Negative ion water-based coating and preparation method thereof

A water-based paint and negative ion technology, applied in the field of paint, can solve the problems of destroying charge balance, agglomeration, affecting the uniformity of the dispersion of negative ion components, and achieve the effect of good negative ion release effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

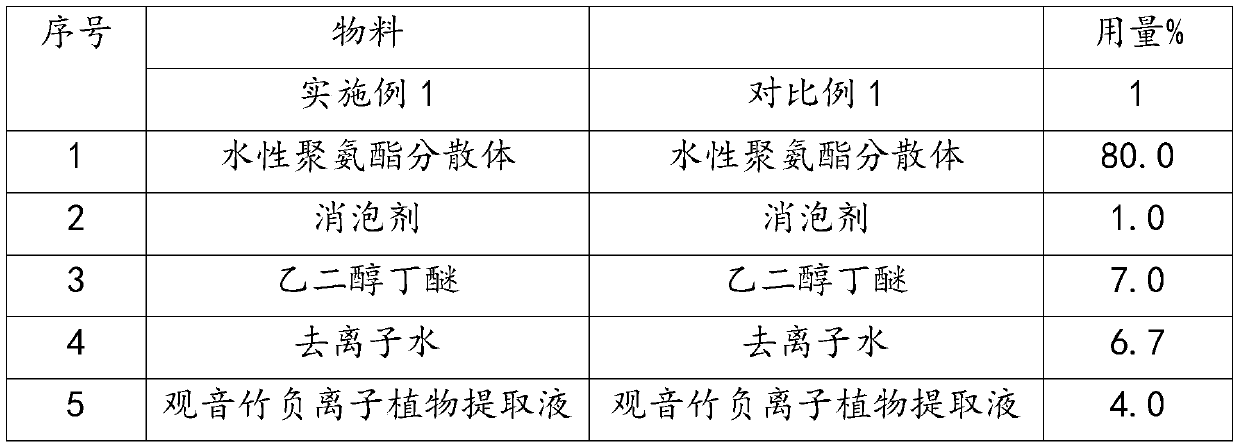

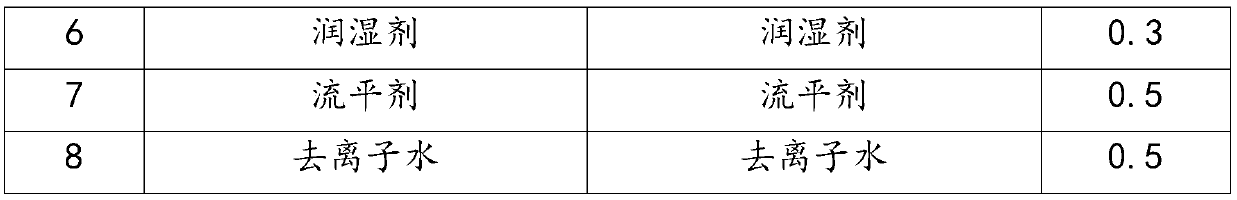

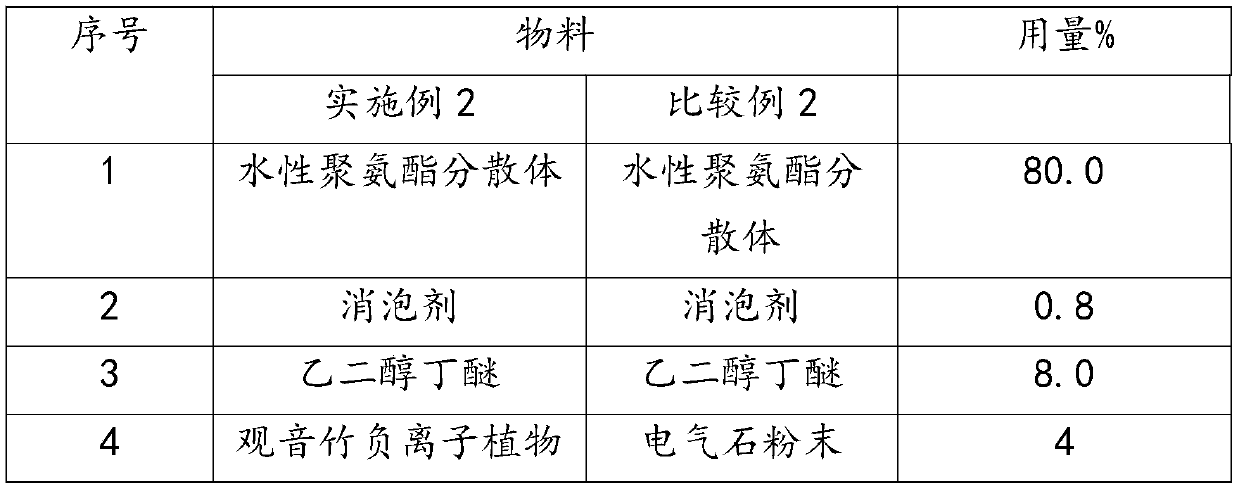

[0076] Embodiment 2 and comparative example 2 raw material ratio as shown in table 2, prepared is negative ion water-based wood finish.

[0077] Table 2

[0078]

[0079]

[0080] The present embodiment and comparative example comprise the following steps:

[0081] The first step is to accurately weigh component 1, and add the premixed components 2-7 groups under the 300-rpm stirrer to stir, and maintain the stirring speed at 300 rpm;

[0082] In the second step, adjust the rotation speed to 400 rpm, add the diluted components of components 8 and 9, and defoam at a slow speed for 10 minutes.

[0083] In this embodiment and comparative example, the pH value of coating remains between 7-8, and aqueous polyurethane dispersion is detected by molecular detector, and molecular particle size is at 6-8 micron, and Guanyin bamboo is through 2000 revolutions in embodiment 2 High-speed friction, detected by a molecular detector, the molecular particle size is in the range of 6-8 ...

Embodiment 3

[0084] Embodiment 3 Raw material ratio is as shown in table 3, prepared is negative ion water-based sealing primer.

[0085] table 3

[0086]

[0087]

[0088] This embodiment includes the following steps:

