Transformer substation equipment state intelligent identification system based on machine vision

A technology for equipment status and intelligent identification, applied in closed-circuit television systems, registration/indication of machine work, instruments, etc., can solve the problems of low work quality and low work efficiency, and achieve personal safety, improve operation and maintenance level, The effect of improving inspection efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

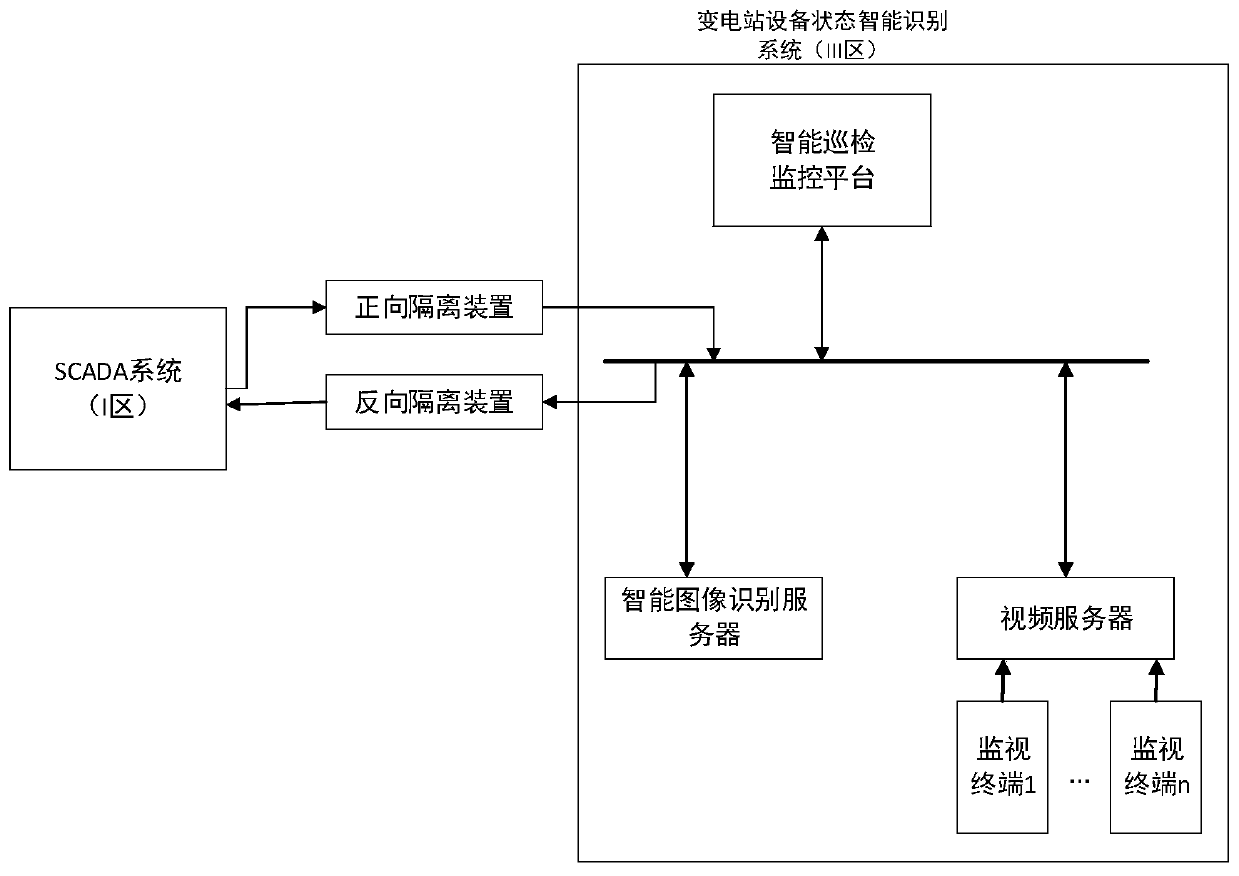

[0046] Such as figure 1As shown, a substation equipment state intelligent recognition system based on machine vision includes: an intelligent inspection monitoring platform, a video server, an intelligent image recognition server, and a monitoring terminal. The intelligent inspection monitoring platform is connected with the intelligent image recognition server, The video server is connected by communication, the monitoring terminal is connected to the video server, the substation equipment state intelligent identification system is connected to the SCADA system through the forward isolation device and the reverse isolation device, and the intelligent inspection monitoring platform is used for inspection video Monitoring and management, the intelligent image recognition server is used to perform image recognition on the switching state of the substation equipment and output the recognition result, the video server is used to control the video monitoring terminal and cache the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com