Rapid beating device for deicing of vermicelli

A fast and vermicelli technology, applied in the fields of application, food forming, food science, etc., can solve the problems of potential safety hazards and the burden of human hands, and achieve the goals of saving labor consumption, convenient use of equipment, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

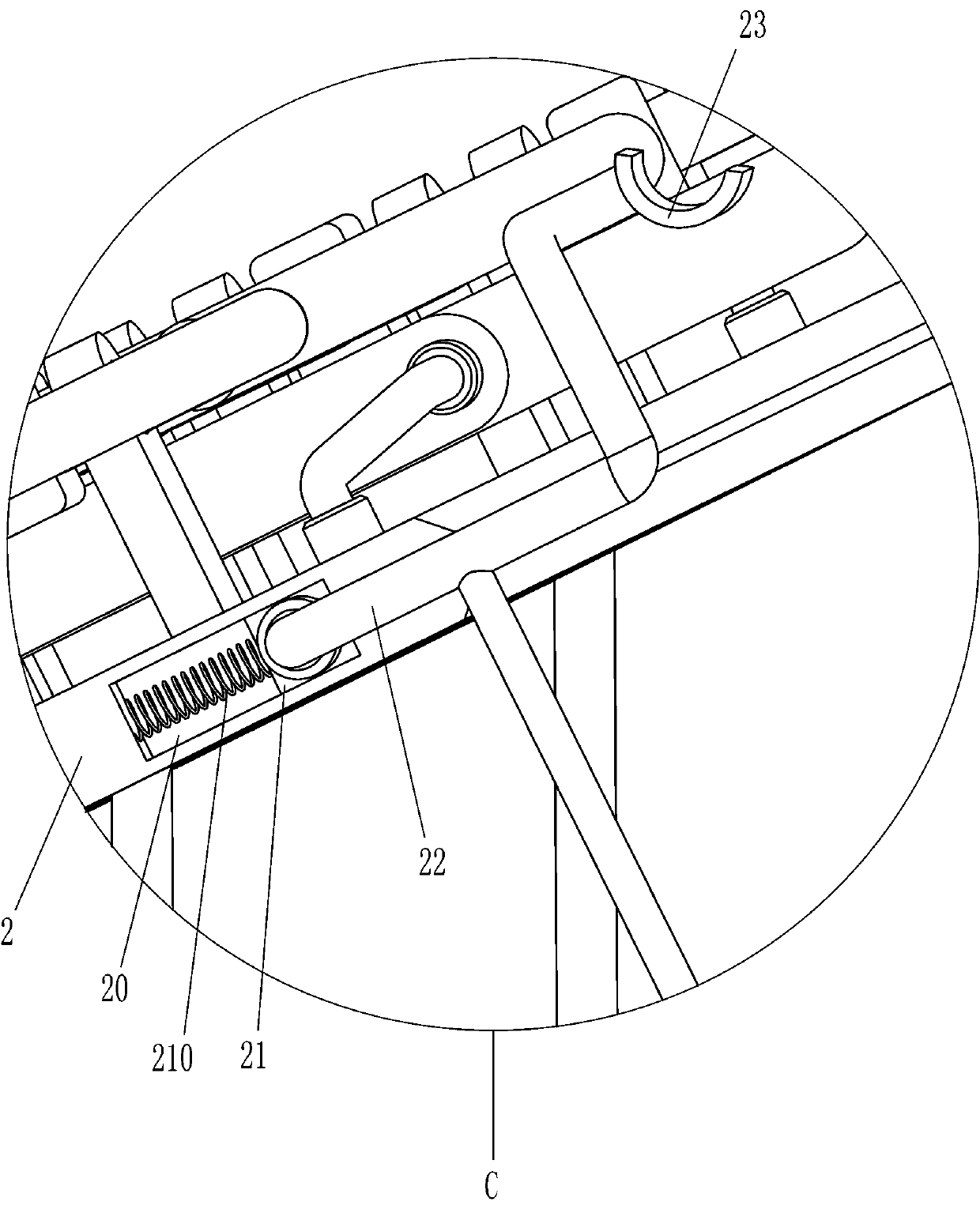

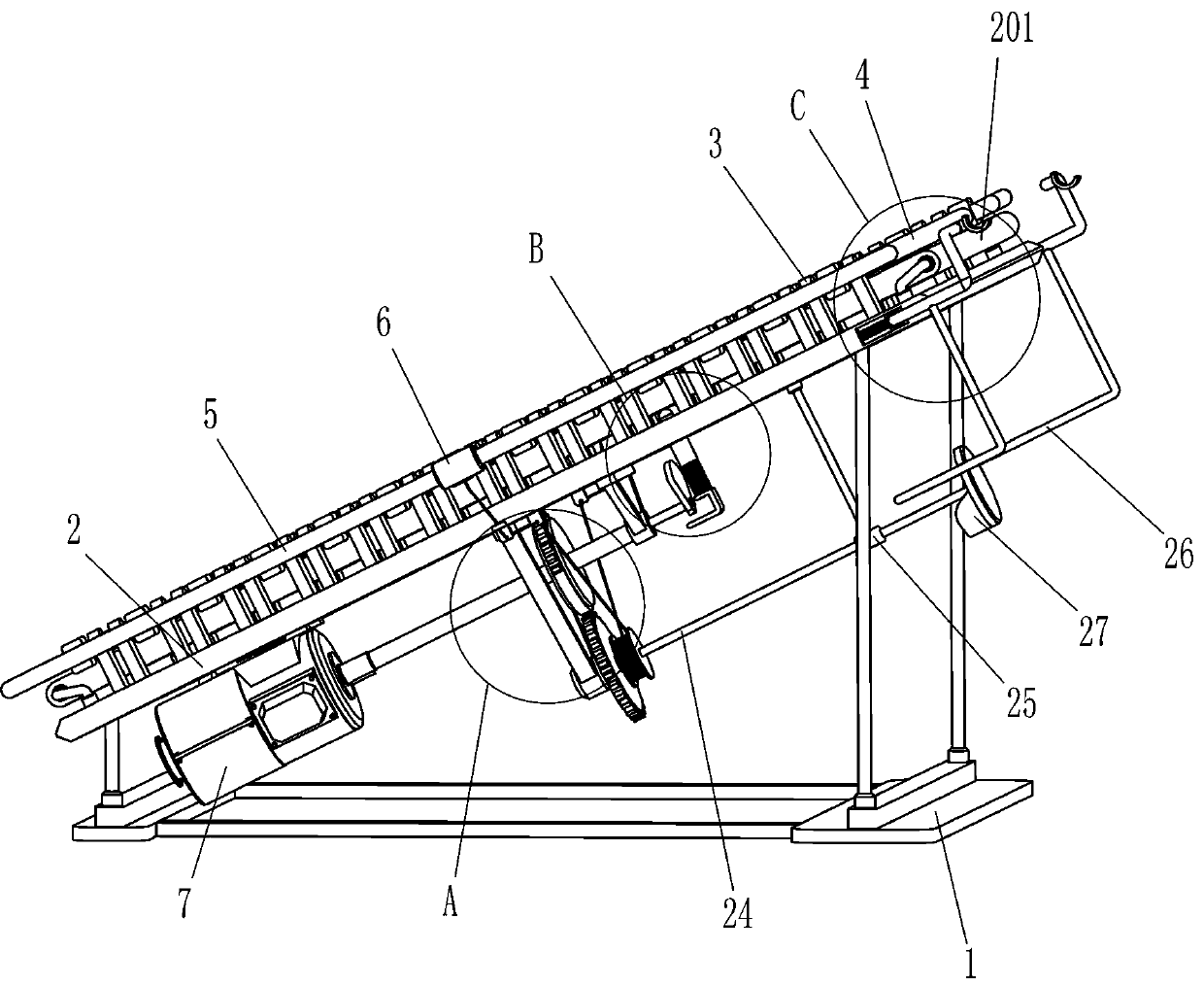

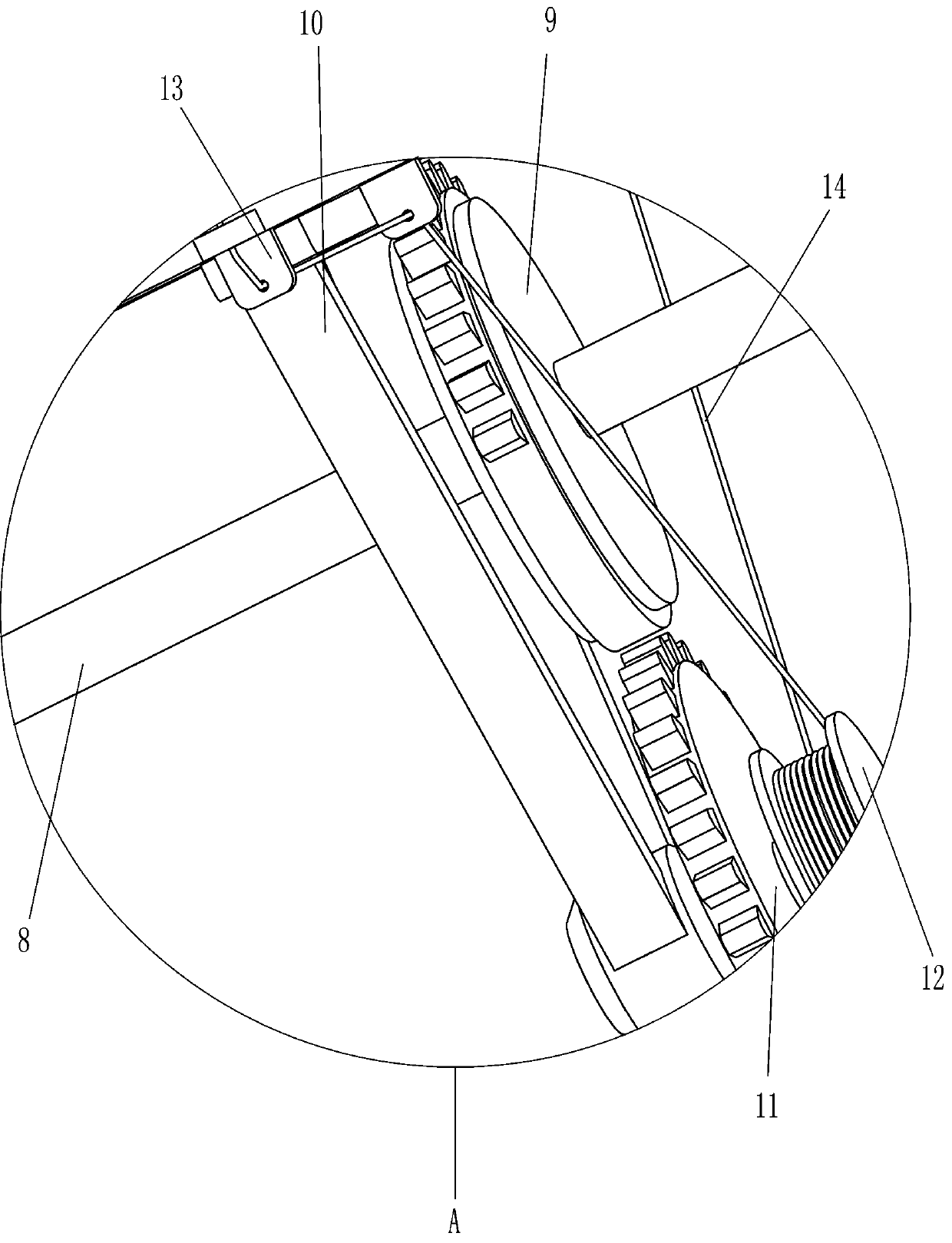

[0021] A quick beating device for vermicelli deicing, such as Figure 1-5 As shown, it includes a frame 1, an inclined plate 2, a backing plate 201, a beating assembly, a driving assembly, a vibrating assembly and a supporting assembly. The top of the frame 1 is connected with the inclined plate 2 through bolts, and the top of the inclined plate 2 