Chemical grouting mixing tank with stable structure and mounting method of chemical grouting mixing tank

A technology of chemical grouting and mixing tanks, which is applied in the direction of chemical instruments and methods, mixing operation control, clay preparation equipment, etc. It can solve the problems of affecting grouting operations, poor structural stability, and large volume of mixing tanks, so as to ensure firm installation High performance, compact and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

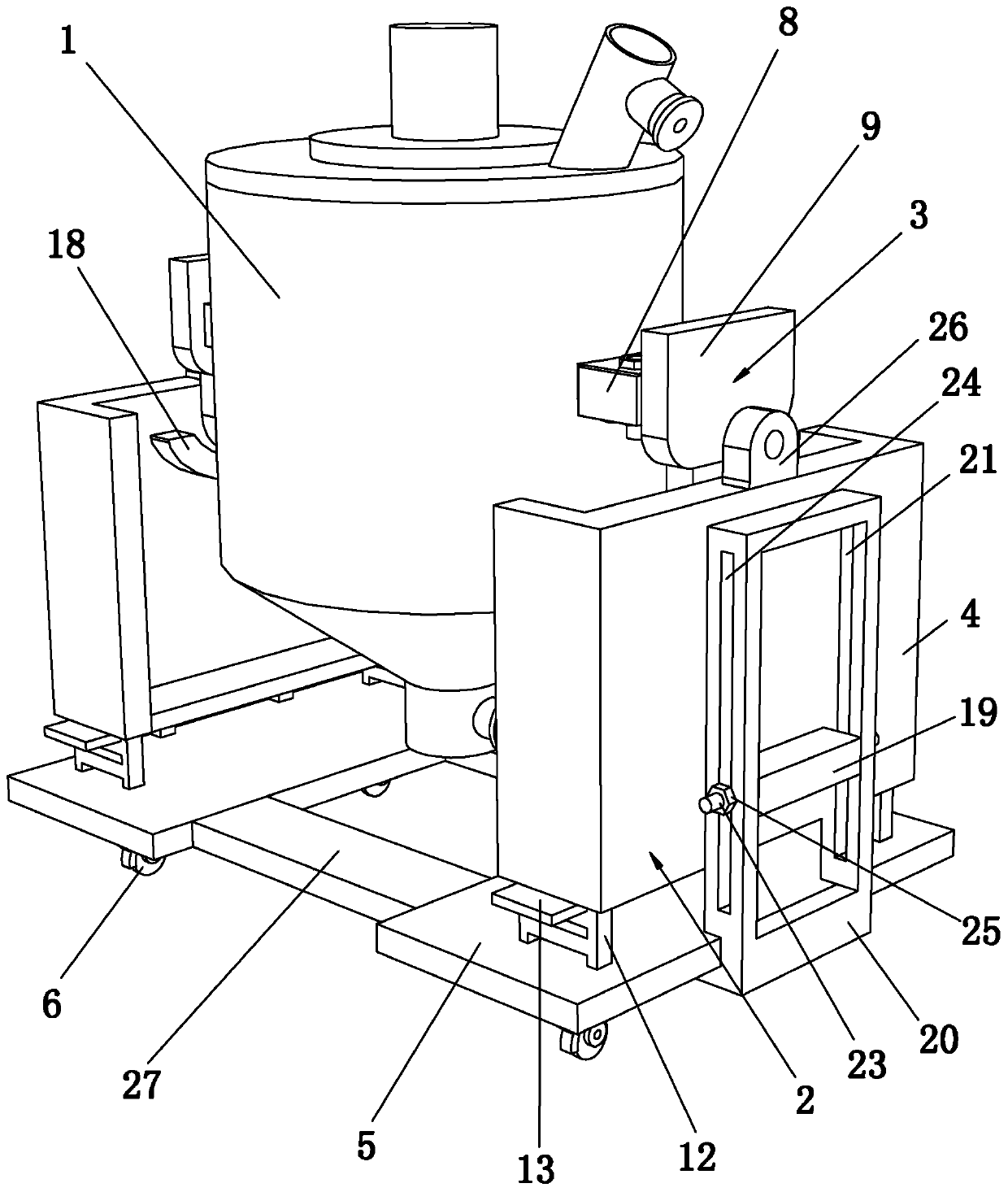

