Shock resistance detection device for Beidou agricultural machinery positioning and monitoring terminal

A monitoring terminal and detection device technology, which is applied in the direction of measuring devices, machine/structural component testing, satellite radio beacon positioning systems, etc., can solve problems such as high vibration frequency, inability to adjust, large vibration amplitude, etc., to improve adaptability , Improve flexibility, low vibration frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

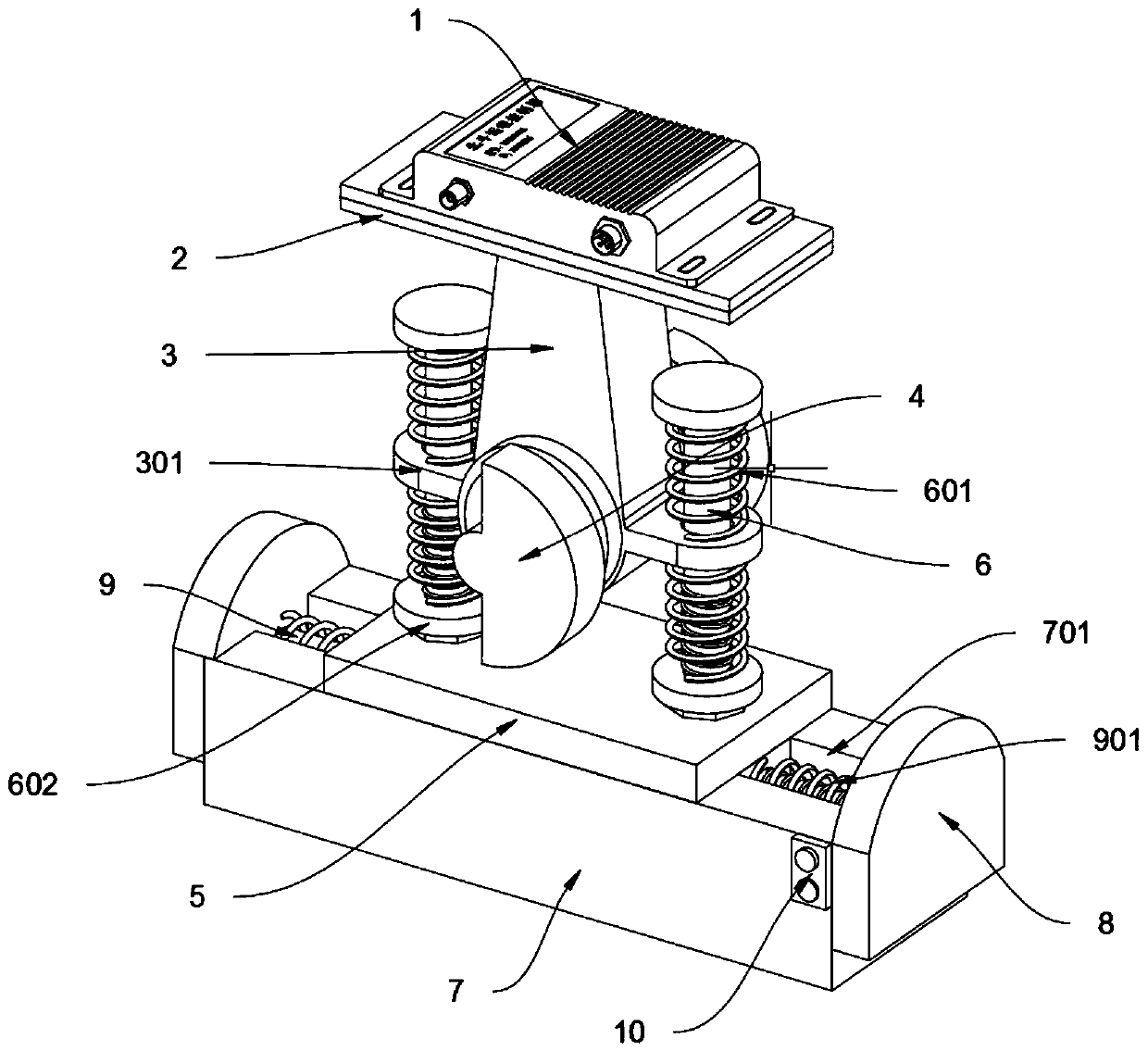