is connected with a pad through bolts. Plate 201, the swash plate 2 is provided with a beating assembly that beats by rotating, the bottom of the swash plate 2 is provided with a drive assembly powered by a motor, and the swash plate 2 is provided with a vibrating assembly that vibrates by sliding, the swash plate 2 The support assembly supported by sliding.

[0022] Such as figure 1 and 5 As shown, the beating assembly includes a fixed plate 3, a knock bar 4, a U-shaped bar 5 and a sliding sleeve 6, and two rows of fixed plates 3 are arranged at even intervals on the front and rear sides of the top of the inclined plate 2, and the...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 As shown, it also includes a second rotating rod 24, a guide sleeve 25, a special-shaped rod 26 and a pushing disc 27, the middle part of the right side of the reel 12 is connected with the second rotating rod 24, and the bottom right side of the swash plate 2 is provided with a guide sleeve 25, the guide sleeve 25 is rotationally connected with the second rotating rod 24, the right end of the second rotating rod 24 is provided with a pushing disk 27, and a special-shaped rod 26 is arranged between the support rods 22, and the special-shaped rod 26 cooperates with the pushing disk 27.

[0033]The specific operation method of the above embodiment: when the reel 12 rotates, it drives the second rotating rod 24 to rotate, and then drives the disk 27 to rotate, and when the disk 27 contacts the special-shaped rod 26, pushes the special-shaped rod 26 to move to the left , when the disc 27 is separated from the special-shaped rod 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com