A method for exploiting natural gas hydrate by steam injection

A technology of natural gas and hydrate, which is applied in the fields of mining fluid, coal gasification, earth drilling and mining, etc. It can solve the problems that the seabed combustible ice cannot be put into large-scale commercial mining, the risk of sand production, and reservoir damage, etc., so as to improve the development efficiency Low, improve the steam injection rate, increase the effect of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

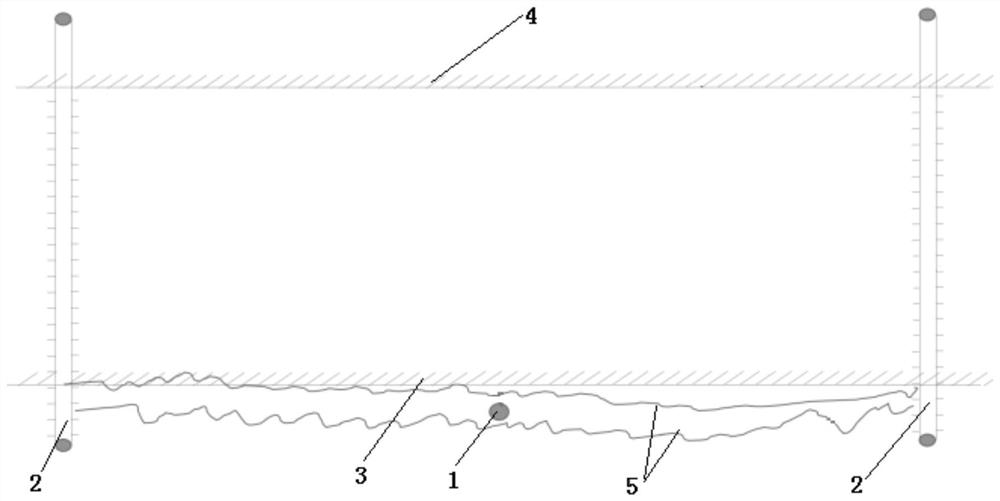

[0045] This embodiment provides a preferred method for producing natural gas hydrate by steam injection.

[0046] Introduction to reservoir properties:

[0047] The burial depth of the simulated reservoir I is 330m, the effective thickness of the reservoir is 50.0m, and the net-to-total thickness ratio is 0.92. The reservoir is loose sandstone, which is cemented by hydrate crystallization. There is no pure mudstone interlayer inside the reservoir, and the upper part of the reservoir has a good caprock; there is a coarse sandstone layer at the bottom, the permeability is above 10 Darcy, and the formation pressure is 3.3MPa.

[0048] The production process of the method of steam injection to exploit natural gas hydrate is:

[0049] 1) According to the geological characteristics of the reservoir and the current development status, make a preliminary evaluation:

[0050] The reservoir meets the following conditions: the shallow reservoir is 330m, the reservoir thickness is >20.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com