An environment-friendly fiberglass septic tank installation and construction system and installation and construction process

A glass tempering and environment-friendly technology, applied in transportation and packaging, load suspension components, load pulleys, etc., can solve the problems of time-consuming and labor-intensive installation and construction operations, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

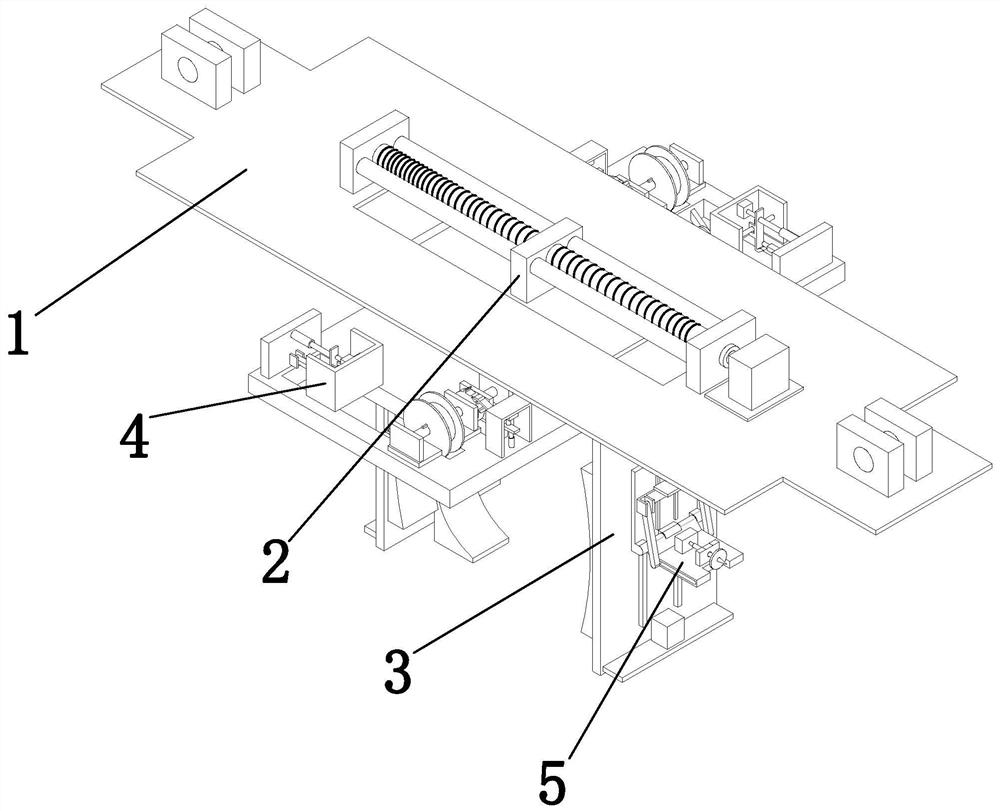

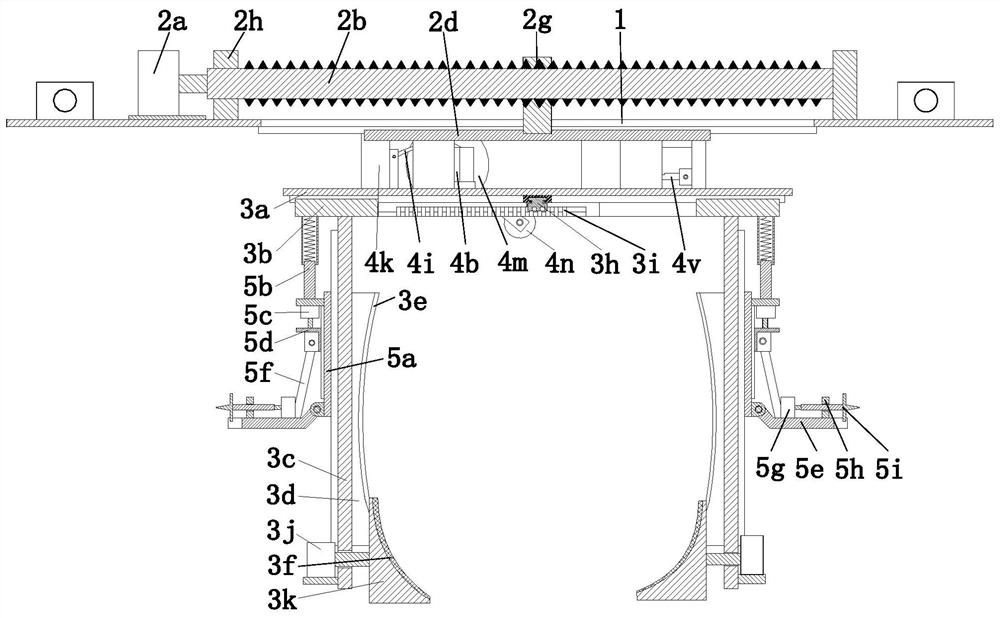

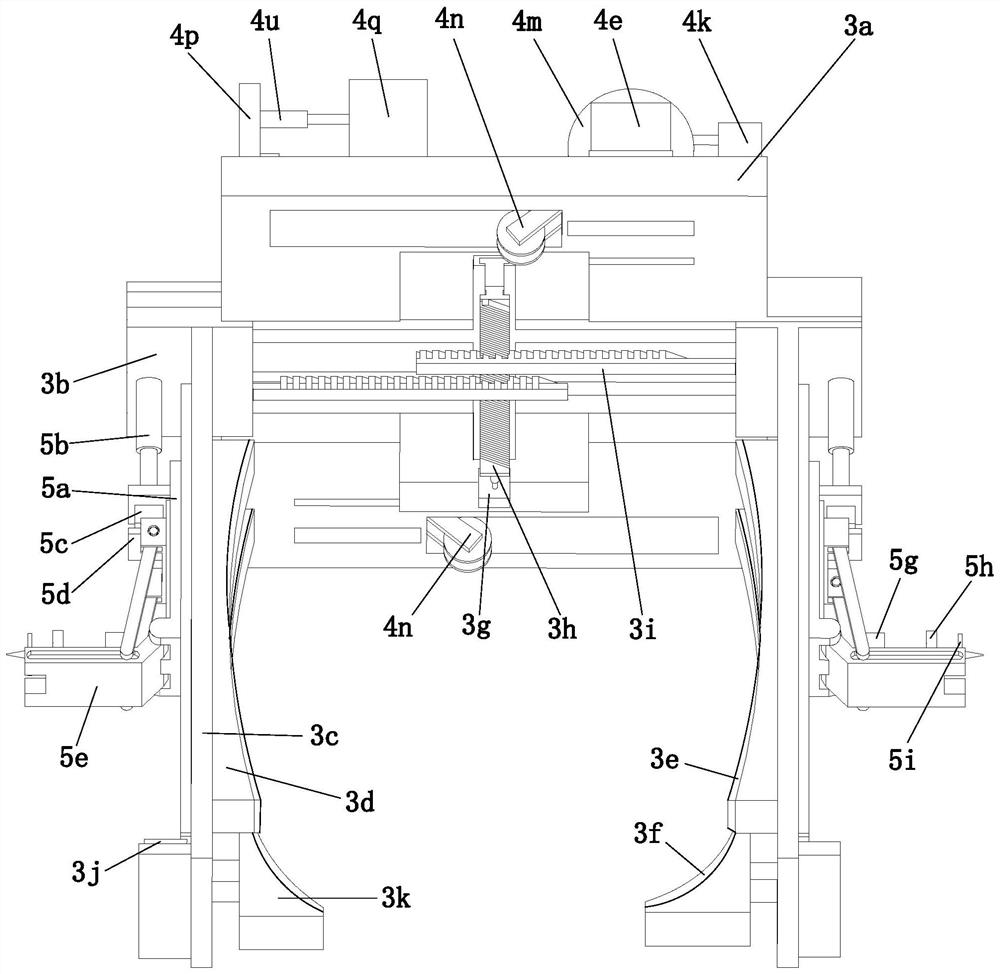

[0032] Such as Figure 1 to Figure 6 As shown, an environment-friendly FRP septic tank installation and construction system includes a hoisting plate 1, a shifting mechanism 2, a clamping mechanism 3, a sling winding mechanism 4 and a positioning mechanism 5, and the hoisting plate 1 is symmetrically arranged There are slide rails, a shifting mechanism 2 is installed on the lifting plate 1 through sliding fit, a clamping mechanism 3 is installed on the shifting mechanism 2, a suspension rope winding mechanism 4 is symmetrically installed on the clamping mechanism 3, and a lifting mechanism 4 is installed on the clamping mechanism 3 Slide rails are symmetrically arranged, and a positioning mechanism 5 is symmetrically installed on the clamping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com