Damping method and damping device based on tension-torsion coupling effect

A technology of coupling effect and shock absorption device, applied in the field of mechanical shock absorption, can solve the problems of difficult maintenance, poor shock absorption effect, and difficult maintenance of hydraulic buffer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

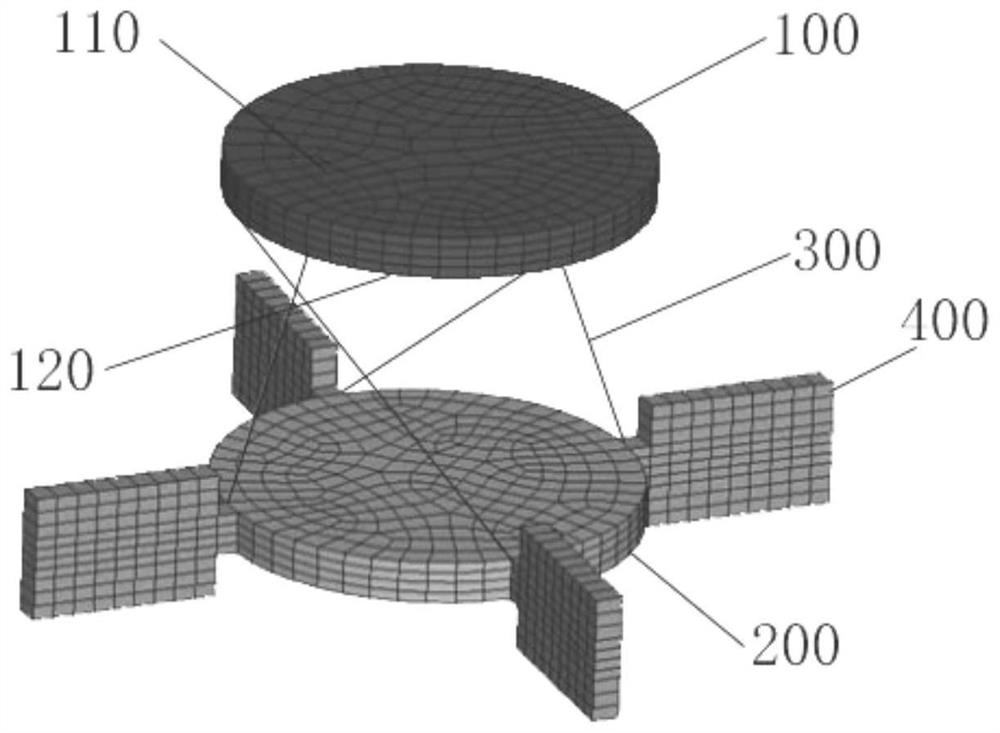

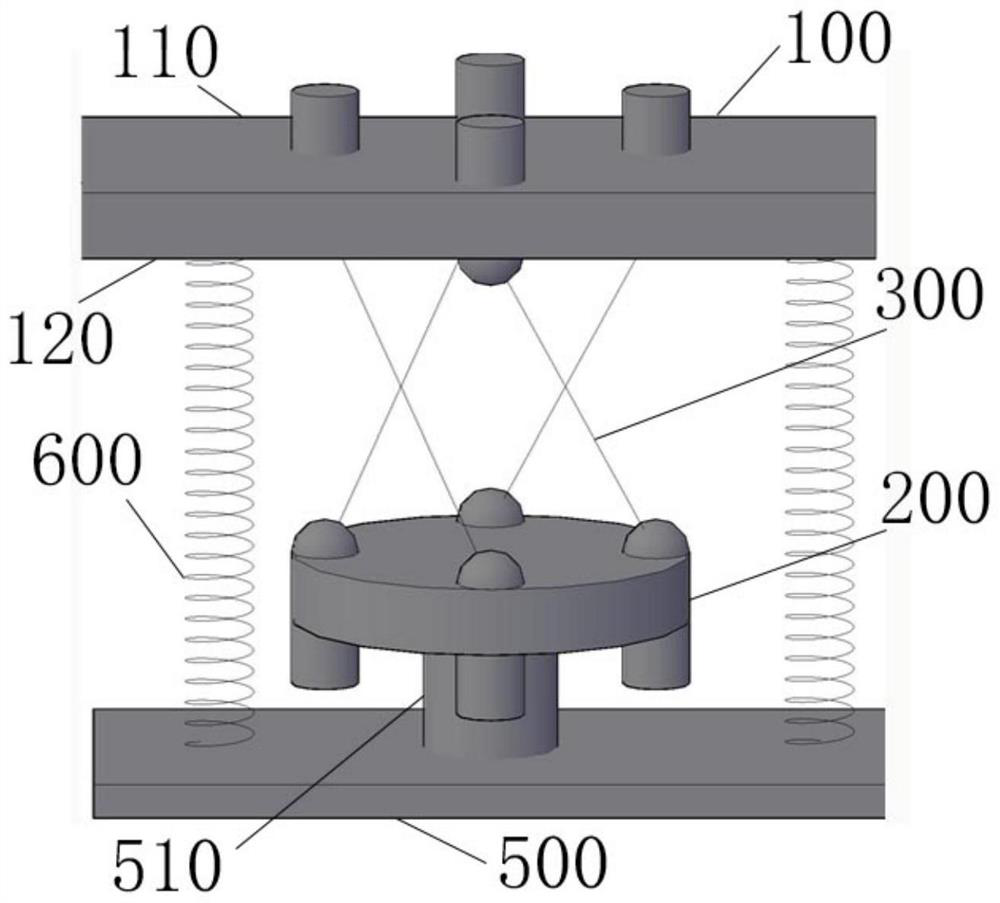

[0058] Such as figure 1 and Figure 4 As shown, this embodiment discloses a damping method based on the tension-torsion coupling effect, and the method includes

