PE blown film, PE composite film, packaging bag and preparation method of packaging bag

A packaging bag and composite film technology, which is applied in the field of double-volume intercommunicable flexible packaging bags and packaging bags, can solve the problem that it is difficult for end consumers to uncover the separation area, the composite film material is insufficiently sealed, and the bag making operation is difficult to control, etc. problems, to achieve the effects of wide controllable range of bag making, improved heat sealing strength, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

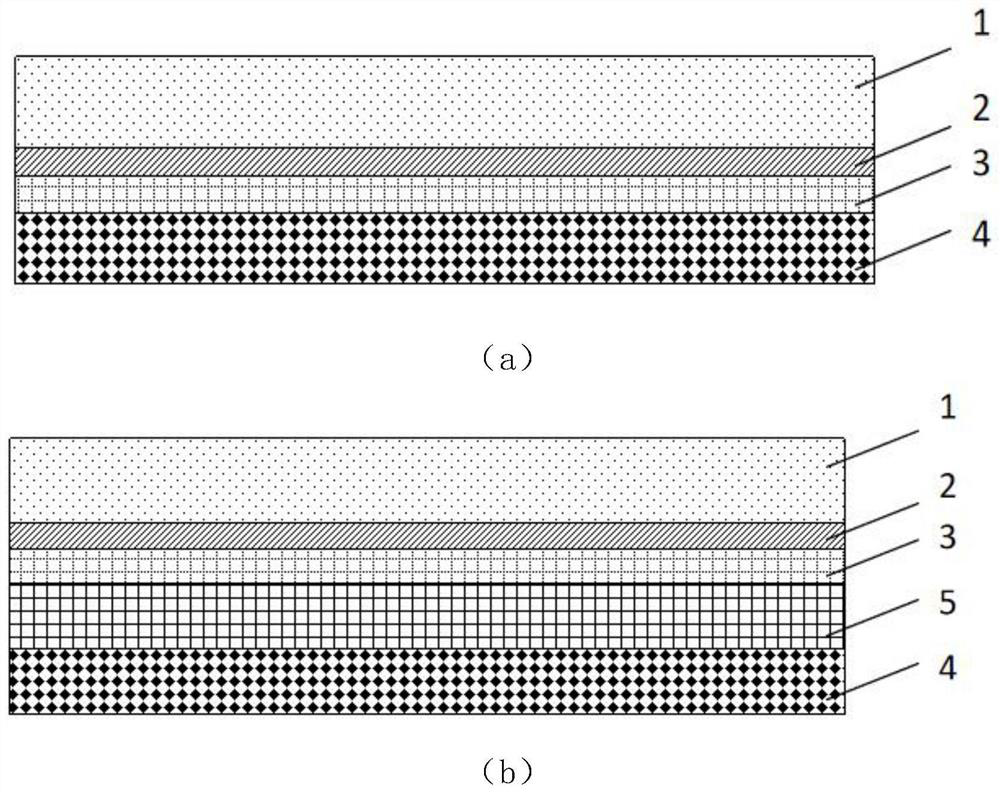

Image

Examples

Embodiment 1

[0046] S1. According to the formula composition of the first composite layer, the first core layer and the first heat-sealing layer in the PE blown film shown in Table 2 below, weigh the components in parts by weight, and then use the three-layer co-extrusion blown film process Film making, PE blown film 1 is obtained;

[0047] According to the formula composition of the second heat-sealing layer, the second core layer, and the third heat-sealing layer in the PE strip shown in Table 2 below, weigh the components in parts by weight, and then use the three-layer co-extrusion blown film process to make a film , to obtain PE strip 1;

[0048] According to the formula composition of the second heat-sealing layer, the second core layer, and the third heat-sealing layer in the PE strip shown in Table 2 below, weigh the components in parts by weight, and then use the three-layer co-extrusion blown film process to make a film , to obtain PE strip 2;

[0049] The properties of each pa...

Embodiment 2

[0058] Renovate the bag-making equipment, add a PE strip unwinding device in the middle of the upper and lower films, use the PE composite film 1 and PE strip 1 prepared above to prepare a double-volume intercommunicable flexible packaging bag; when the PE composite film is on the bag-making machine When it is cut into upper and lower pieces, the width of heat-sealed PE strip 1, that is, the heat-sealed length is 1mm, 2mm, 3mm, 4mm, 5mm, and 6mm respectively. Put the PE strips between two pieces of PE composite film 1, heat seal The temperature is 135°C, the heat-sealing time is 0.5s, and the heat-sealing pressure is 180KPa. Heat-seal the surroundings of two pieces of PE composite film 1 and the 1st area of the PE strip. When the PB content in the heat-sealing layer of the PE strip is 50%, the different Intercommunicable flexible packaging bags 1-6 with separate areas of transverse heat-sealed length;

[0059] Measure the heat-seal strength of the compartmentalized area pack...

Embodiment 3

[0062] Renovate the bag-making equipment, add a PE strip unwinding device in the middle of the upper and lower films, use the PE composite film 1 and PE strip 2 prepared above to prepare a double-volume intercommunicable flexible packaging bag; when the PE composite film is on the bag-making machine When cut into upper and lower pieces, put the heat-sealed PE strips 2 with widths of 4mm, 6mm, 8mm, 10mm, 12mm, and 14mm, respectively, between two pieces of PE composite film 1, and heat-seal them. The temperature is 135°C, the heat-sealing time is 0.5s, and the heat-sealing pressure is 180KPa. Heat-seal the surroundings of two pieces of PE composite film 1 and the 2nd area of the PE strip. When the PB content in the heat-sealing layer of the PE strip is 75%, different Intercommunicable flexible packaging bags 7-12 with separate areas of transverse heat-sealed length;

[0063] Measure the heat-seal strength of the packaging bags with different transverse heat-seal lengths prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com