Rapid carding equipment for textile fabrics

A textile fabric, fast technology, applied in textile and papermaking, fabric surface trimming and other directions, can solve the problems of textile pattern damage, pilling, etc., to achieve the effect of fast carding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

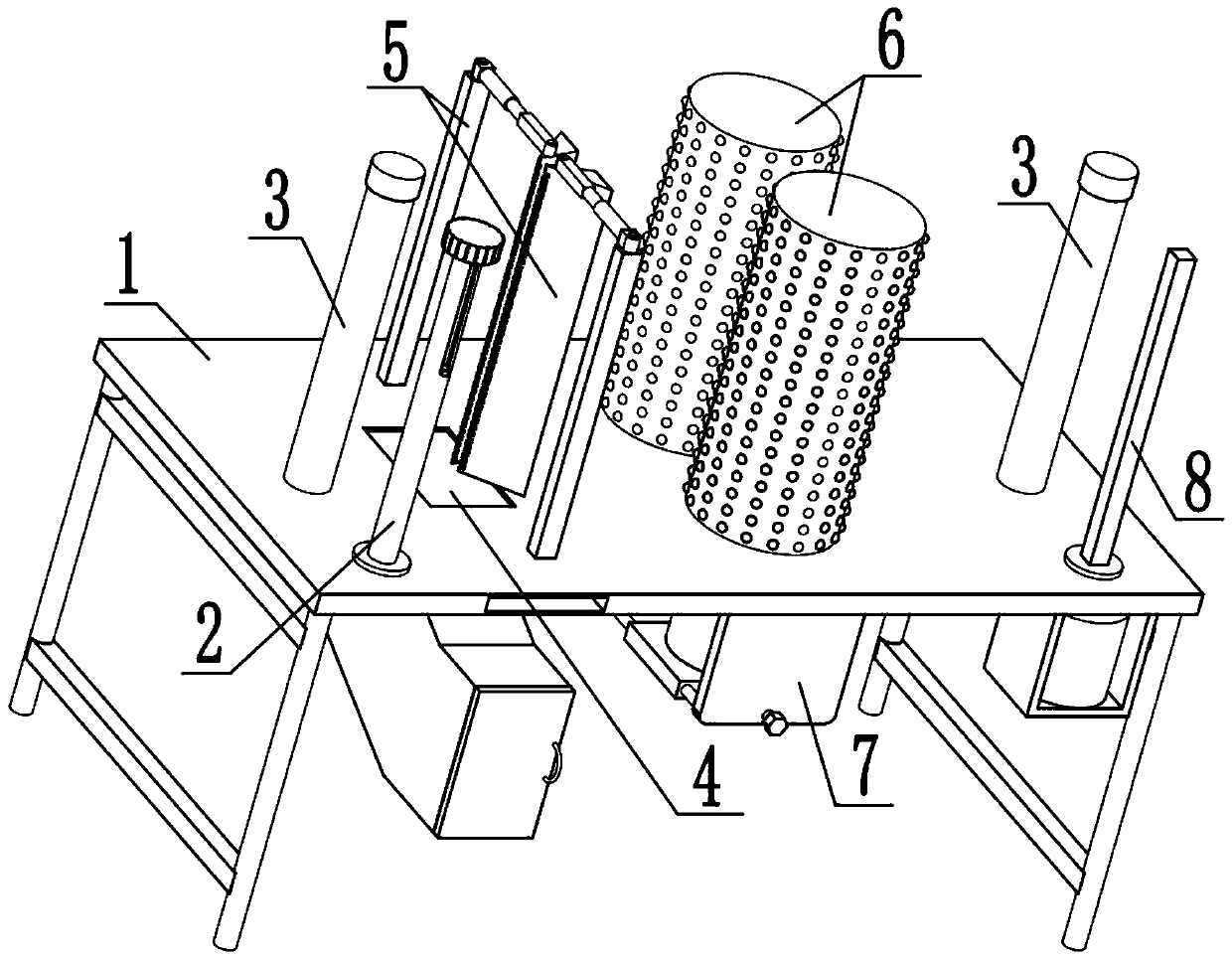

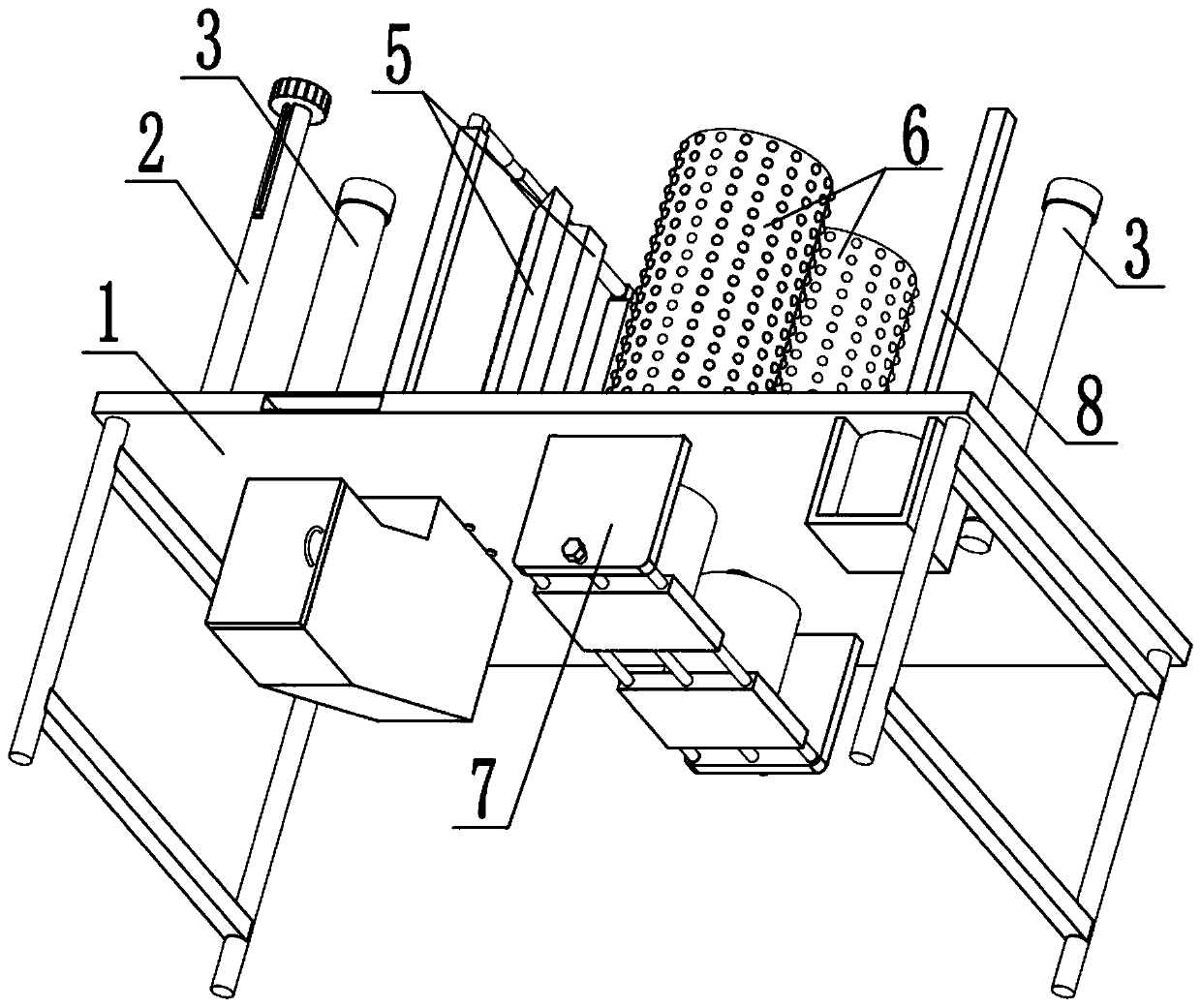

[0032] Combine below Figure 1-14Describe this embodiment, the present invention relates to the technical field of textile fabric carding, more specifically a kind of textile fabric rapid carding equipment, including carding bearing table 1, passive roller member 2, guide ironing member 3, telescopic switch device 4, Contact the shaving and carding device 5, the extrusion carding device 6, the spacing adjustment support device 7 and the active winding collection device 8, place the roll-on textile fabric on the vertical cavity 2-3, and then wind the textile fabric to another On the collection roller, the collection roller is slidably connected to the plug-in square column 8-4, and the starting motor II8-2 will drive the collection roller to rotate, thereby winding and collecting the textile fabric. When the textile fabric is collected, two scrapers are used to Board 5-1 disposes of the hair balls on the textile fabrics, and the hair balls will fall into the burr outlet 1-3 and...

