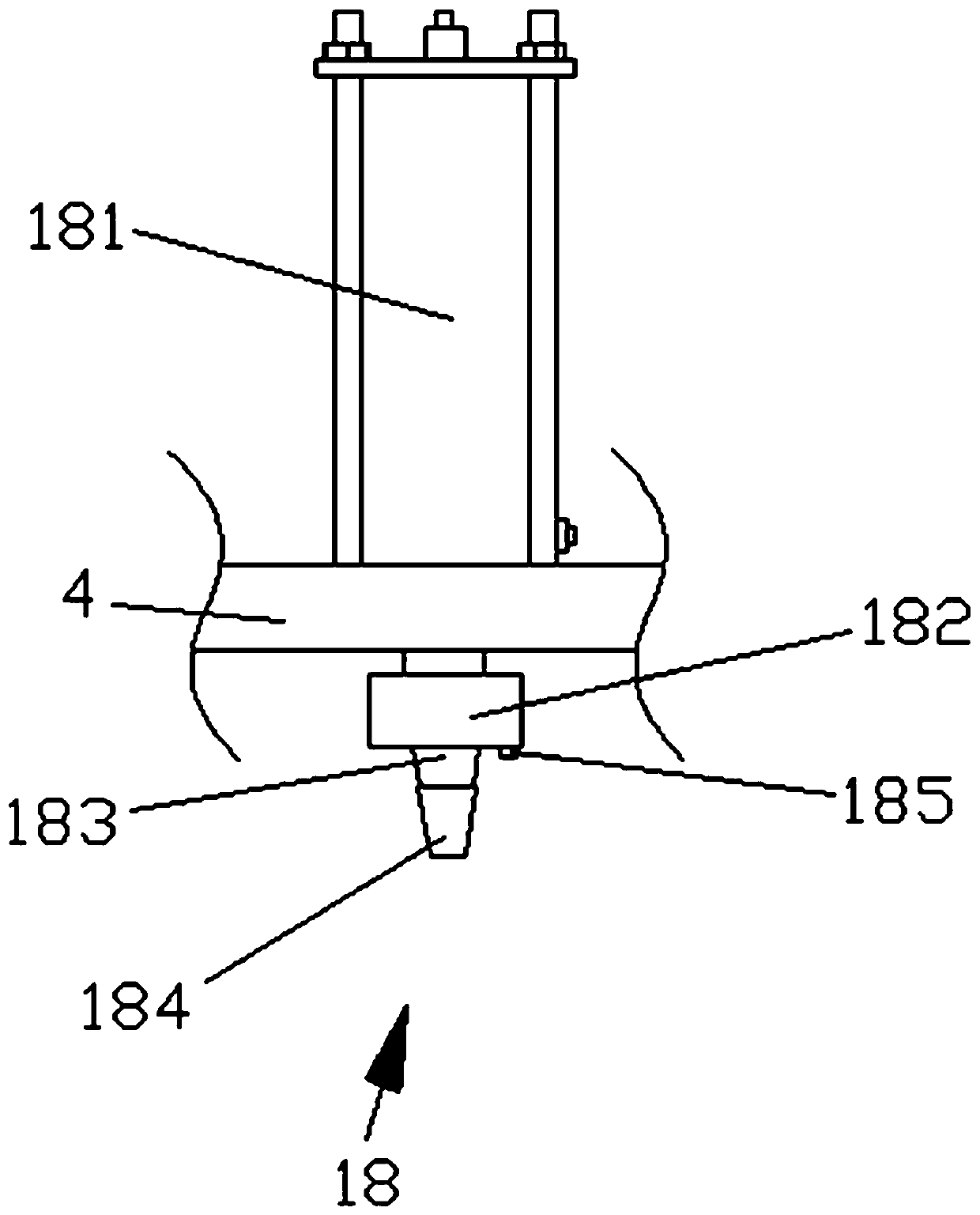

[0032] see figure 1 , figure 2 , image 3 , Figure 6 and Figure 7 Shown: a flange detection device, including a bottom plate 1, fixedly connected with two symmetrical fixed plates 2 on the upper side of the bottom plate 1, a top plate 4 is fixed on the fixed plate 2 through a group of connecting columns 3, and the A group of positioning devices 5 are installed on the top board 4 , and two limiting devices 6 are installed on each fixing board 2 .

[0033]The purpose of the present invention can be achieved through the following technical solutions: the fixed plate 2 is provided with two through holes 7, the through holes 7 are square and arranged symmetrically in pairs, the limiting device 6 is arranged inside the through holes 7, and the limiting device 6 includes a first support plate 8, the first support plate 8 is vertically inserted on the fixed plate 2, and the first support plate 8 is fixedly connected to the fixed plate 2 with bolts, and the first support plate 8...

Embodiment 2

[0043] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown: including the bottom plate 1, two symmetrically arranged fixed plates 2 are fixedly connected on the upper side of the bottom plate 1, and the top plate 4 is fixed on the fixed plate 2 through a group of connecting columns 3, and a set of positioning devices are installed on the top plate 4 5. Two limit devices 6 are installed on each fixed plate 2. There are two through holes 7 on the fixed plate 2. The through holes 7 are square and arranged symmetrically. The limit devices 6 are set in the through holes 7. Inside, the limiting device 6 includes a first support plate 8, the first support plate 8 is vertically plugged on the fixed plate 2, and the first support plate 8 is fixedly connected to the fixed plate 2 using bolts, and the first support plate 8 is connected to the fixed plate 2. One end of the second support plate 9 is fixed, the first support plate 8 and the second support plate 9 are verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com