Nodular cast iron pipe bell and spigot connection sealing element

A technology for ductile iron pipes and seals, which is applied in sleeve/socket connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as increased production costs, easy cracking of seals, and large compression ratio of seals. Achieve the effects of improving alignment accuracy, increasing service life, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

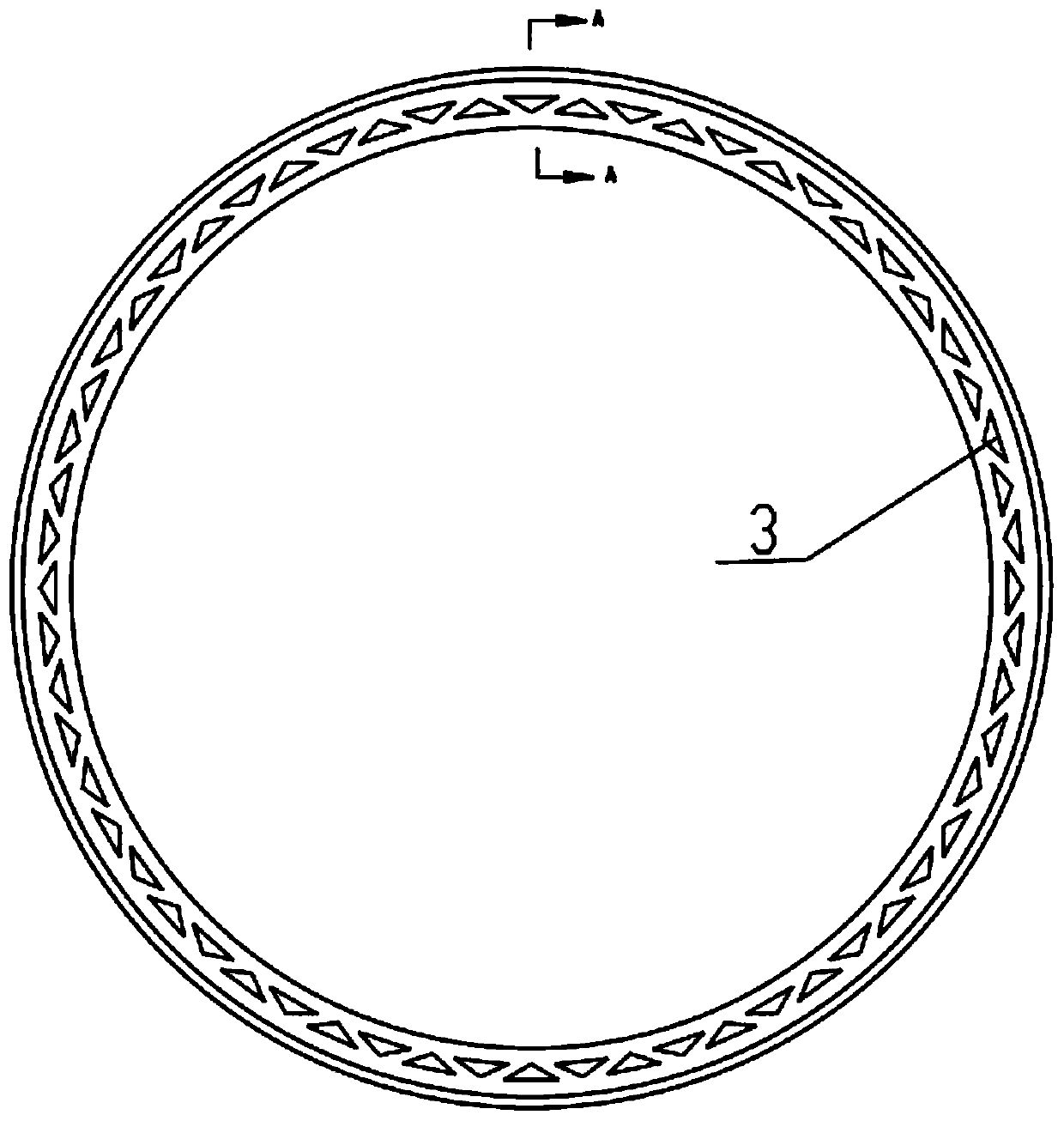

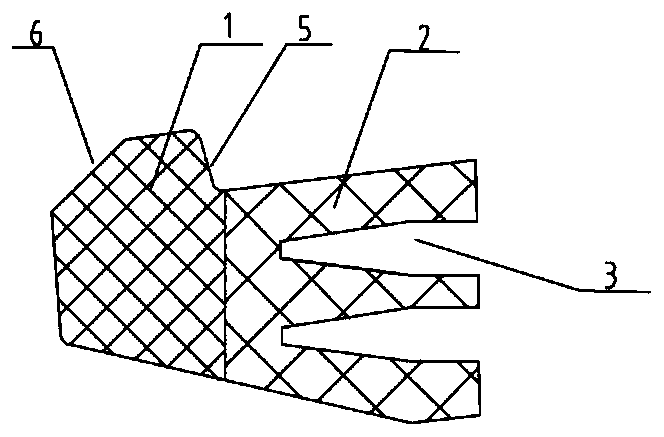

[0031] This embodiment selects DN400 specification ductile iron pipe, such as figure 2 , 4 As shown, the stress and strain relief holes are evenly arranged in an array with the circular center of the seal body as the center. A stress and strain relief hole is evenly arranged every 6 degrees. The shape of the stress and strain relief hole at the bottom surface of the gasket is an isosceles triangle with an obtuse angle of 120 degrees and an acute angle of 30 degrees. Two adjacent stress and strain relief holes are arranged symmetrically to form a spacer A continuous arrangement of ribbed structures. Such as Figure 5 As shown, during installation, the protrusion of the seal supporting body 1 is engaged with the groove of the rubber ring of the ball milled pipe socket 4, and the protrusion is provided with an anti-off surface 5 matching with the rubber ring groove of the ball milled pipe socket 4 And the thrust surface 6 that resists the medium pressure can effectively reduc...