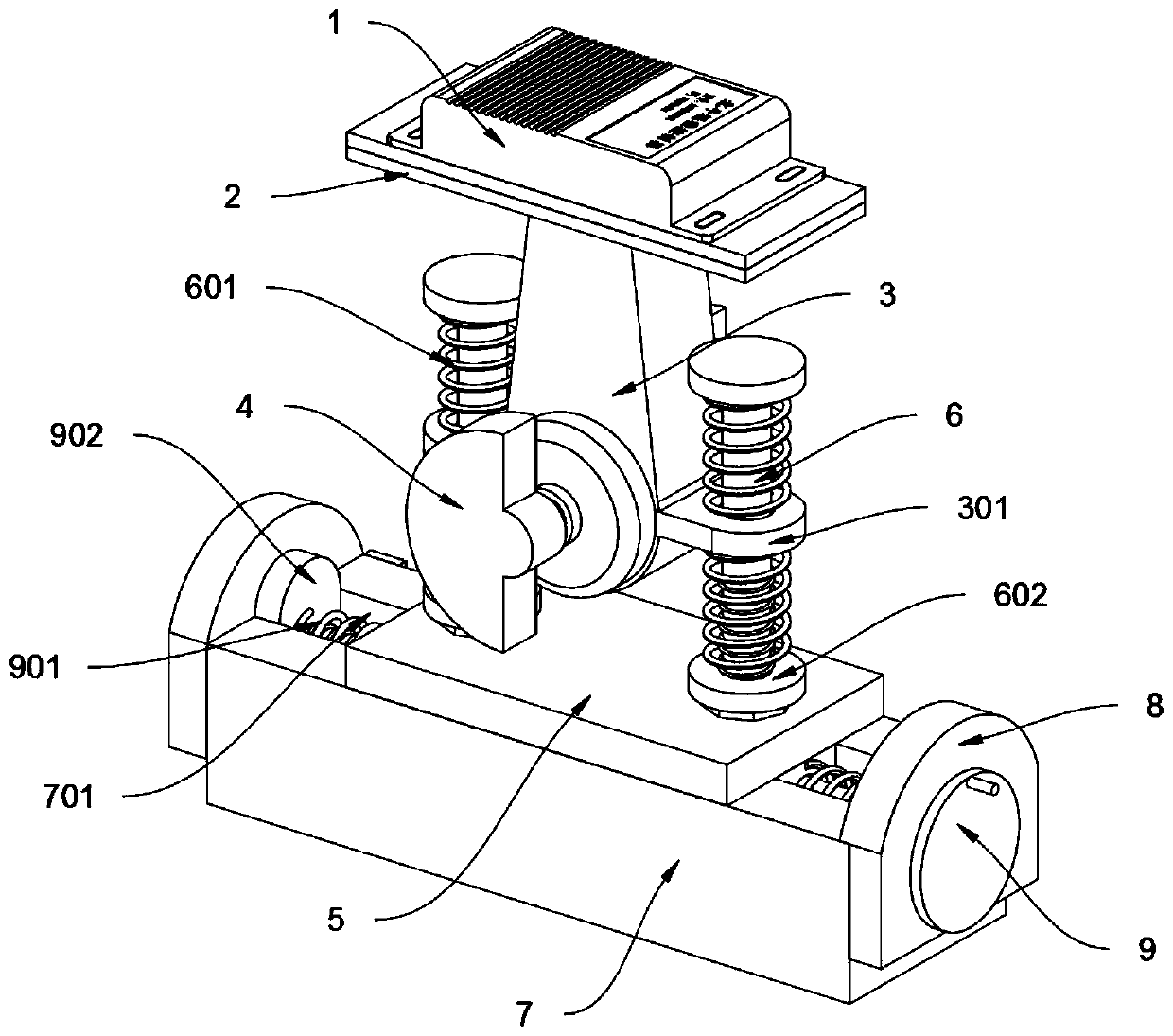

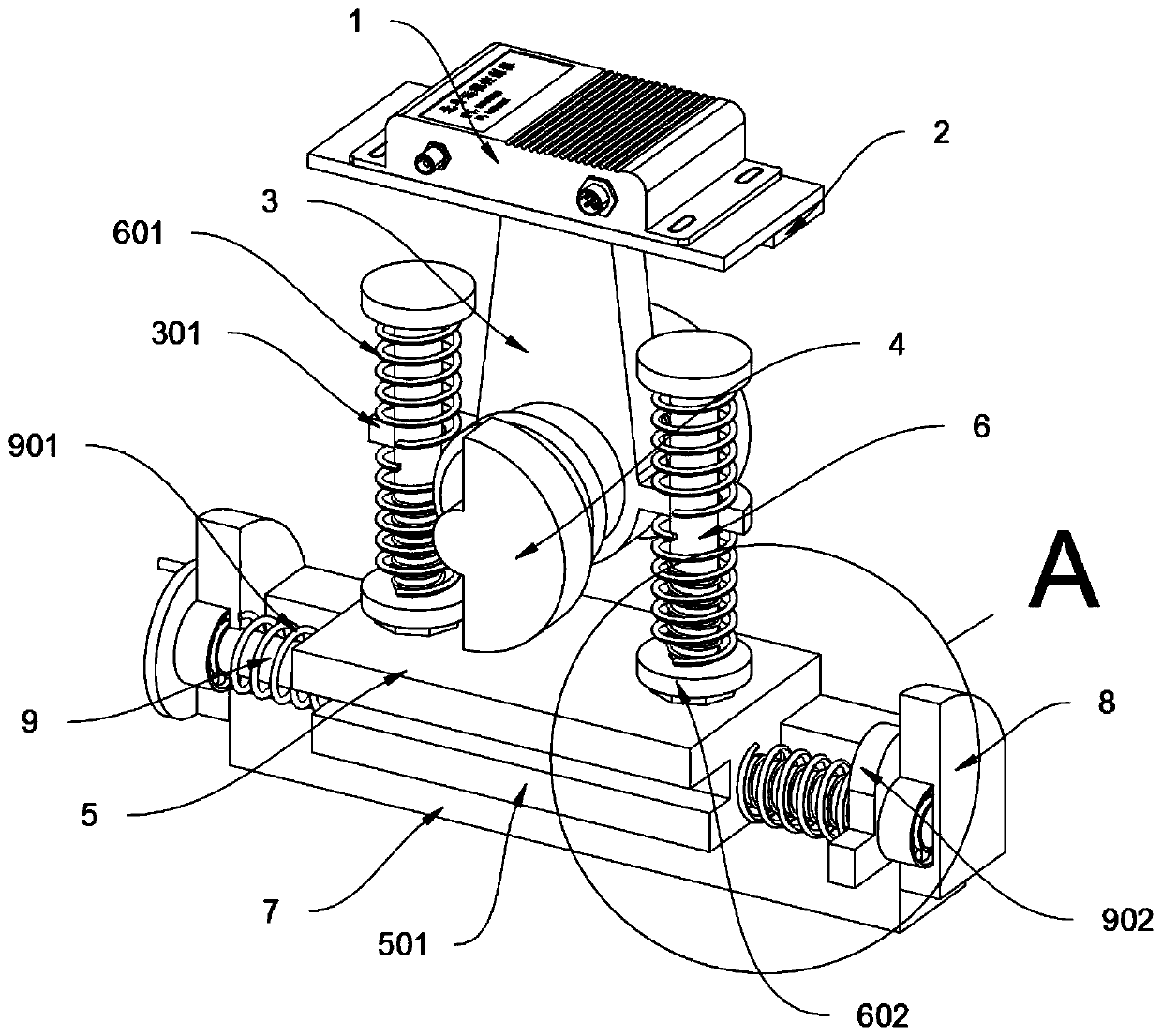

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The present invention provides a shock resistance detection device for Beidou agricultural machinery positioning monitoring terminal, including a monitoring controller 1, a horizontal test block 5, a longitudinal test rod 6, a side plate 8, an adjustment rod 9 and a control switch 10; the monitoring controller 1 It is screwed and fixed on the top of the test installation board 2; the test installation board 2 is fixedly connected to the top of the motor housing 3; the inside of the motor housing 3 is provided with a drive motor, and both ends of the drive motor shaft are fixedly connected with The vibrating block 4; the vibrating block 4 is a semicircular eccentric iron block, and the eccentric orientation of the vibrating block 4 at both ends of the drive motor shaft inside the motor housing 3 is the same, as shown in the attached figure 1 And attached figure 2 As shown, this design makes it possible for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com