Auxiliary frame body with high safety performance for installation of light-transmitting panels in energy-saving buildings

A technology of safety performance and light-transmitting panels, which is applied in the field of auxiliary frames, can solve problems such as operator slipping, weak functionality, and inability to achieve rapid adjustment, improve protection capabilities, and improve anti-skid capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

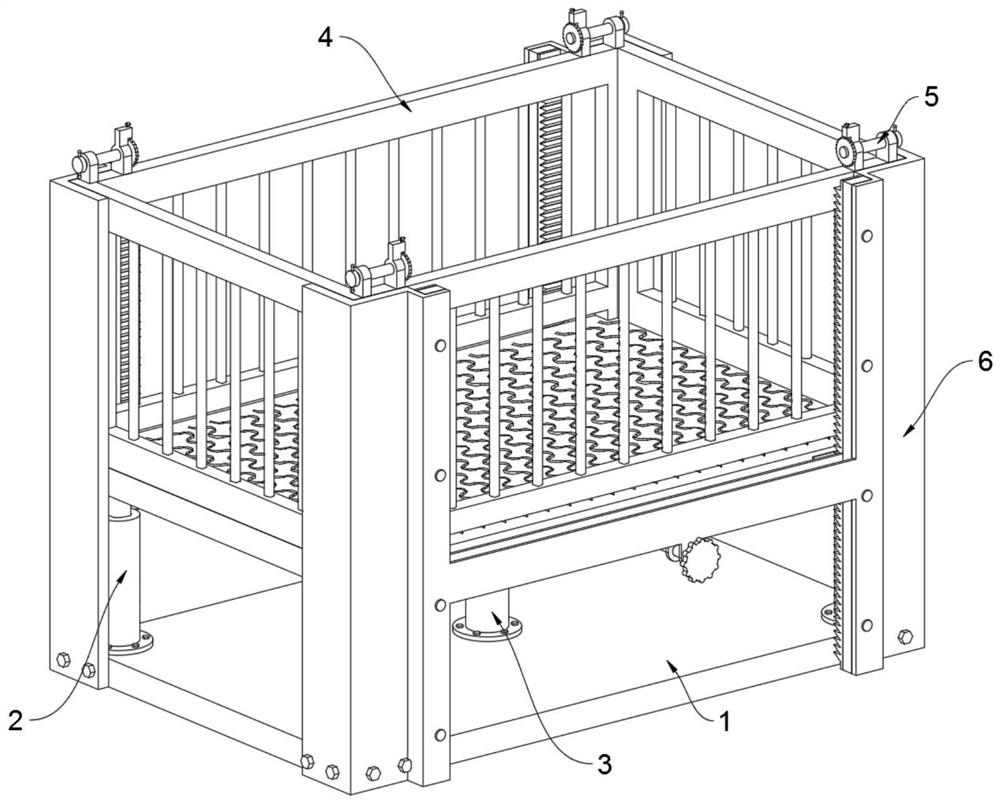

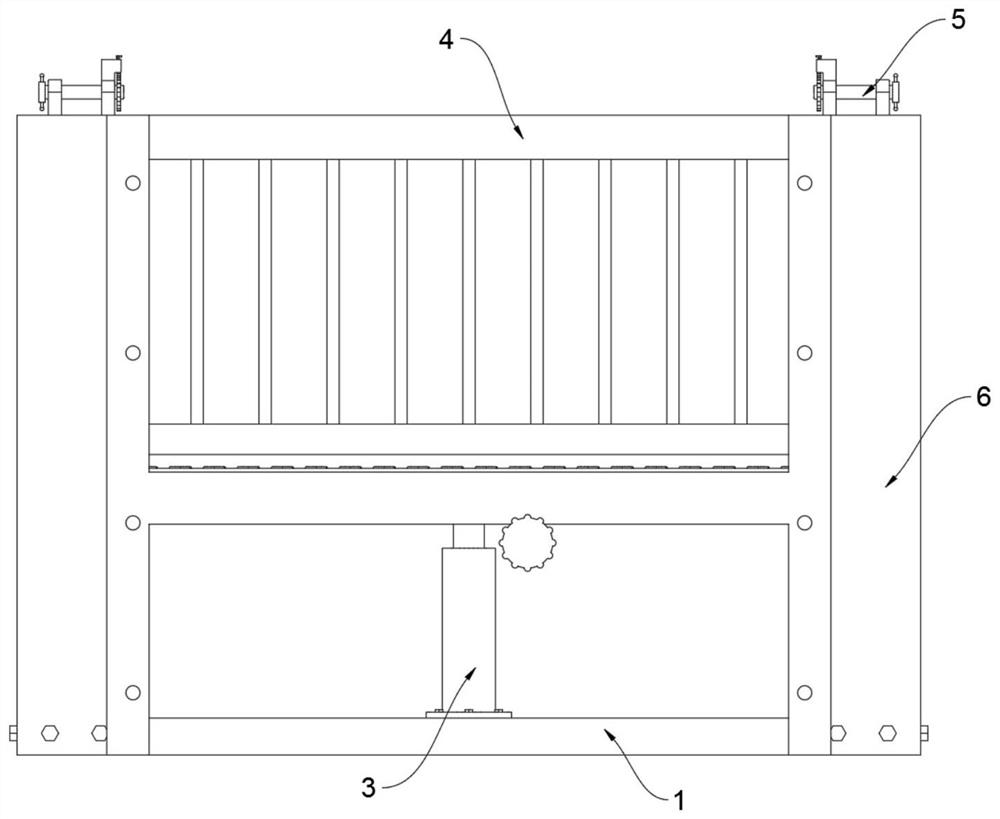

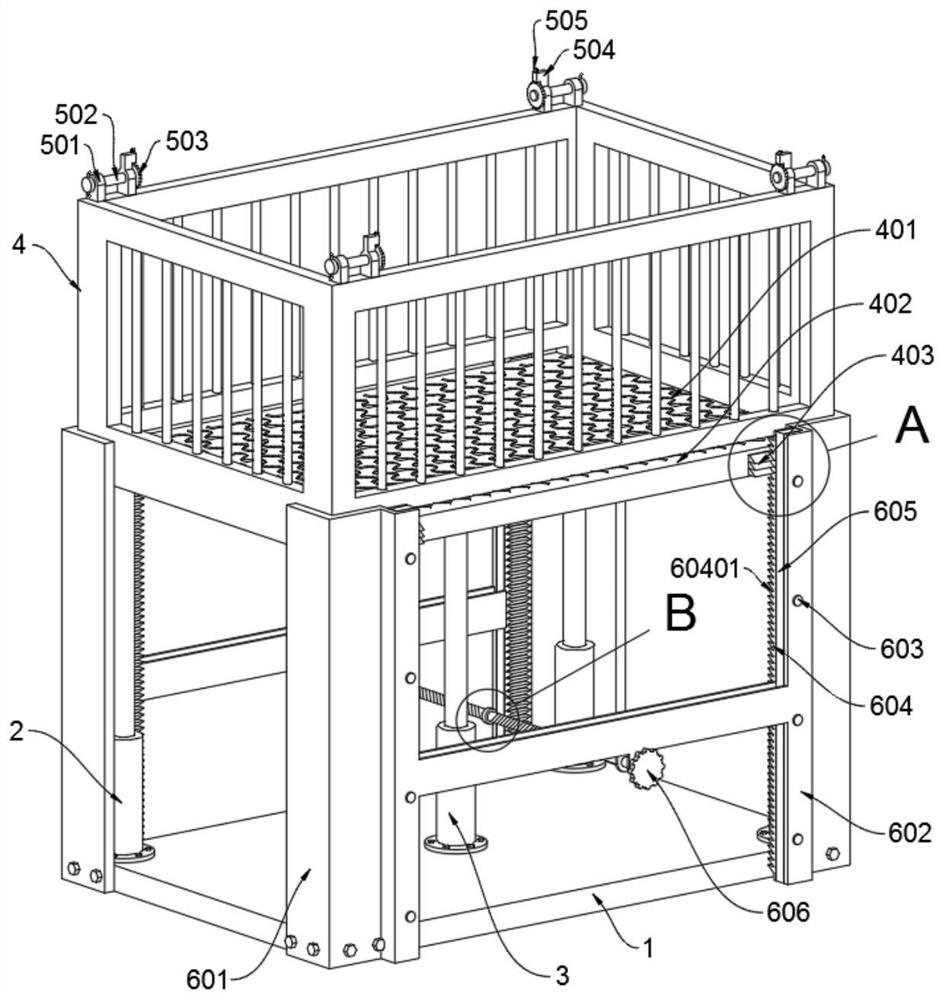

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides an auxiliary frame body with high safety performance for the installation of energy-saving building light-transmitting panels, including a base 1; the four corners of the top surface of the base 1 are fixedly connected with a sliding telescopic rod 2 by bolts, and the top surface of the base 1 The central position is fixedly connected with a hydraulic telescopic rod 3 by bolts; the top surfaces of the sliding telescopic rod 2 and the hydraulic telescopic rod 3 are fixedly connected with the bottom surface of the frame body 4, and the top four corners of the frame body 4 are all provided with a rope adjustment Structure 5; the outer side of the base 1 is fixedly connected with a protective structure 6 by bolts; refer to image 3 and Figure 4 , the protective structure 6 also includes a protective seat 602, a sliding rod 603, a clamping seat 604, a tooth row 60401 and an elastic member 605, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com