Small dental impression material automatic blending device

An impression material and tooth technology, applied in the medical field, can solve the problems of complexity, inability to import materials into syringes, and many processes, so as to achieve the effect of reducing workload, achieving fixed weight, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

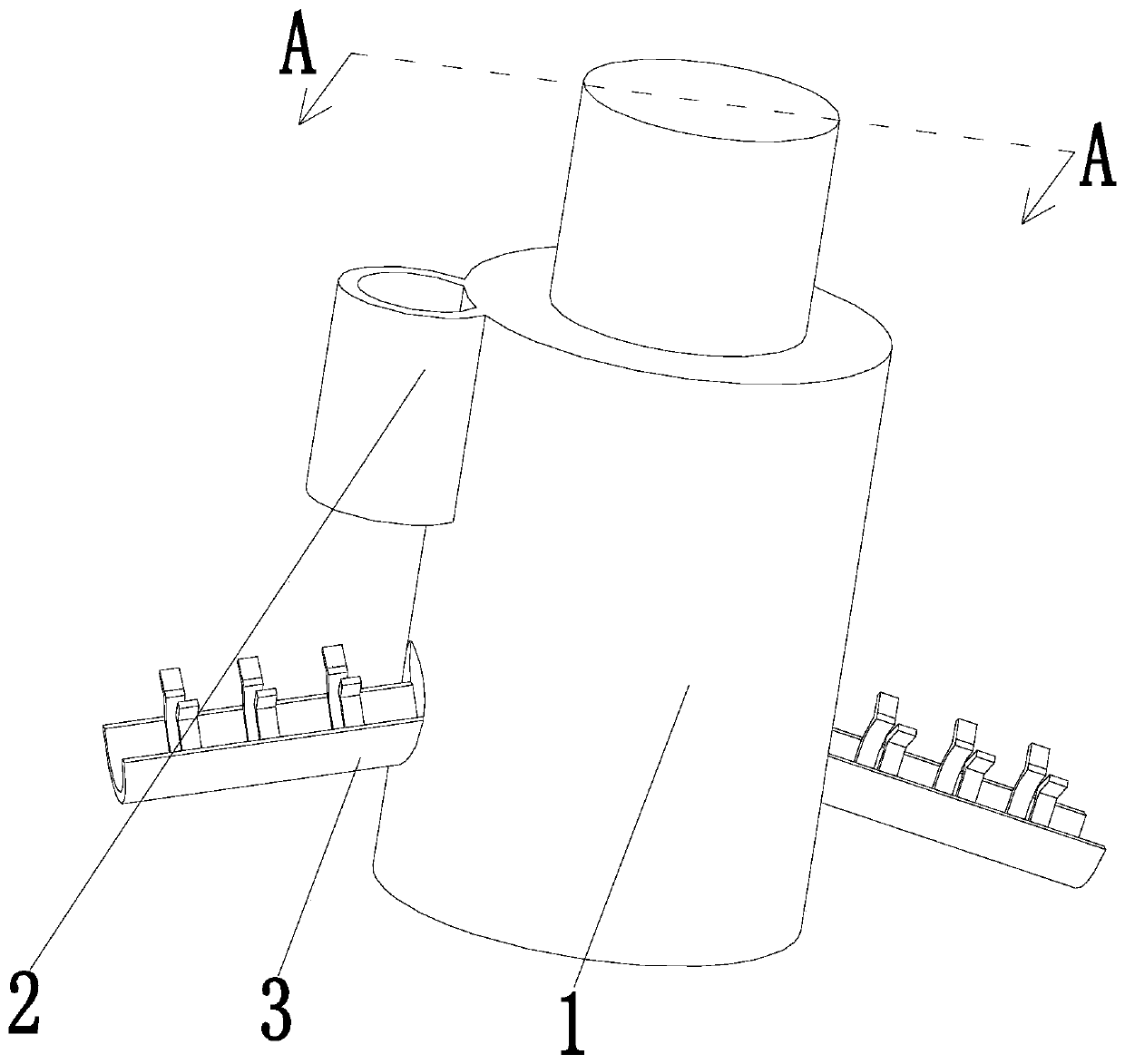

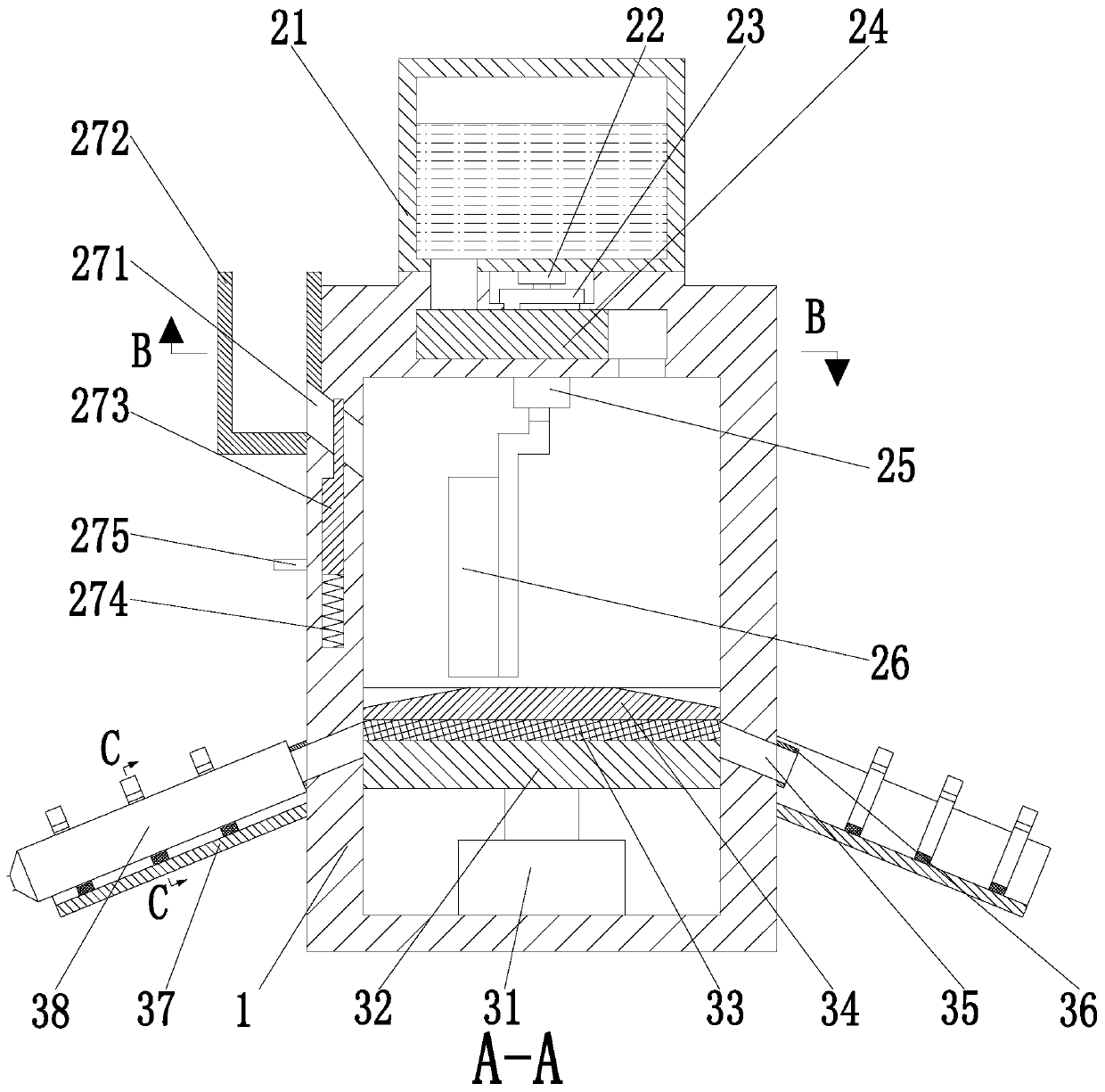

[0025] Such as Figure 1 to Figure 5 As shown, a small-scale dental impression material automatic blending device includes a blending cylinder 1, a mixing unit 2 and a feeding unit 3, the upper end of the blending drum 1 is provided with a mixing unit 2, and the inner wall of the lower end of the blending drum 1 is provided with a lower The material unit 3; the mixing unit 2 mixes the quantitative alginate raw material and water in proportion to form a colloidal impression material, and the unloading unit 3 introduces the prepared colloidal impression material into the impression needle tube 38;

