Dust-free recycling pretreatment device for tiles

A pretreatment device and tile technology, applied in grain processing, grinding/polishing safety devices, using liquid separators, etc., can solve problems such as polluting the environment, damaging the health of workers and nearby residents, and affecting product quality. To achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

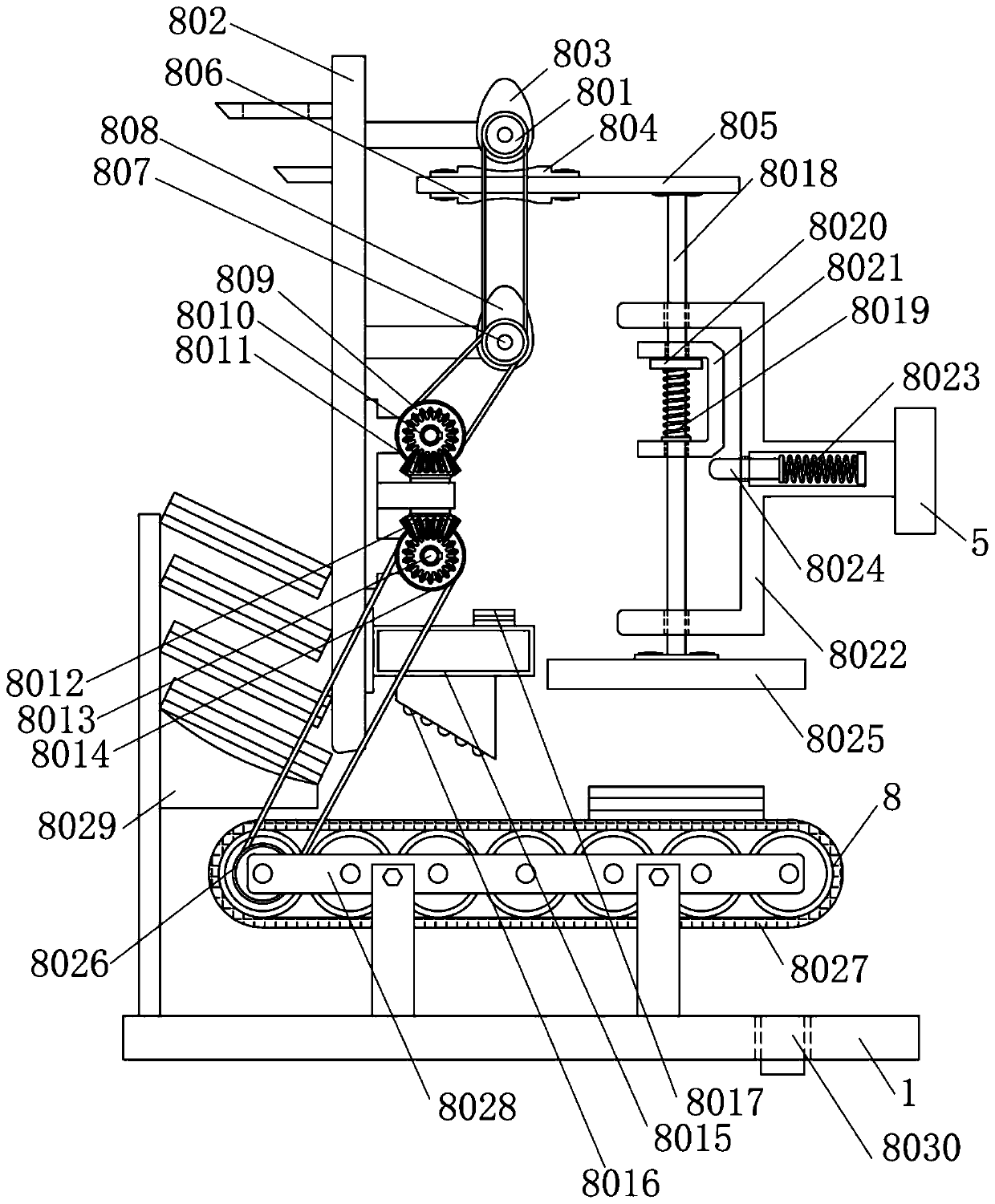

[0026] A tile dust-free recovery pretreatment device, such as Figure 1-6 As shown, it includes a bottom plate 1, a first wheel 2, a second wheel 3, a support frame 4, a first connecting plate 5, an air pump 6, an algae removal mechanism 7, a crushing mechanism 8, a dust removal mechanism 9 and a collection basket 10; the bottom plate 1 The bottom left part is provided with the first wheel 2; the bottom right part of the base plate 1 is provided with the second wheel 3; the top left part of the base plate 1 is welded with the support frame 4; Bolt connection, and the top of the first connecting plate 5 is connected with the support frame 4; the middle right part of the top of the bottom plate 1 is provided with a collection basket 10; the middle right part of the top of the support frame 4 is provided with an air pump 6; the left top of the support frame 4 is provided with alga The removal mechanism 7, and the right top of the algae removal mechanism 7 is connected with the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com