Sugarcane peeling device for agricultural production

A sugar cane and peeling technology, applied in the application, vegetable or fruit peeling, food science and other directions, can solve the problems of inability to clean the circular arc cutter, can not meet the needs of people, and affect the sugarcane peeling work, etc. To facilitate unloading work, avoid damage, and avoid the effect of knife jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

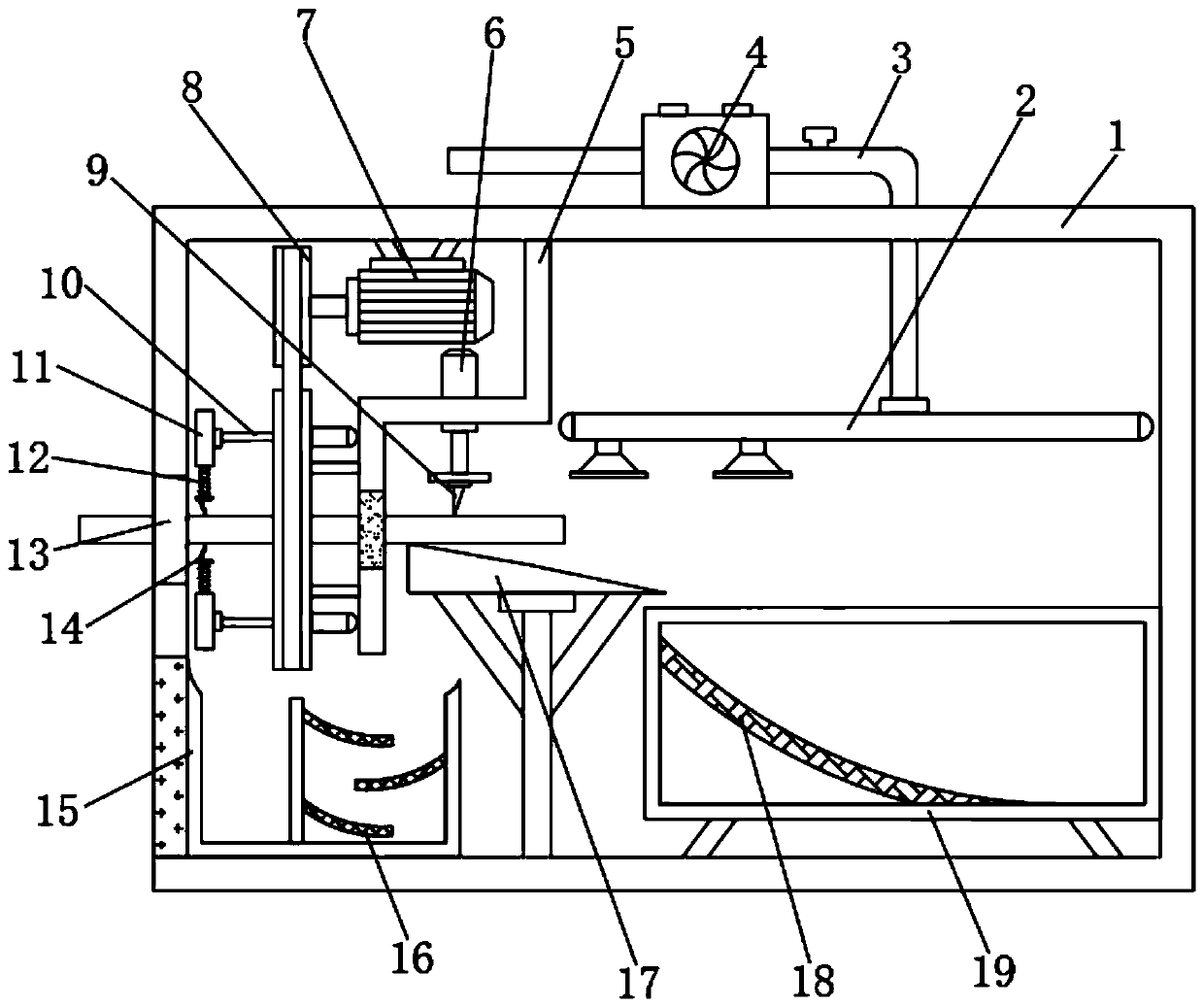

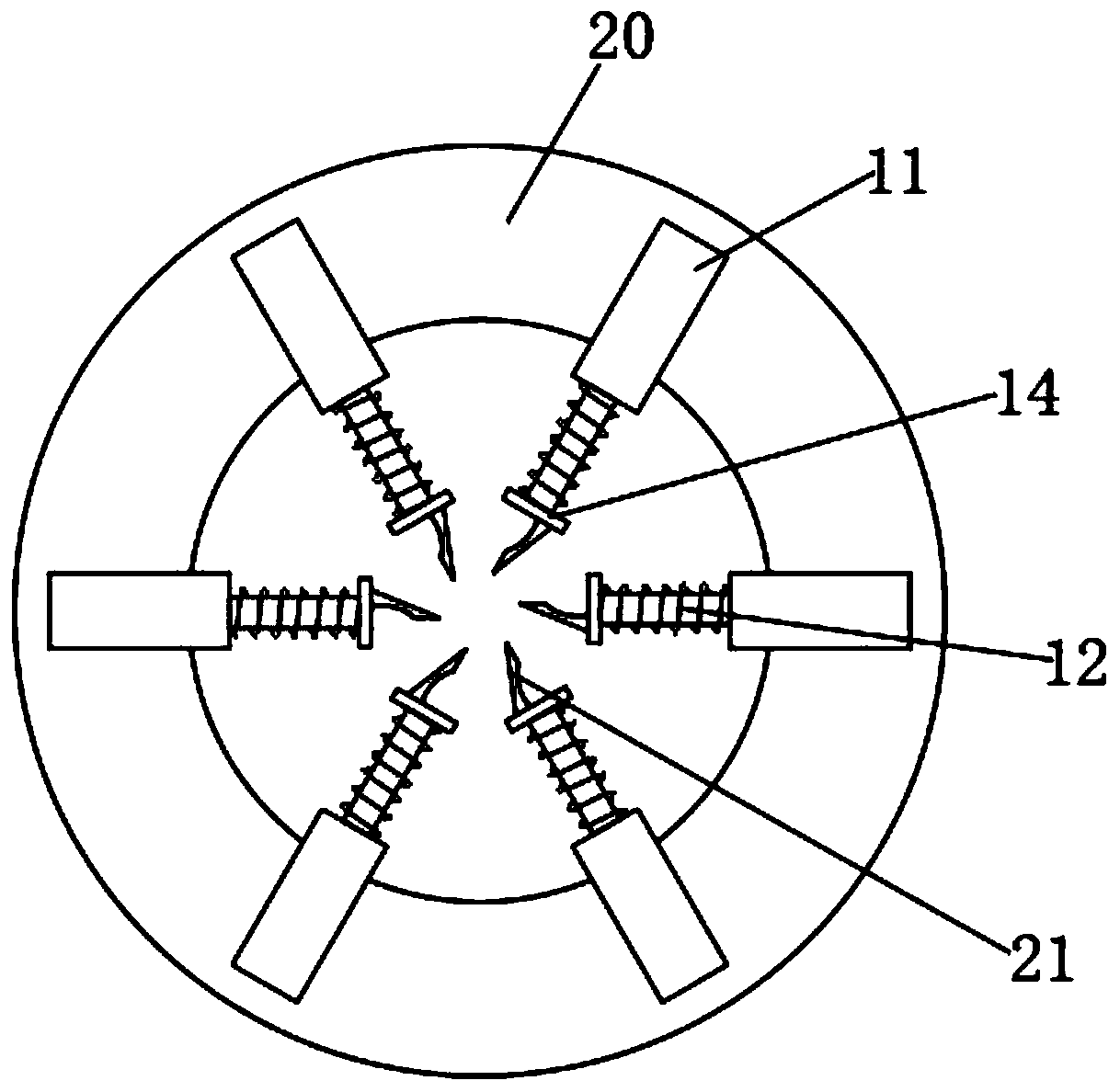

[0033] refer to Figure 1-4 , a sugarcane peeling device for agricultural production, comprising a box body 1, a side outer wall of the box body 1 is provided with a feed port 13, and the inside of the feed port 13 is inserted with a sugarcane body, and the top inner wall of the box body 1 is passed through a bolt The first motor 7 is connected, and the outer wall of one end of the output shaft of the first motor 7 is fixedly connected with a driving wheel 8, the outer wall of the driving wheel 8 is connected with a transmission belt, and the inner wall of one side of the transmission belt is connected with a driven wheel 20, and One side of the outer wall of the driven wheel 20 is plugged with second electric push rods 10 equidistant and annularly distributed, and one end of the second electric push rod 10 is connected with a sleeve 11 by bolts, and one end of the sleeve 11 is plugged with a slide Column 25, the circumferential outer wall of sliding column 25 is sleeved with ...

