Cusped magnetic field plasma thruster

A plasma and tangent magnetic field technology, applied in the field of plasma thrusters, can solve the problems of insufficient ionization of gas working fluid and slow heat dissipation in the air gap, and achieve the effects of avoiding paramagnetic phenomenon, improving life, and avoiding magnetic tip phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] Due to the complex movement trajectories of electrons and ions in the ionization channel of the tangential magnetic field plasma thruster in the electric field and magnetic field, it is greatly affected by the inner wall structure of the ionization channel, so a large number of analysis and experimental studies are required for different channel sections .

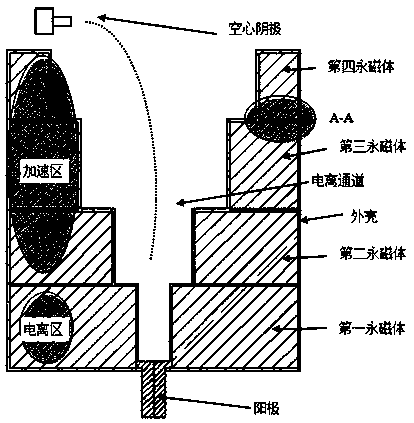

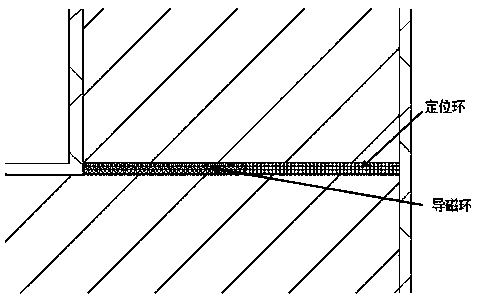

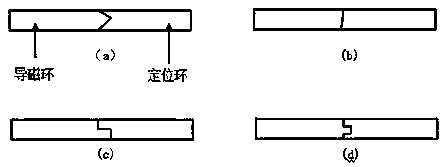

[0033] Such as figure 1 As shown, the tangential field plasma thruster of the present invention includes an ionization channel, a permanent magnet, an anode, a hollow cathode, a magnetically permeable ring, a positioning ring and a casing, an anode is provided at the bottom of the ionization channel, and a hollow cathode is provided at the outlet. The area between the outer wall of the ionization channel and the outer shell is sequentially provided with first, second, third and fourth perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com