specific Embodiment approach 2

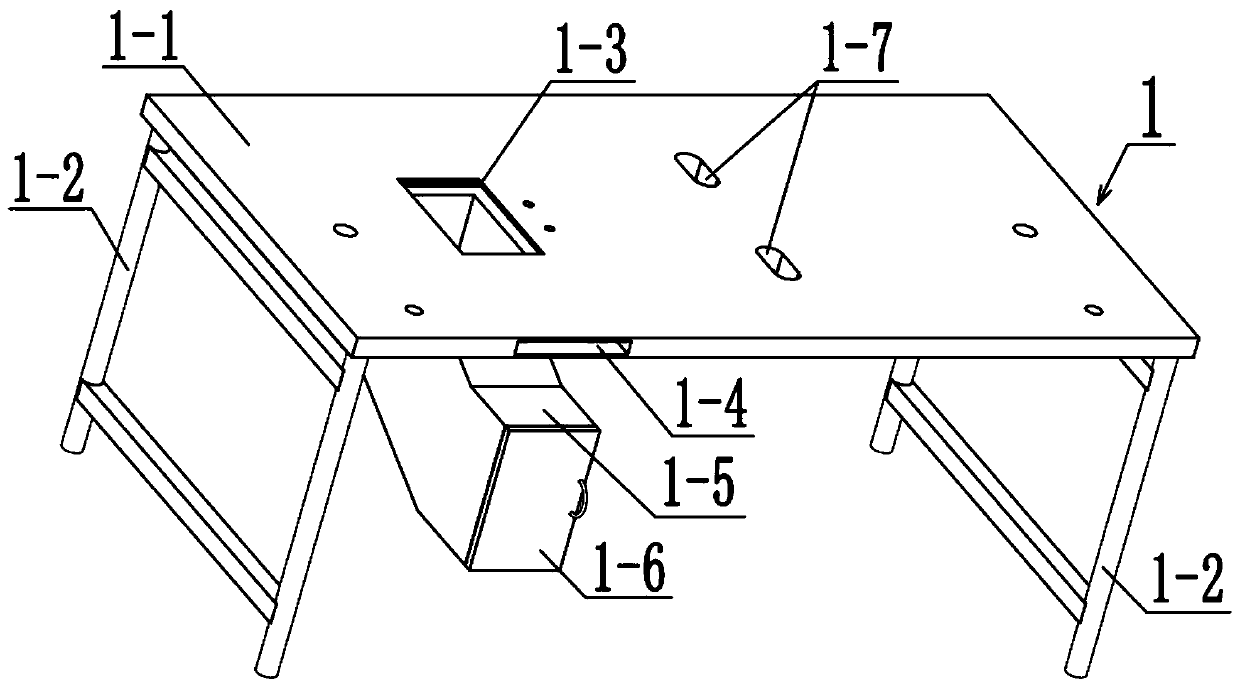

[0035] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain Embodiment 1. The carding carrying table 1 includes a supporting table 1-1, supporting legs 1-2, burr leakage 1-3, connecting slide 1-4, garbage Box 1-5, blocking door panel 1-6 and limit sliding opening 1-7, supporting table 1-1 plays the role of bearing connection, providing a fixed space for the whole device, supporting the left and right sides under the table 1-1 Both ends are fixedly connected with support legs 1-2, and the two support legs 1-2 play the role of support and fixation. The processed hair balls fall into the dustbin 1-5 through the hair leakage port 1-3, and the connection sliding port 1-4 can provide a connection space for the telescopic switch device 4, and the hair leakage port 1-3 and the connection sliding port 1-4 Connected, there is a dustbin 1-5 fixedly connected to the bottom of the leakage burr opening 1-3, and the dustbin 1-5 is used to collect hair ba...

specific Embodiment approach 3

[0037] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the second embodiment, the passive roller member 2 includes a connecting shaft I2-1, a connecting circular plate 2-2, a vertical bearing cavity 2-3, a handle 2-4, Connecting bolt 2-5, linkage shaft 2-6 and extrusion ring 2-7, connecting shaft I2-1 is rotatably connected to the rear of the left end of supporting platform 1-1, and connecting shaft I2-1 can be connected to circular plate 2-2 The axis of rotation is provided, and the top of the connecting shaft I2-1 is fixedly connected with a connecting circular plate 2-2. The connecting circular plate 2-2 can provide a fixed space for the bearing vertical cavity 2-3, and the connecting circular plate 2-2 and the bearing The table top 1-1 is in contact, and the upper part of the connecting circular plate 2-2 is fixedly connected with a load-bearing vertical cavity 2-3, which can slide and connect roll-on textile fabrics to the load-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com