[0059] When the upper side 110 of the first end plate 100 is impacted, the first end plate 100 is moved toward the turntable 200 to shorten the distance between the first end plate 100 and the turntable 200;

[0060] When the distance between the first end plate 100 and the turntable 200 is shortened, the first end plate 100 drives the turntable 200 to rotate through the transmission of the transmission rod 300, and at the same time the elastic member 600 is compressed;

[0061] The damping fluid passing through the filling chamber prevents the rotation of the turntable 200;

[0062] After the impact is over, the elastic potential energy stored in the elastic mechanism 600 is released to restore the first end plate 100 and the turntable 200 to their original positions, and at the same time, the damping fluid fillin...

Embodiment 2

[0071] Such as figure 1 and image 3 As shown, this embodiment discloses a shock absorbing device based on the tension-torsion coupling effect, which is used to perform work on the damping fluid through viscous resistance when the bridge is subjected to an external impact, so as to convert the impact potential energy into the kinetic energy of the turntable and then into The internal energy of the damping fluid liquid, including

[0072] The filling chamber, the first end plate 100, the turntable 200, the elastic member 600 and at least two transmission rods 300;

[0073] The filling chamber is filled with damping fluid, and the damping fluid is used to limit the rotation of the turntable 200;

[0074] The first end plate 100 includes an upper side 110 and a lower side 120, the upper side 110 is a force-bearing surface, the lower side 120 faces the turntable 200, and the first end plate 100 can only move toward the direction of the turntable 200;

[0075] The turntable 200 ...

Embodiment 3

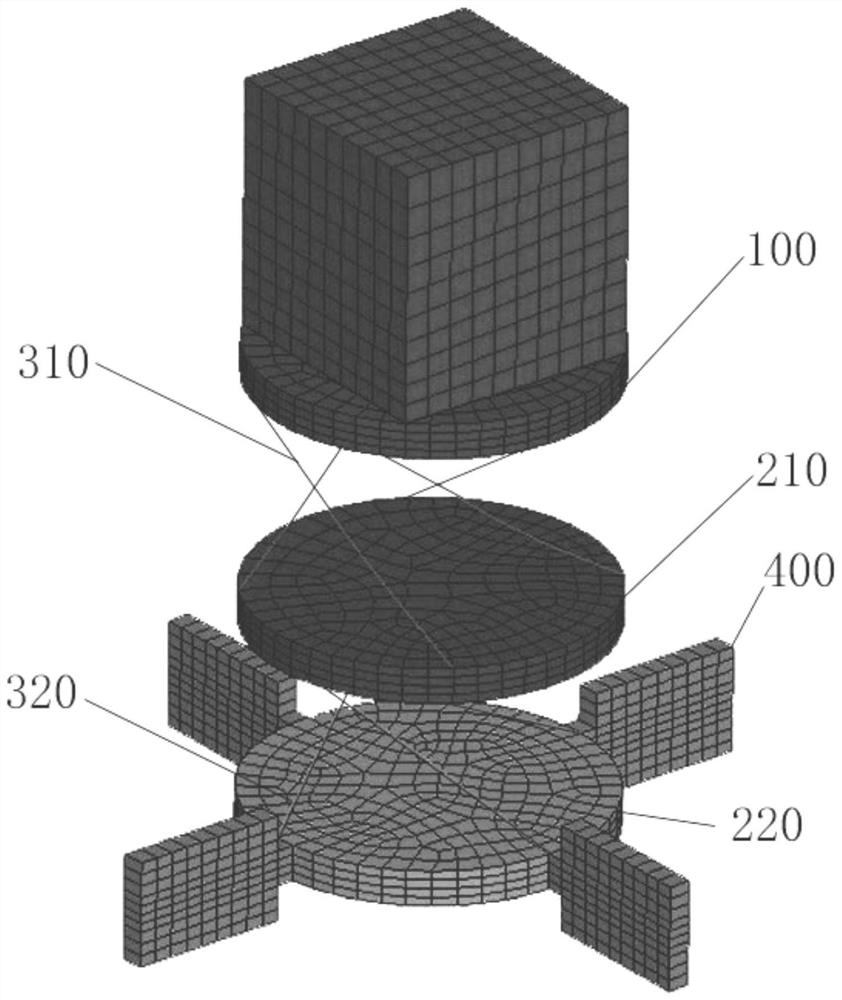

[0094] Such as figure 1 and figure 2 As shown, this embodiment discloses a shock absorber based on the tension-torsion coupling effect, including

[0095] At least one further turntable 200 is included;

[0096] The lower surface of the turntable 200 faces the upper surface of another turntable 200, and the other turntable 200 is arranged in the filling chamber;

[0097] The number of the transmission rods 300 is at least 4, and at least 2 transmission rods 300 are placed obliquely between the turntable 200 and another turntable 200, and one end of the transmission rod 300 is rotationally connected with the lower surface of the turntable 200, and the other end is connected with the lower surface of the turntable 200. The upper surface of the other turntable 200 is rotatably connected.

[0098] In the case of higher buffer requirements, the shock absorbing device also includes another turntable 200, the other turntable 200 is under the original turntable 200, and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com