Corrugated carton processing system

A processing system and corrugated box technology, applied in papermaking, paper/cardboard containers, dust removal, etc., can solve problems affecting the normal operation of corrugated box processing devices, damage to the bottom of cardboard, and inability to transport cardboard, so as to improve work enthusiasm and use Safe and convenient, reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

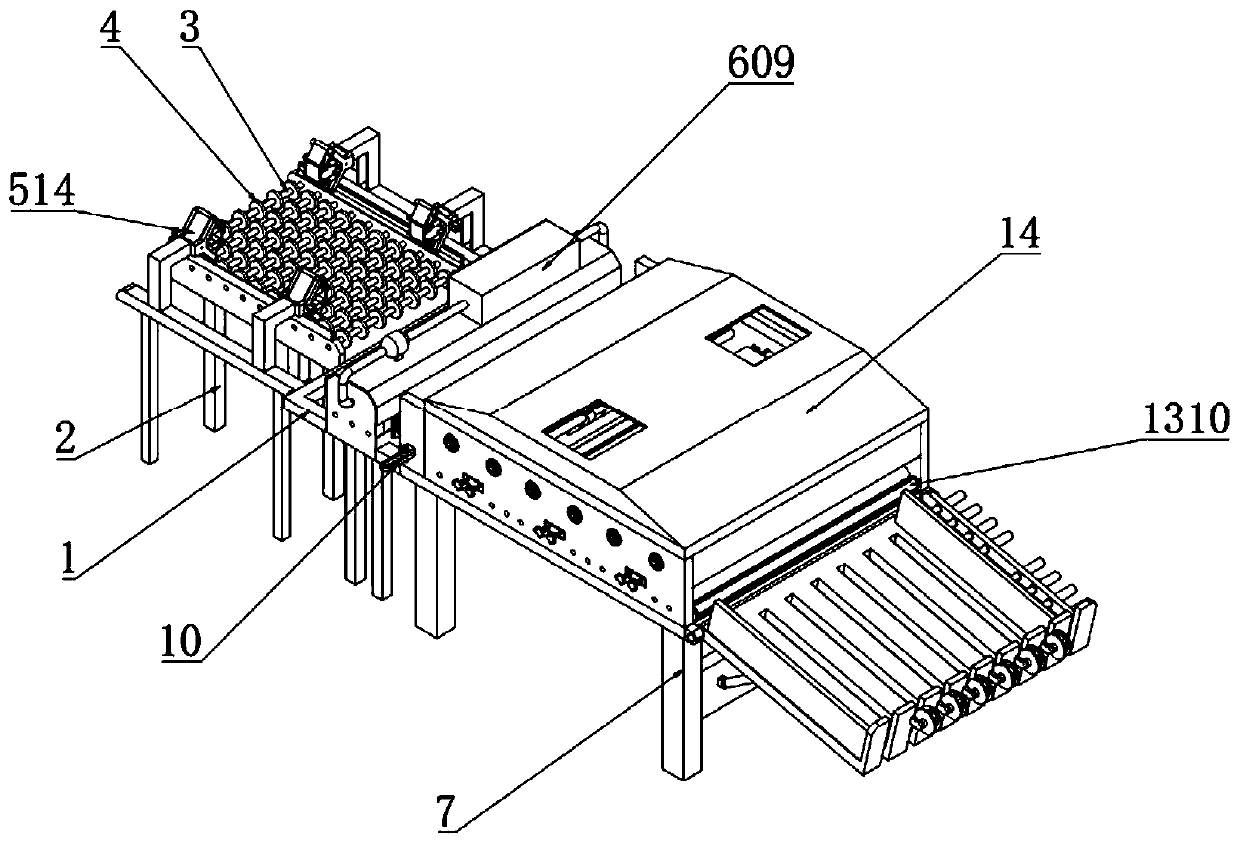

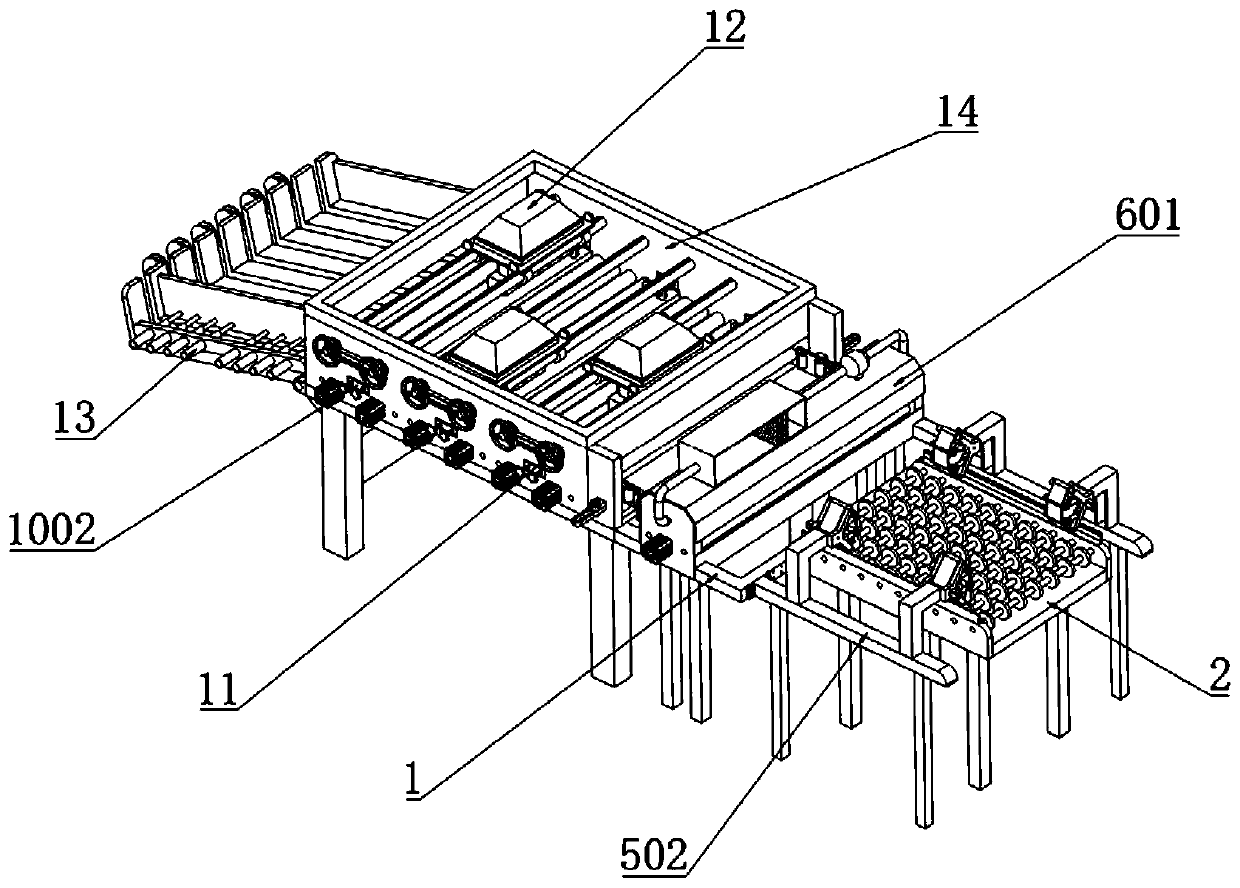

[0068] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a corrugated box processing system, including a connecting frame 1, a feeding frame 2 is welded to the middle part of one side of the connecting frame 1, and a driving rotating shaft 3 is connected to the middle part of the inner side of the feeding frame 2 for uniform rotation. , the outer side of the driving rotating shaft 3 is evenly and fixedly connected with a friction wheel 4, and one side of the connecting frame 1 is provided with a feeding support mechanism 5;

