Ultra-thin AGV differential driving device

A differential drive, ultra-thin technology, applied in the direction of power devices, electric power devices, control devices, etc., can solve the problems of unable to increase the size of the drive motor, the overall power of the machine, the limited overall height, and the limited overall height. Achieve the effect of flattening and miniaturization, facilitate miniaturization, and reduce the risk of cable damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

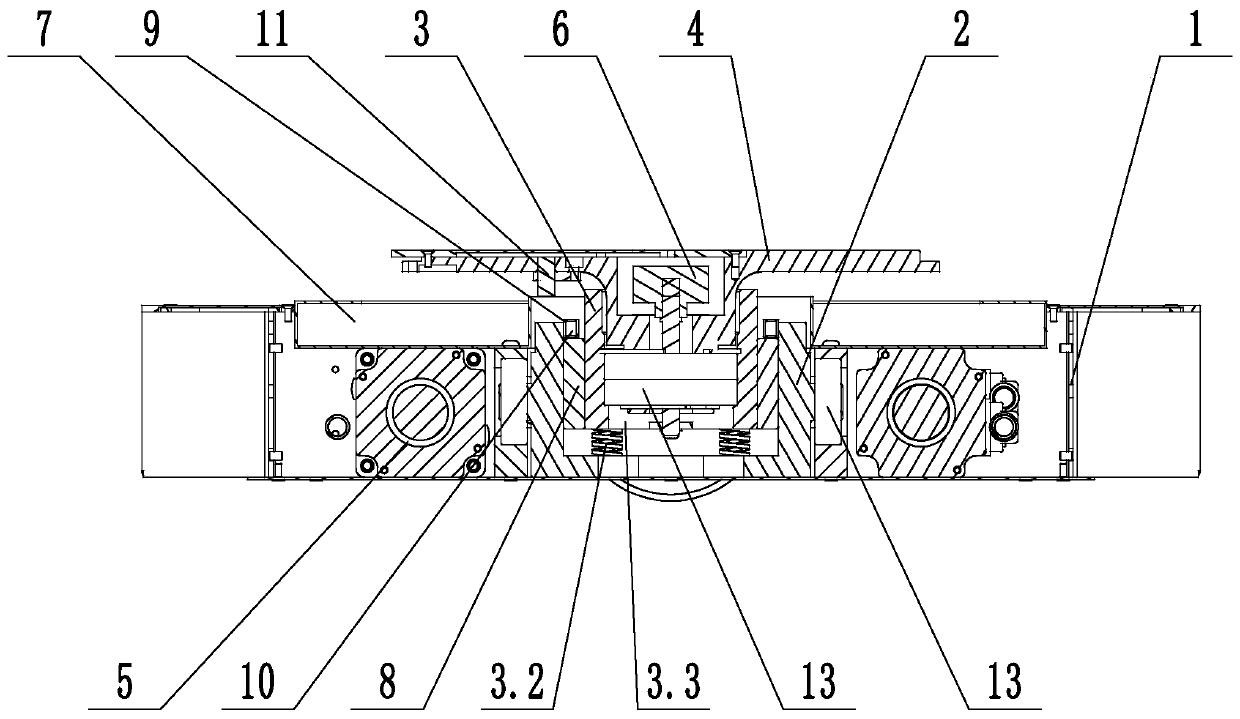

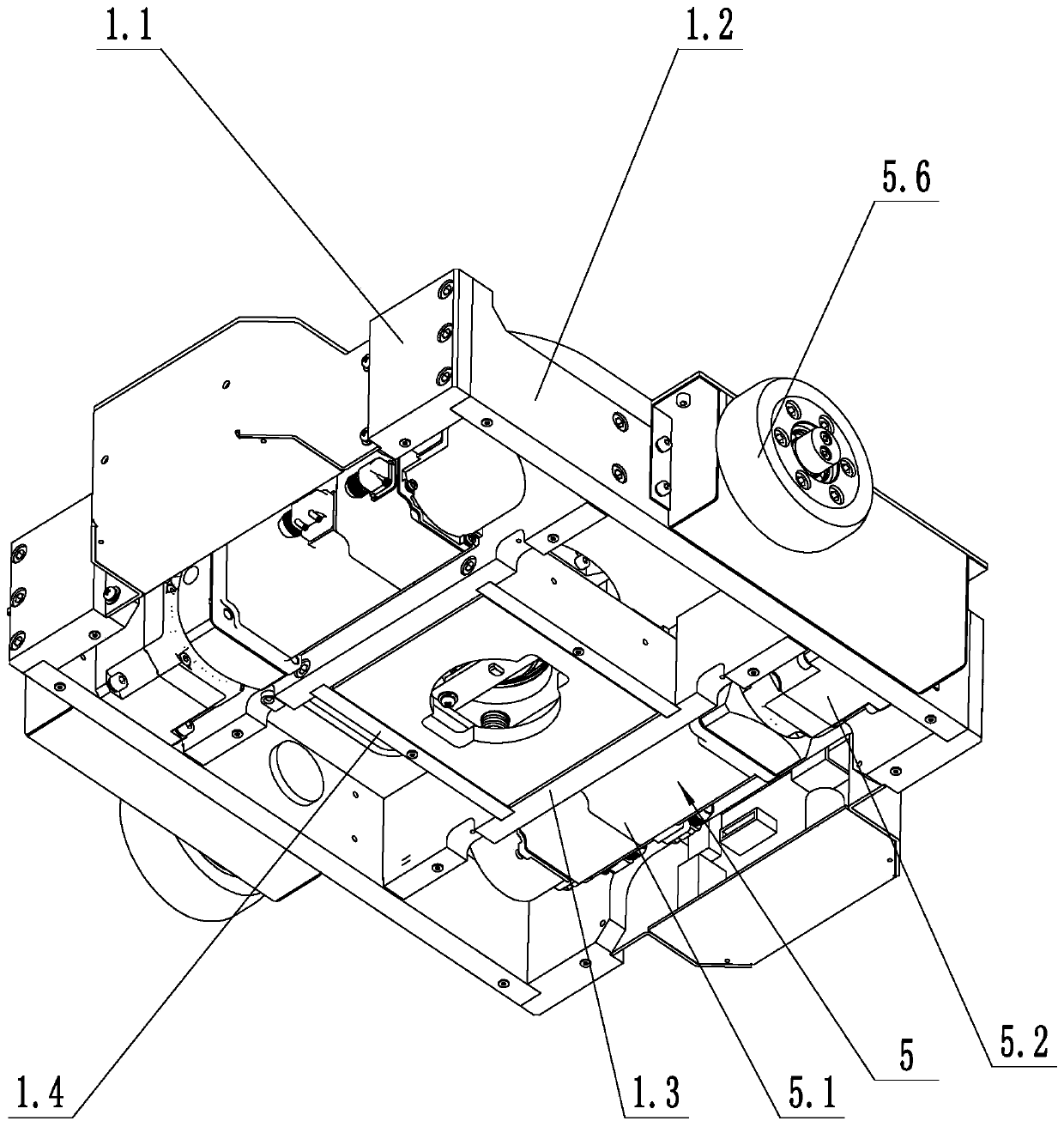

[0031] Such as figure 1 , figure 2 and image 3 As shown, an ultra-thin AGV differential drive device includes a base 1, a rocking base 2, a spring seat 3, a rotary disc shaft 4 and a harness storage box 7; figure 2 As shown, the base 1 includes the shell mounting seat 1.1, the mounting plate 1.2, the splint 1.3 and the rib 1.4, the shell mounting seat 1.1, the mounting plate 1.2 and the splint 1.3 have a "mesh" structure, and the splint 1.3 and the rib 1.4 are "well" word structure. The base 1 is provided with two driving mechanisms 5 for driving the base 1 to move, and the two driving devices are arranged on opposite sides of the base 1 . Such as image 3 and Figure 5 As shown, the driving mechanism 5 includes a driving motor 5.1, a reducer 5.2, a driving gear 5.3, an intermediate gear 5.4, a driven gear 5.5, and a driving wheel 5.6, and the driving gear 5.3, the intermediate gear 5.4, and the driven gear 5.5 are sequentially meshed with the base The side wall of 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com