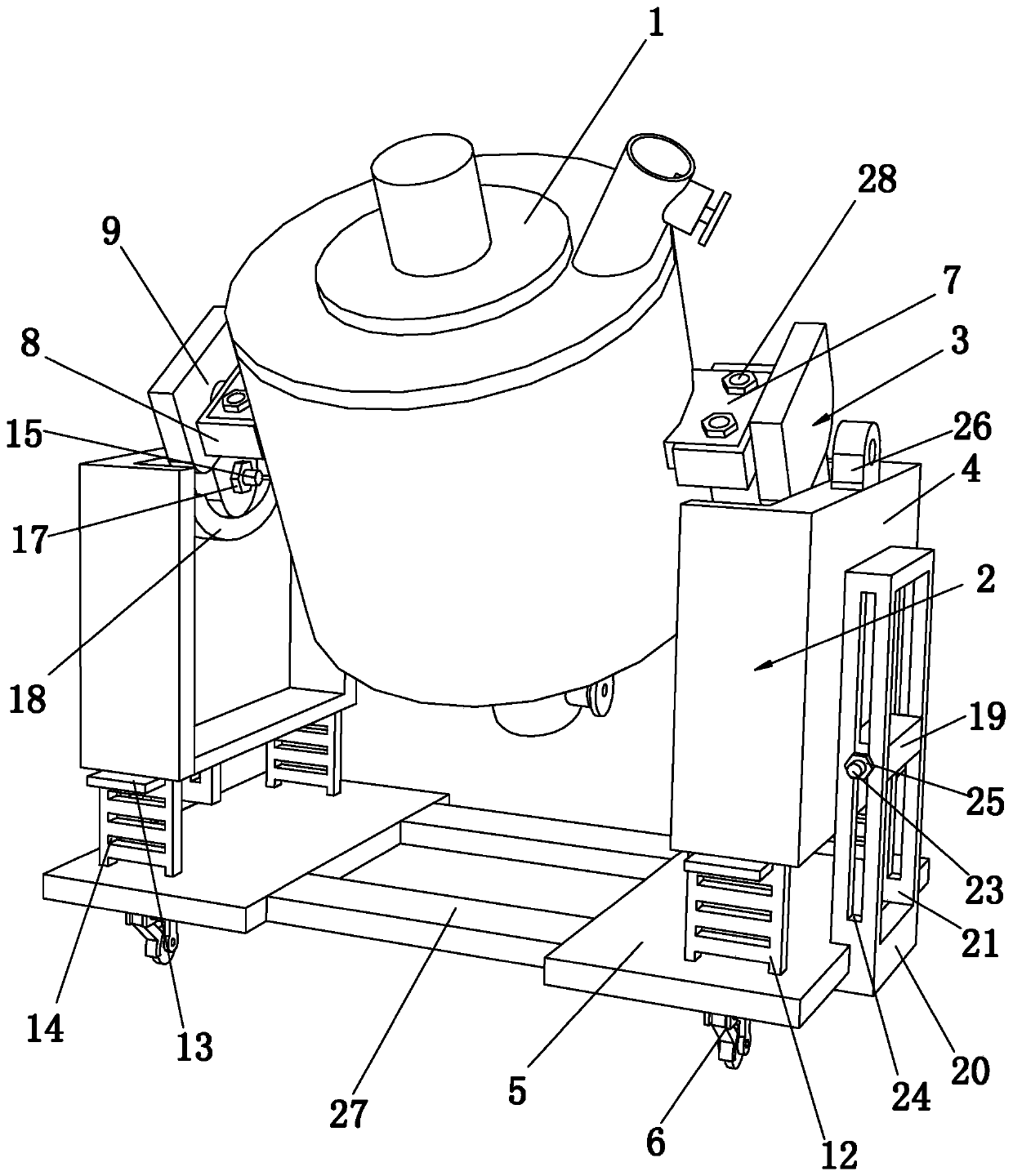

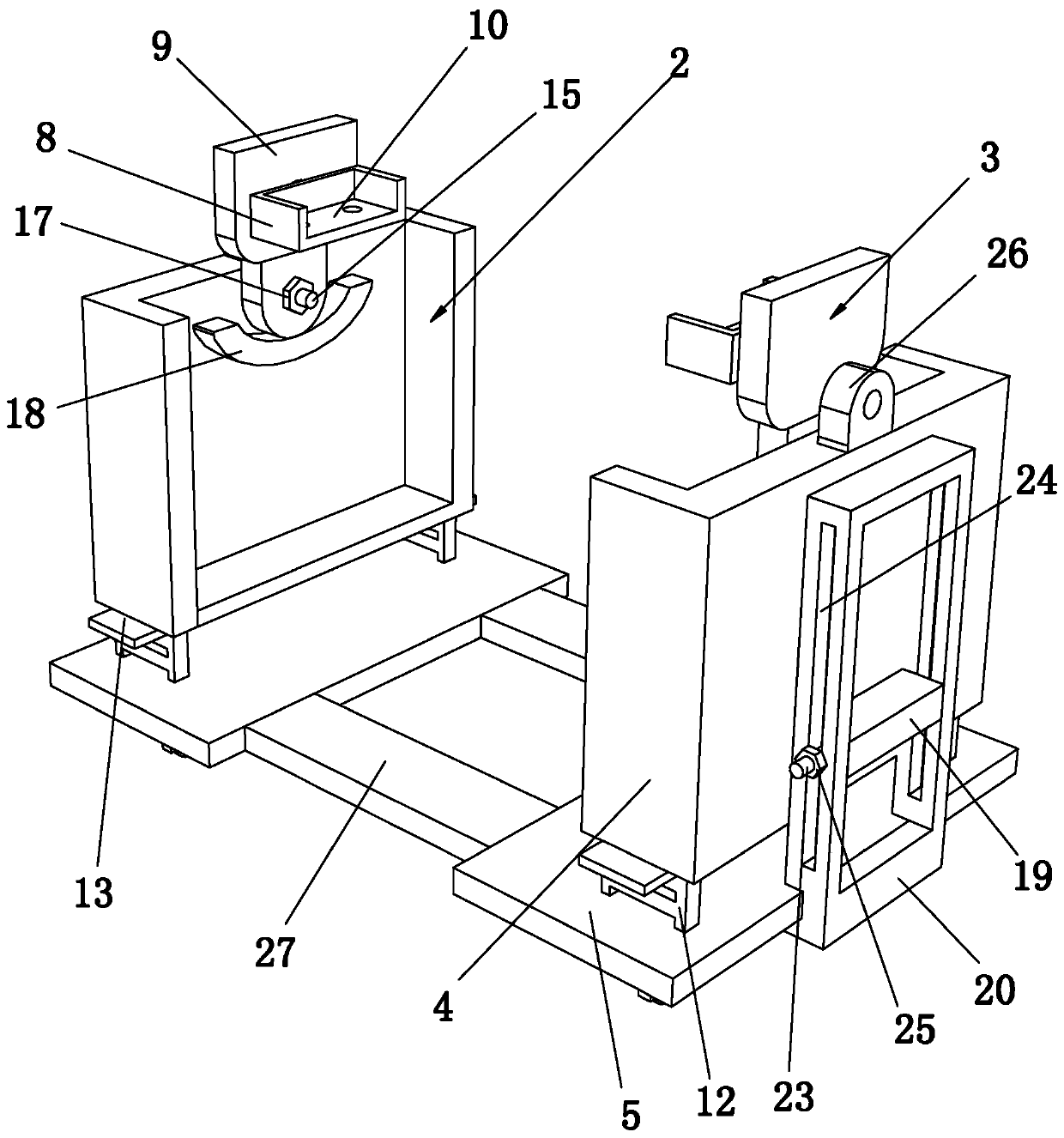

[0042] Such as Figure 1 to Figure 8 As shown, it is a chemical grouting mixing tank with a stable structure of the present invention, including a mixing tank body 1 and a stabilizing frame 2, the mixing tank body 1 is located between the left and right stabilizing frames 2, and the two stabilizing frames 2 The two sides are fixedly connected, the left and right sides of the mixing tank 1 are connected with the installation frame 3, the installation frame 3 is connected with the stable frame 2, the stable frame 2 includes the support frame 4 and the base 5, and the support frame 4 and the base 5 can be adjusted and connected , the left and right bases 5 are fixedly connected by a connecting plate 27, and the bottom surface of the base 5 is provided with a moving roller 6, by which the position of the mixing tank 1 can be adjusted easily, thereby making it easier for the mixing tank 1 Connections with other devices.

[0043] The left and right side walls of the mixing tank bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com