[0089] The first step is to accurately weigh 1 component, add 2-8 components under the condition of 400 rpm stirring, adjust to 1000 rpm and stir for 5 minutes;

[0090] In the second step, add components 9-11 and stir for 10 minutes under the stirring condition of 400 rpm;

[0091] In the third step, 12 components are added to adjust the viscosity.

[0092] In this embodiment, the pH value of the coating remains between 7-8, and the acrylic polyester emulsion is detected by a molecular detector, and the molecular particle size is within the range of 6-8 microns. Speed friction, detected by molecular detector, the molecular particle size is in the range of 6-8 microns, the main performance indicators of embodiment 3: solid content 35%, viscosity 65MPa.s, negativ...

Embodiment 4

[0093] Example 4 Raw material ratio as shown in Table 4, prepared is negative ion water-based matt finish for woodware.

[0094] Table 4

[0095]

[0096]

[0097] The preparation method is as follows:

[0098] The first step is to accurately weigh 1 component and add 2-8 under the condition of stirring at 400 rpm to stir evenly for 10-20 minutes;

[0099] In the second step, under the stirring condition of 800 rpm, add 9-12 components and stir evenly for 15 minutes;

[0100] In the third step, add 13 to adjust the viscosity (MPa.s) under the stirring condition of 300 rpm.

[0101] In this embodiment, the pH value of the coating remains at 7-8, and the acrylic polyester emulsion is detected by a molecular detector. Detected by a molecular detector, the molecular particle size is in the range of 6-8 microns, the main performance indicators of embodiment 4: solid content 40%, viscosity 70MPa.s, gloss (60 °) is 20, negative ion release (1 cubic m square warehouse) 14000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com