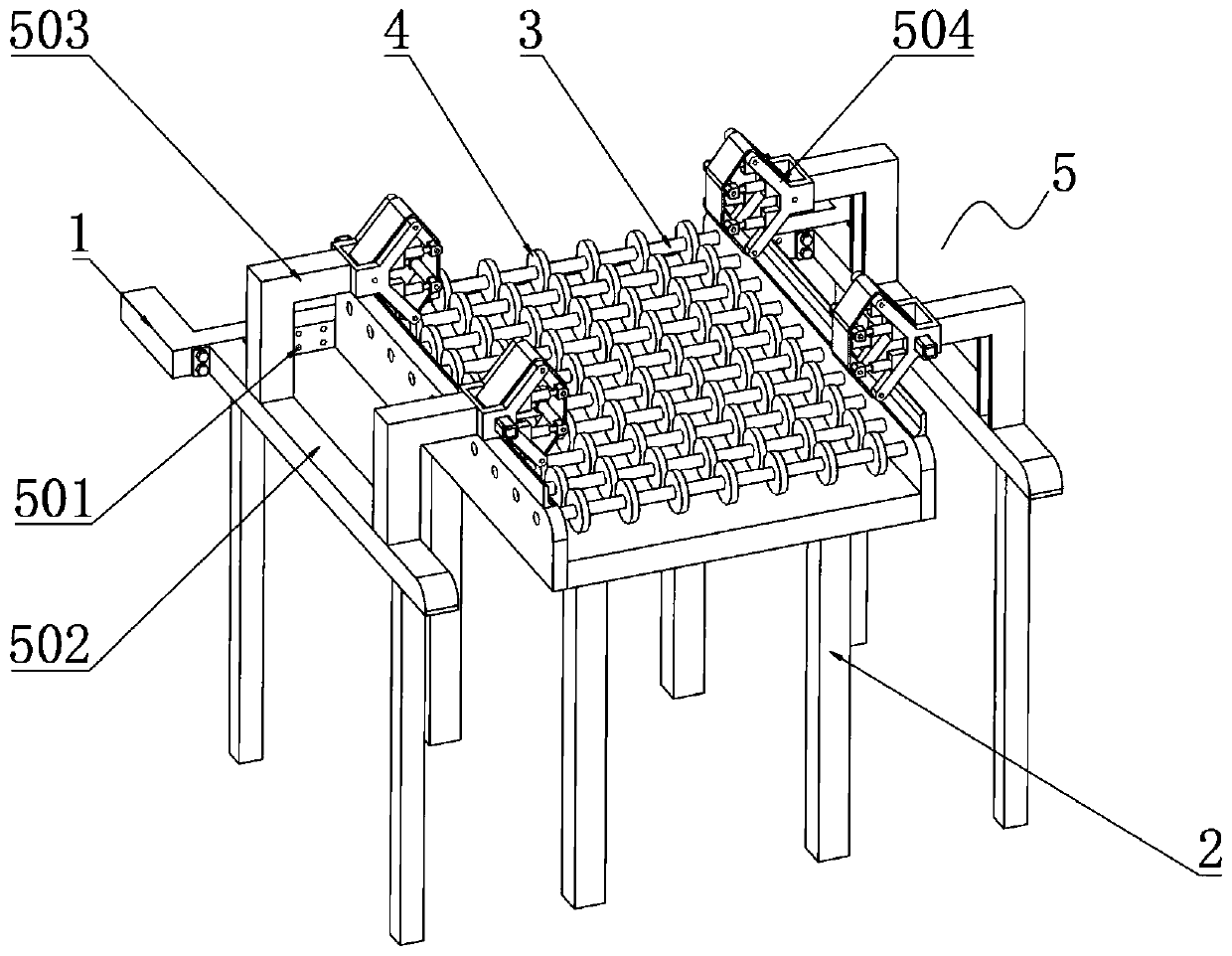

[0069] Feeding supporting mechanism 5 comprises mounting hole 501, mounting bracket 502, connecting bracket 503, mounting fan frame 504, stepping motor 505, driving roller 506, supporting roller 507, connecting triangular block 508, fixed pipe 509, clamping spring 510, Clamping slide bar 511, connecting block 512, clamping roller 513 and friction belt 514;

[0070] Both ends of one side of the connecting frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com