Discharge chamber of a ring-type ion thruster

A technology of ion thrusters and discharge chambers, applied in discharge tubes, ion beam tubes, circuits, etc., can solve the problems of limiting the thrust and specific impulse of ion thrusters, uneven distribution of plasma, and ionization area limitations, etc., to reduce The effect of discharge loss, improvement of ionization efficiency and uniformity of plasma distribution, and reduction of working fluid utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings and examples.

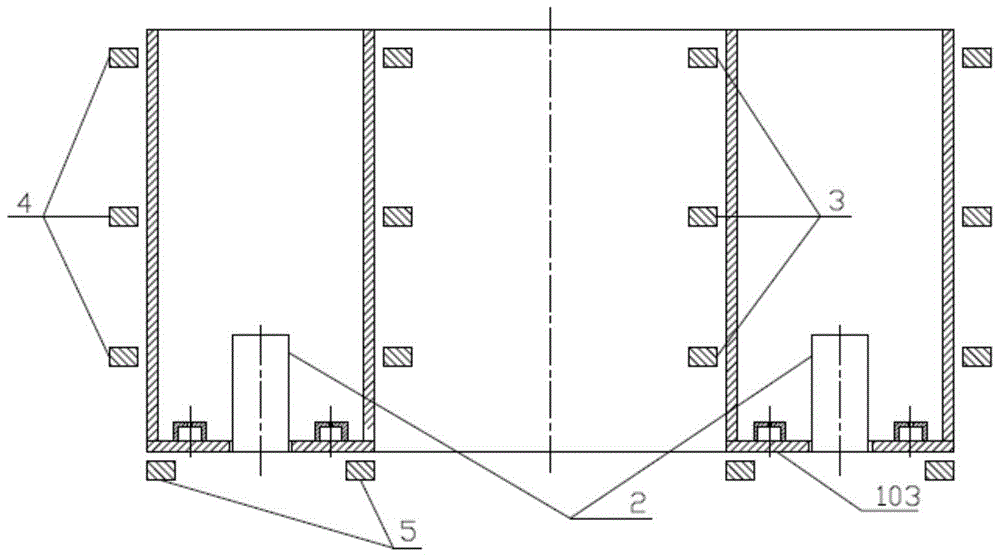

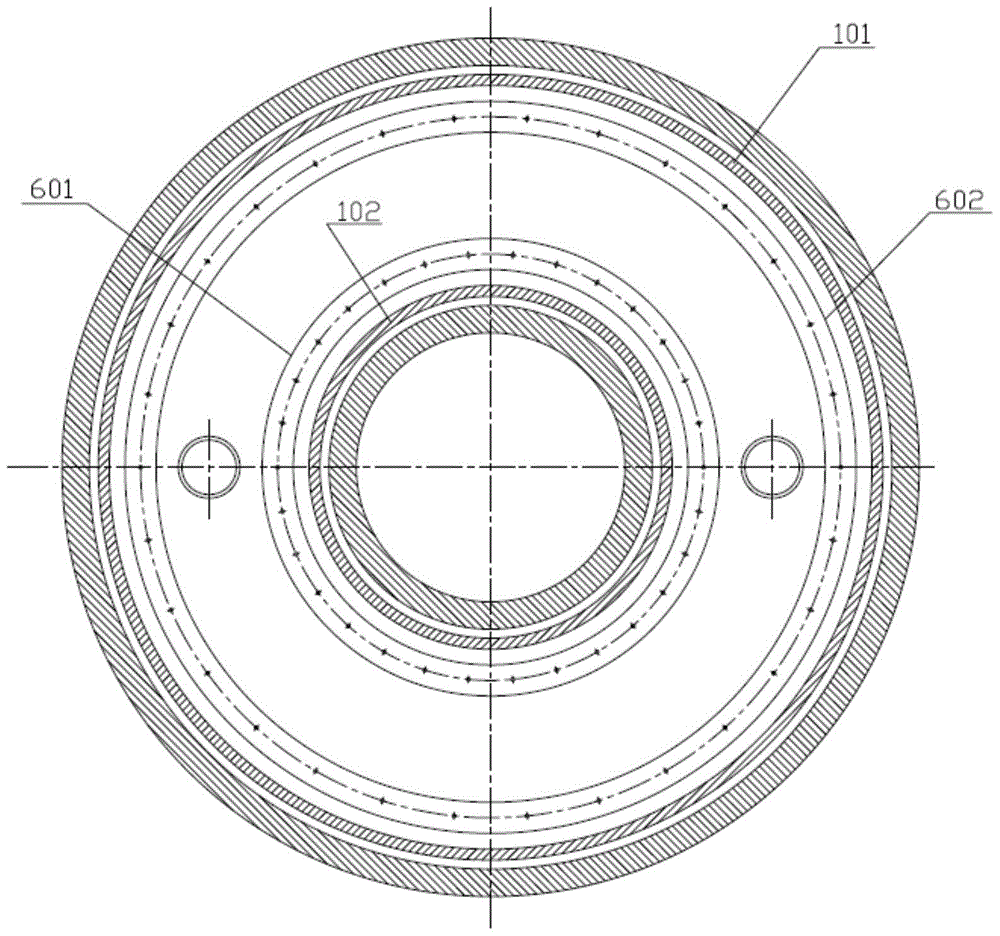

[0013] The invention provides a ring-type ion thruster discharge chamber, such as figure 1 and figure 2 As shown, it includes: an annular anode group, two cathodes 2, an annular magnetic pole group and a gas distribution ring. Among them, the ring-shaped anode group includes three parts: the outer ring anode 101, the inner ring anode 102 and the bottom anode 103. The inner ring anode 102 and the outer ring anode 101 are coaxial ring structures with equal lengths, and the bottom anode 103 is circular. The bottoms of the inner ring anode 102 and the outer ring anode 101 are respectively fixedly connected to the inner and outer circumferences of the bottom anode 103 to become one; the ring-type magnetic pole group includes the inner ring magnetic pole group 3, the outer ring magnetic pole group 4 and the bottom magnetic pole group 5, wherein , the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com