specific Embodiment 2

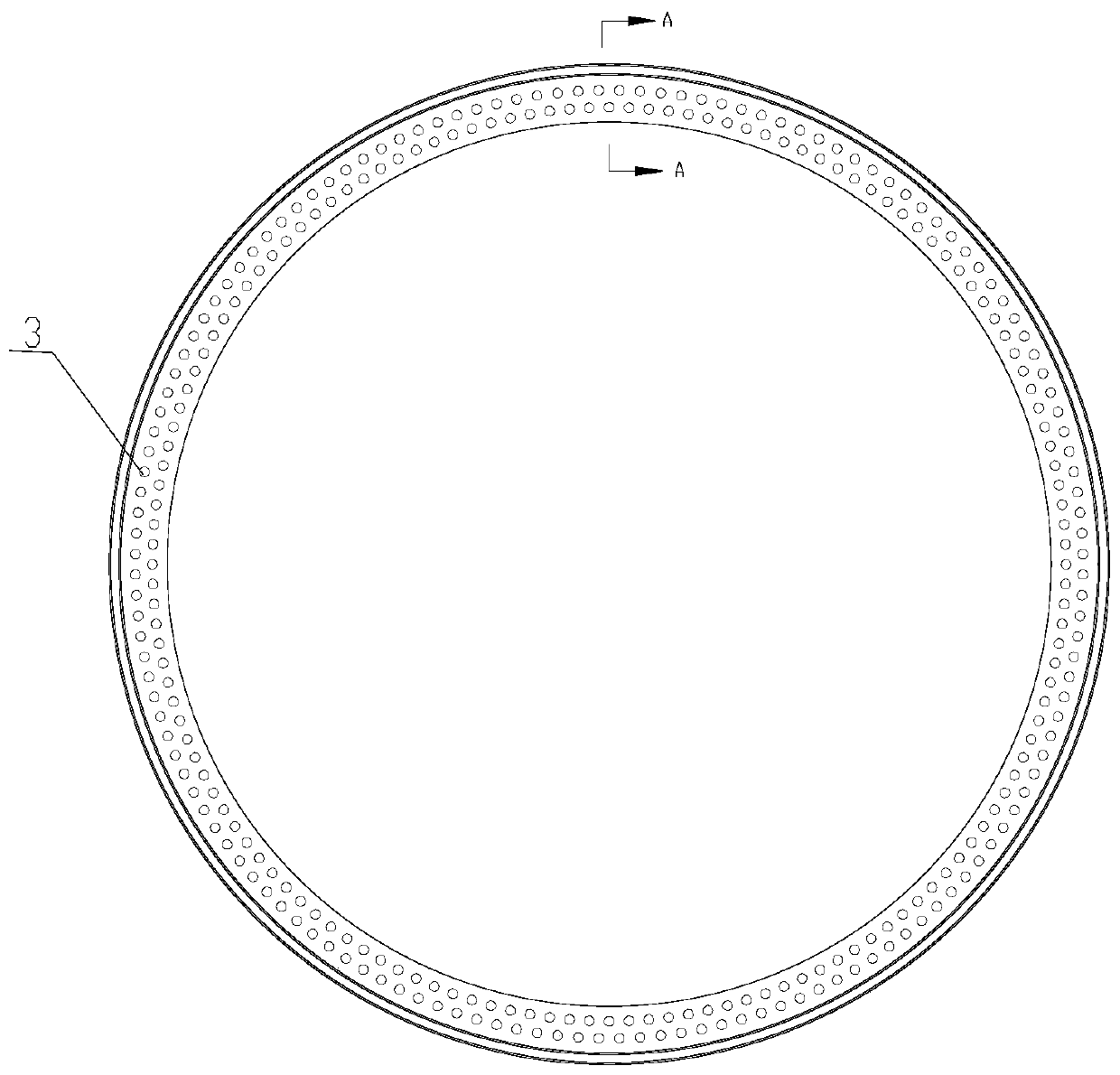

[0036] Such as figure 1 , 3 As shown, the stress and strain relief holes 3 on the contact surface between the seal and the pipeline supply medium are arranged in a circular double-row misalignment, and the stress and strain relief holes 3 take the circular center of the seal as the center and form a plane divergent arrangement along the direction of the seal; That is, there are two rows of stress and strain relief holes, and the inner ring and the outer ring are misplaced. Each row of stress and strain relief holes takes the center of the seal body as the center, and a stress and strain relief hole is set every 2.5 degrees on the seal. A misalignment of 1.25 degrees is set between the front and rear rows. The stress relief hole 3 is provided in two sections inside the sealing member, the side close to the outer surface of the sealing member is a cylinder, and the side away from the outer surface of the sealing member is a cone. When the socket 7 of the ball milling pipe is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com