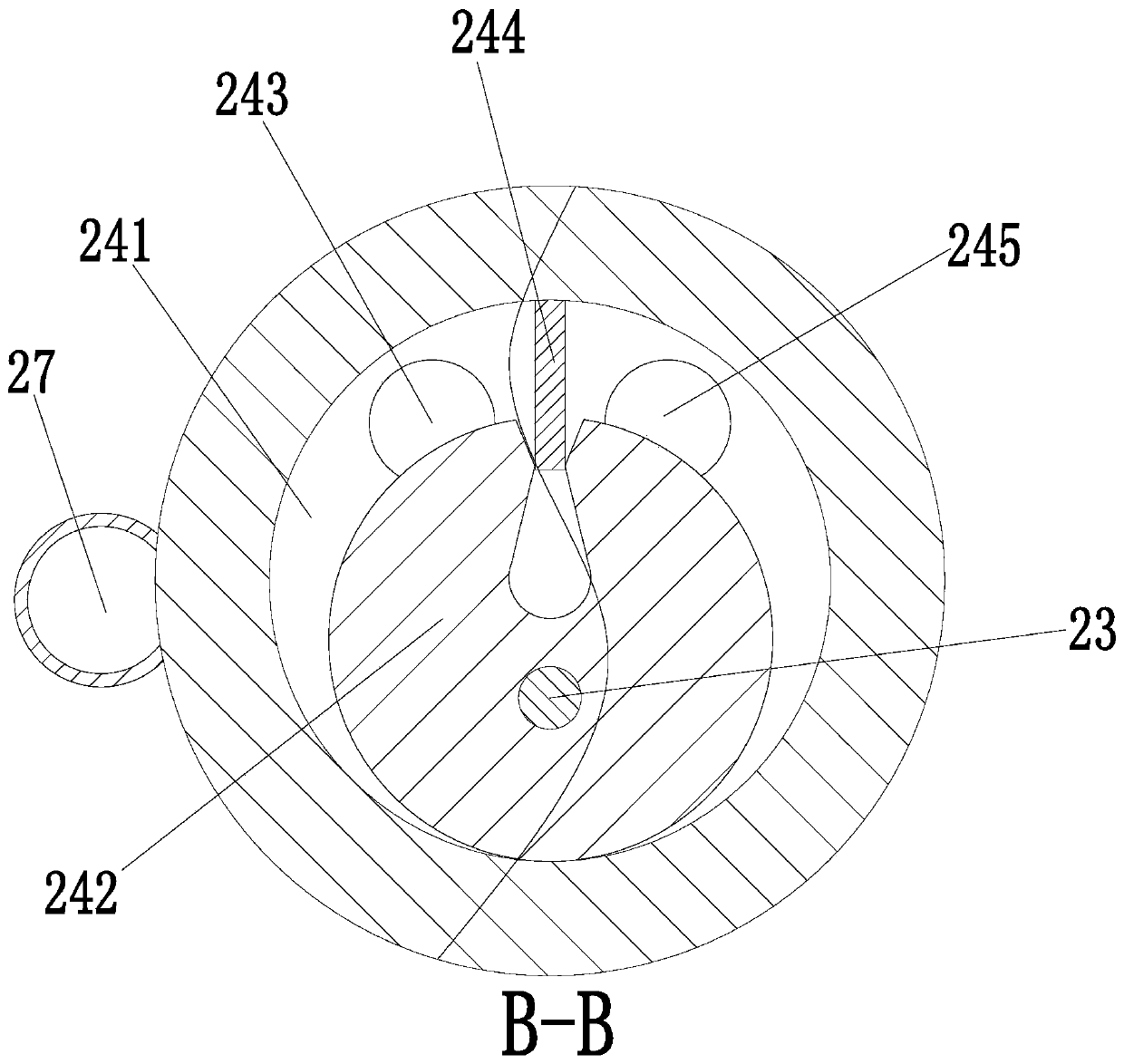

[0026] The mixing unit 2 includes a water storage tank 21, a rotating motor 22, a rotating disk 23, a quantitative mechanism 24, a stirring motor 25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com