Mud removing feeding machine

A feeding machine and feeding technology, which is applied in the field of mining machinery, can solve problems such as abnormal high efficiency, affecting the quality of finished materials, and accumulation of mineral materials on the feeding and conveying surface, so as to improve the excitation effect and efficiency, and the screening effect is ideal , The effect of material screening is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

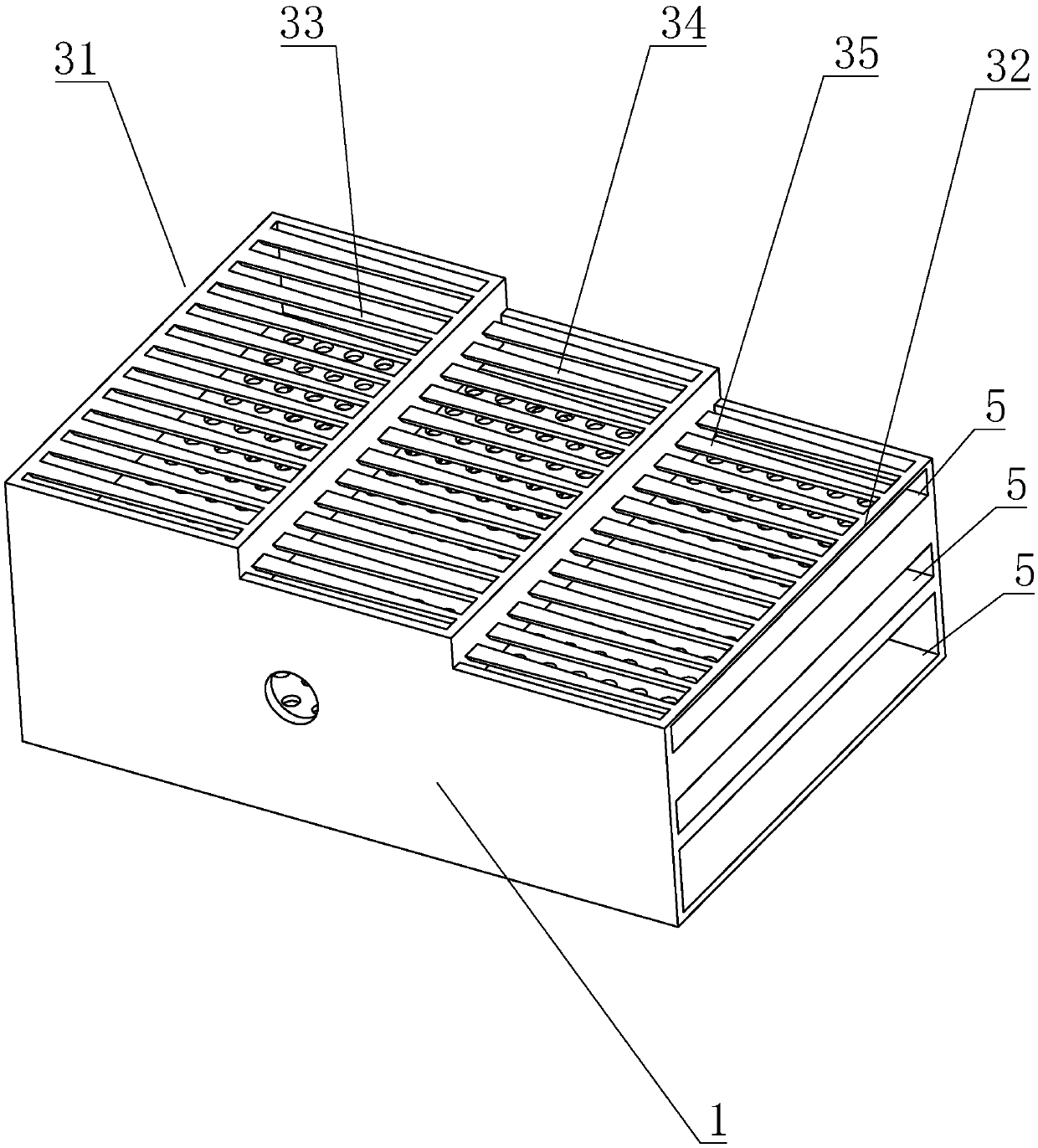

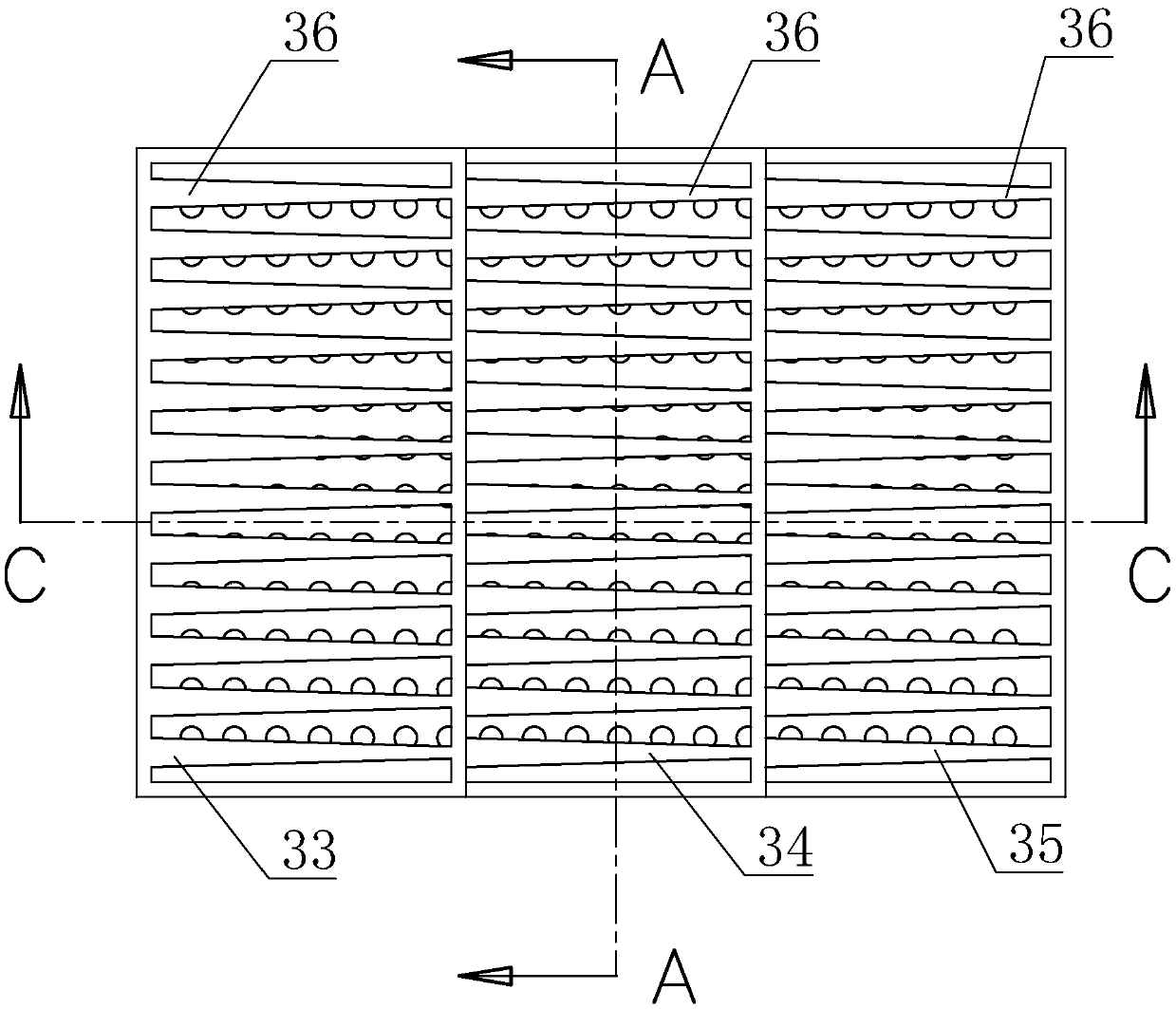

[0032] Please refer to Figure 1-6 As shown, a kind of mud-removing feeder includes a vibrating box 1 and a vibrating device 2; the vibrating box 1 is a hollow structure, and the upper end surface of the vibrating box 1 is a feeding conveying surface 3, and the feeding conveying surface 3 One end is the feed end 31, and the corresponding other end is the discharge end 32. The feeding and conveying surface 3 includes three conveying surfaces, and the three conveying surfaces are continuously connected along the route of mineral material, arranged in order from high to low, forming a ladder For the convenience of description, it is defined as the first conveying surface 33, the second conveying surface 34, and the third conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com