Embodiment 2

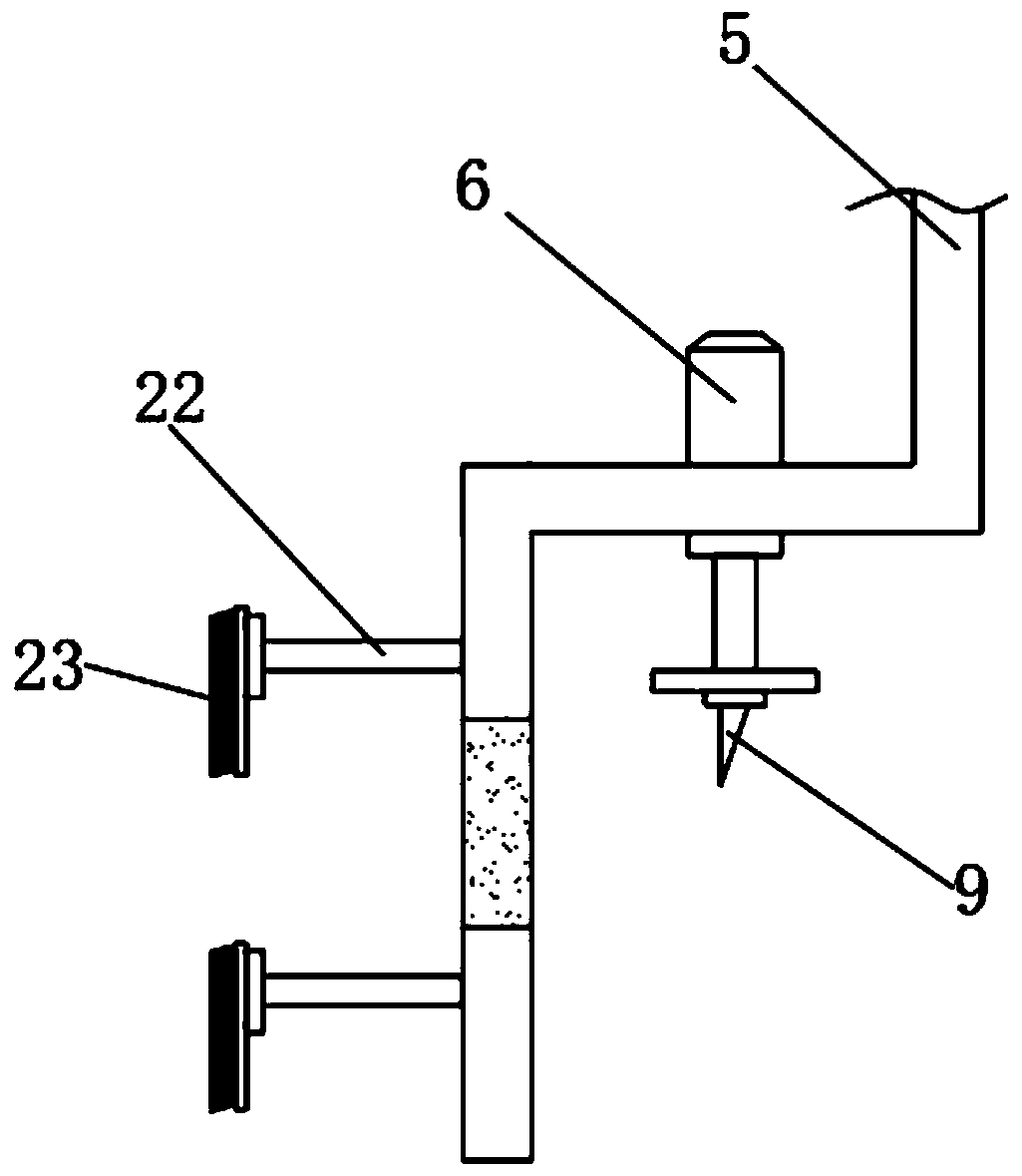

[0037] refer to Figure 5 , a sugarcane peeling device for agricultural production. Compared with Embodiment 1, the outer wall of one side of the sleeve 11 has a round hole, and the inner wall of one side of the sleeve 11 is connected with a second motor 24 by bolts. The outer wall of one end of the output shaft of the second motor 24 is connected with a rope receiving roller 27 by bolts, and the peripheral outer wall of the rope receiving roller 27 is wound with a traction rope 26, and the output shaft of the second motor 24 passes in the circular hole, and the fixed plate 14 The top outer wall is welded with a fixed seat, and the end of the traction rope 26 away from the rope take-up roller 27 is bolted on the top outer wall of the fixed seat.

[0038] Working principle: when in use, people can start the second motor 24 before peeling the sugarcane, and the second motor 24 carries out the work of winding up the traction rope 26, and then people insert the sugarcane in the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com