Treatment system for exhaust with high oxygen content and treatment method thereof

A treatment system and treatment method technology, applied in the field of chemical equipment, can solve the problems of reducing economic value, increasing the investment cost of incinerators, wasting light fuel in venting exhaust gas, etc., so as to reduce environmental protection investment, reduce design treatment volume, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

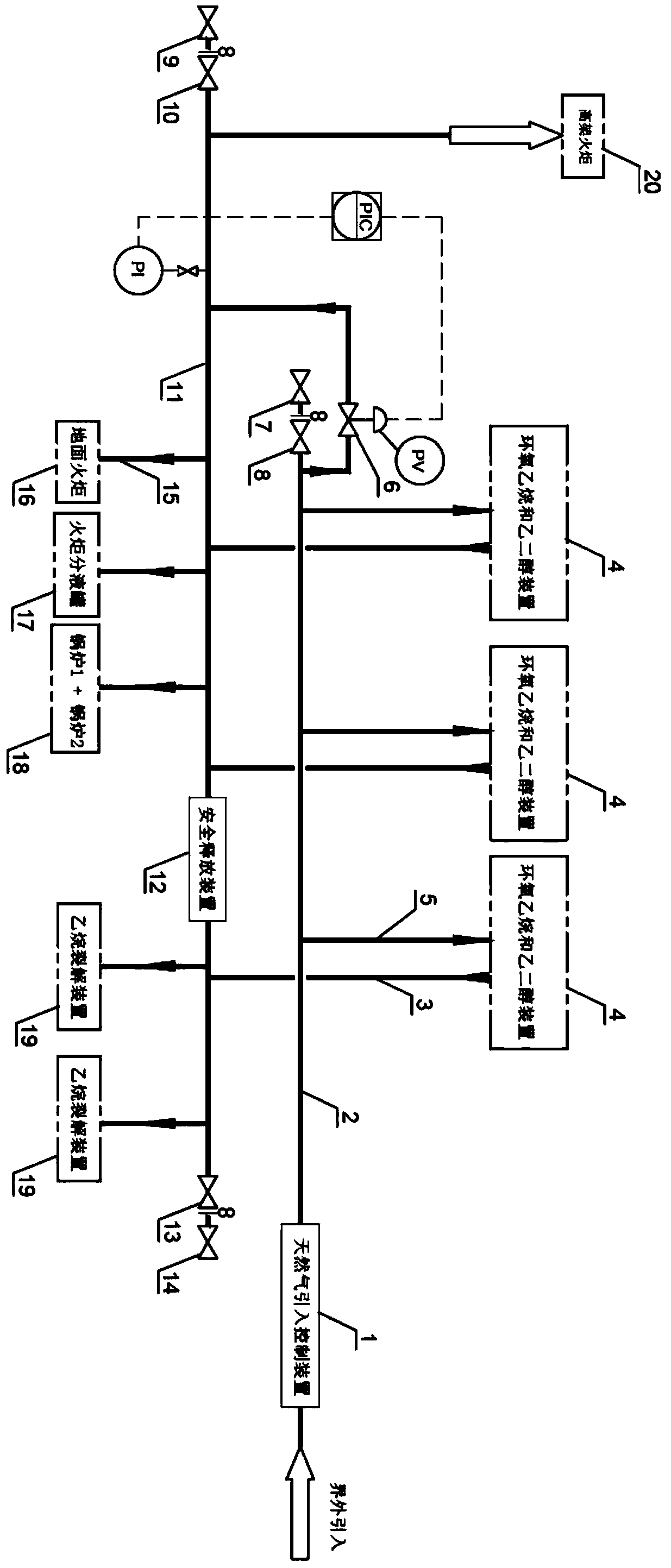

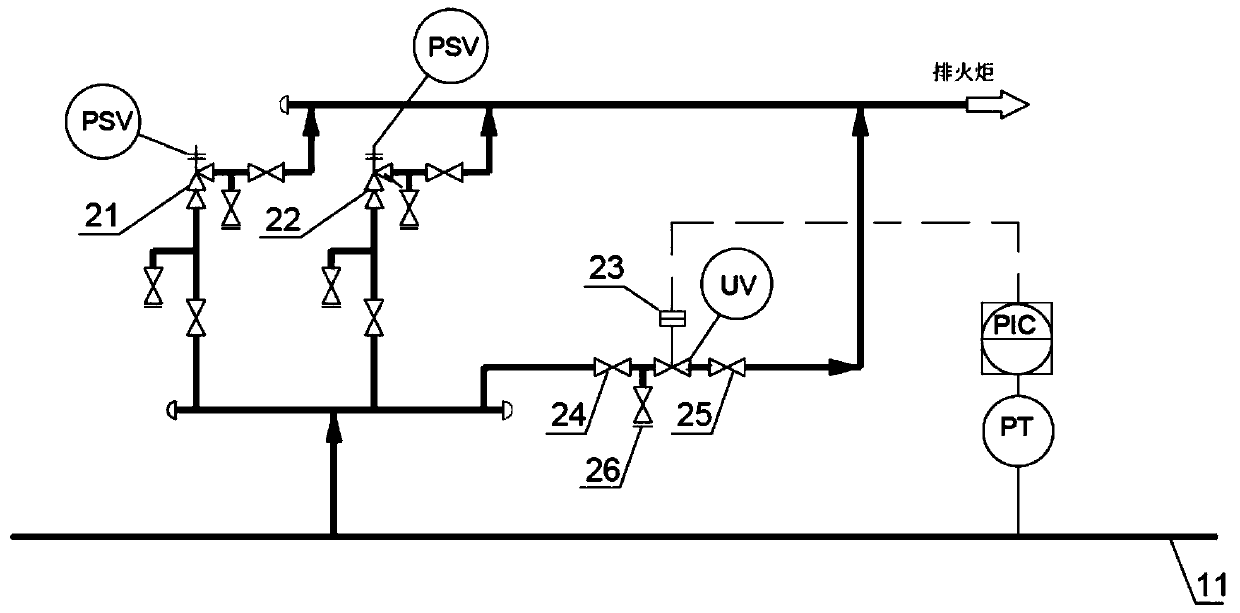

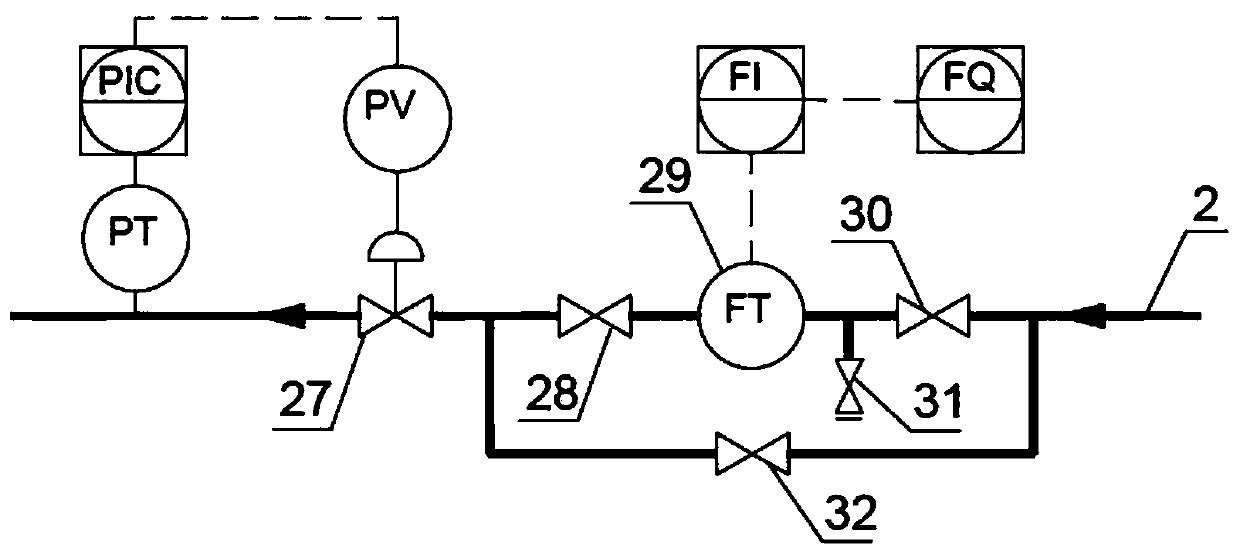

Embodiment 1

[0033] A fuel gas system for processing high-oxygen tail gas, comprising a first system 2 and a second system 11, closing valve b 7, valve c 8, valve d 9, valve e 10, valve f 13, and valve g 14, Valve k 26, valve q 31, valve r 32. Open valve i 24, valve j 25, valve n 28, and valve p 30. The valve m 27 is set to automatically control the pressure at 0.6Mpa. The pressure regulating valve a 6 is set to automatically control the pressure to 0.4Mpa. The first safety valve 21 and the second safety valve 22 ensure that the front and rear valves are opened and put into use, and are regularly inspected. The valve h 23 is set to the interlocking state, the upper limit of the interlock is 0.42Mpa, and the lower limit of the interlock is 0.35Mpa. The fuel gas goes to each user, and there are valves in the user boundary area. The user can take the gas freely. The pressure of the fuel gas system is stable and reliable, and the exhaust gas is connected to the grid safely and smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com