New energy axle swing arm processing tooling

A new energy and axle technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of low productivity of special-shaped parts, machining accuracy can not meet the requirements, etc., to achieve high machining accuracy, high machining efficiency, and improve machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

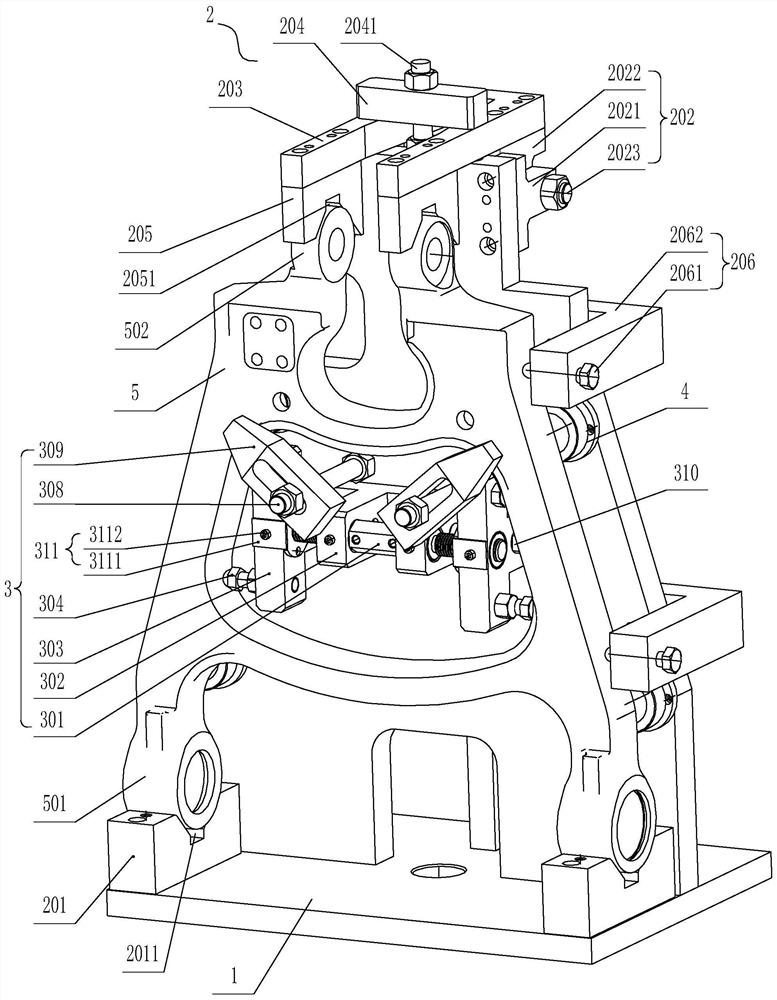

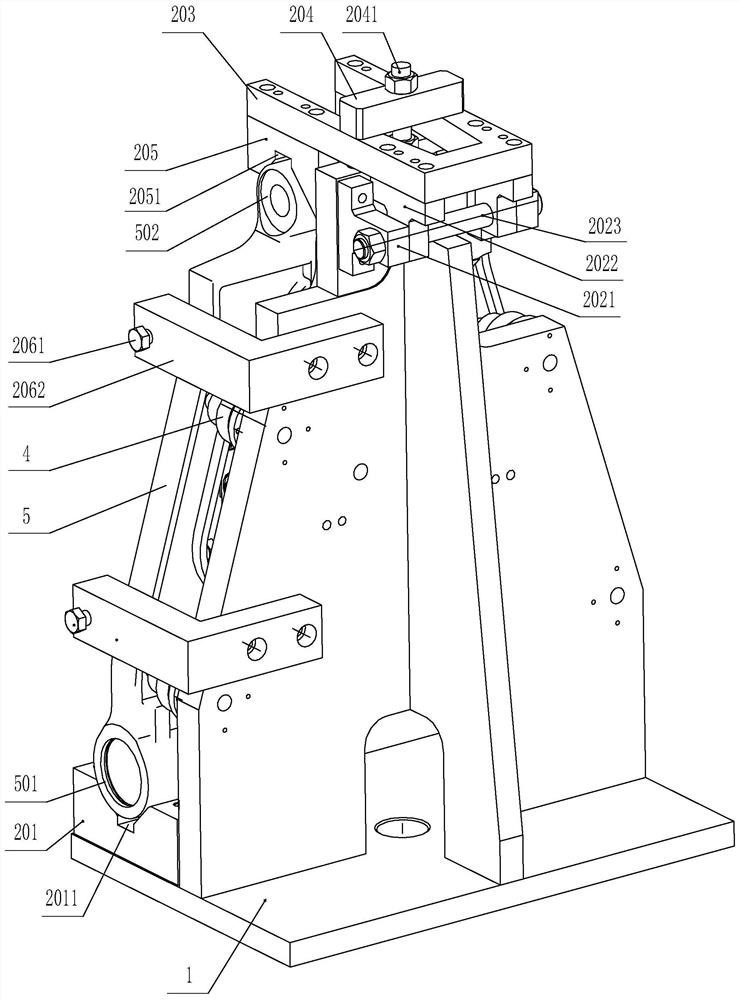

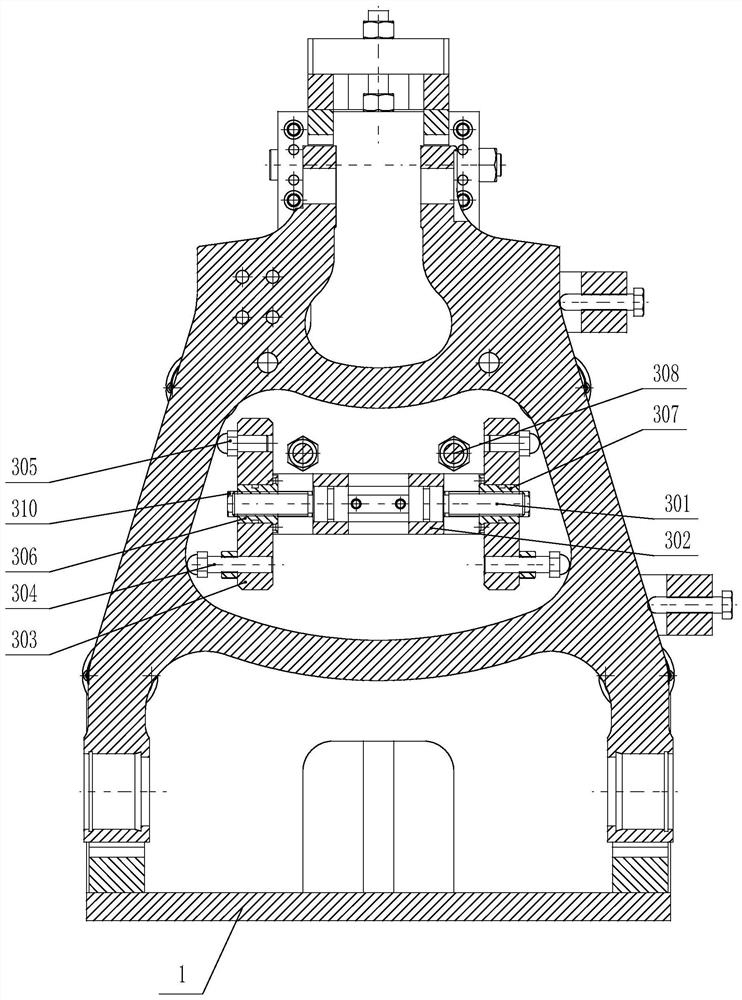

[0061] A new energy axle swing arm processing tooling, comprising a base 1, a swing arm outer contour positioning device 2 respectively installed on the base 1, a swing arm inner contour positioning device 3, and an elastic auxiliary support assembly 4, wherein:

[0062] The base 1 is used as the entire tooling support, including a base plate 101, a vertical plate 102, and a support plate 103. The bottom ends of the vertical plate 102 and the support plate 103 are respectively welded and fixed on the base plate 101, and the support plate 103 It is welded and fixed on one side of the vertical plate 102 so as to support the vertical plate 102 .

[0063] The swing arm outer contour positioning device 2 includes two V-shaped positioning blocks I 201, two hinge mechanisms 202, V-shaped positioning block II fixing plate 203, pressure plate 204, two V-shaped positioning blocks II 205, and a side end limit device 206; the two V-shaped positioning blocks I201 are respectively fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com