Drill rod demagnetizing device and method

A technology of degaussing device and drill pipe, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of low degaussing efficiency and poor degaussing effect of degaussing machine, improve degaussing efficiency and drill pipe production efficiency, ensure measurement accuracy, The effect of eliminating residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

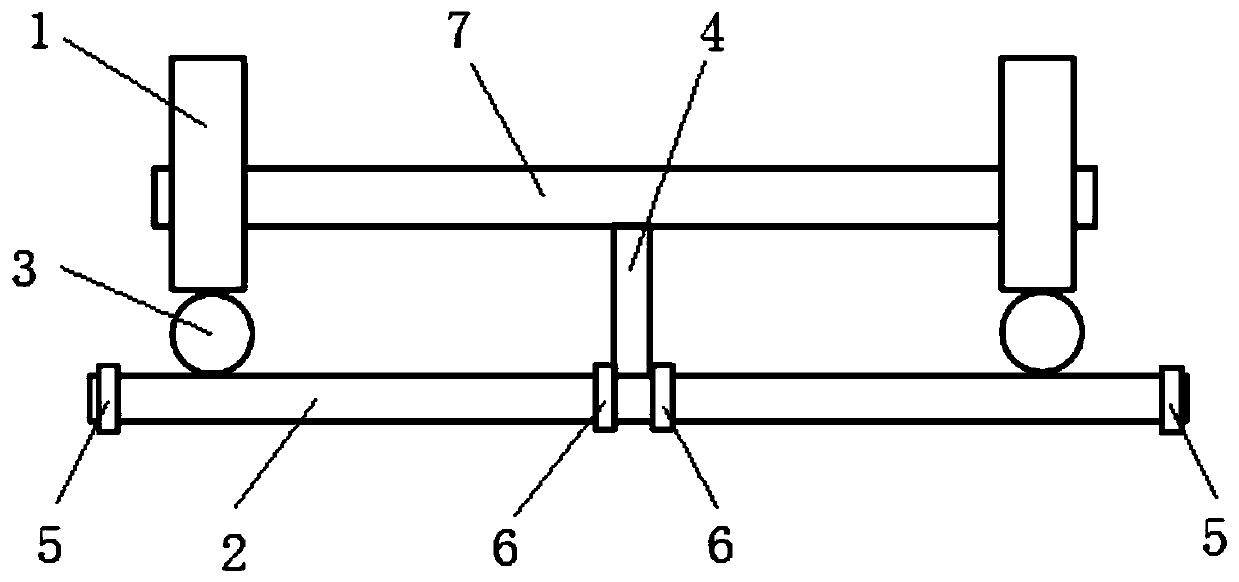

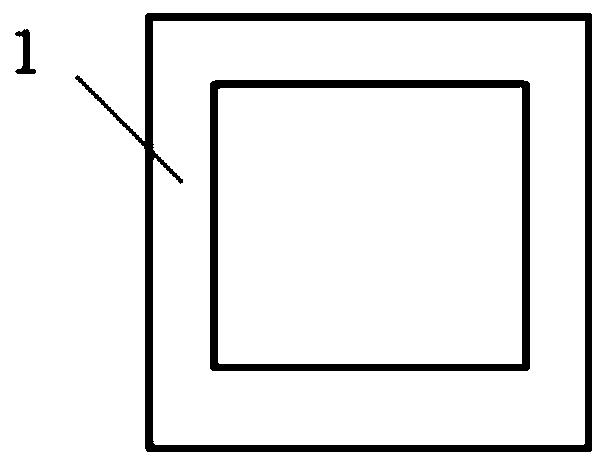

[0026] Such as figure 1 with figure 2 As shown, the present embodiment provides a drill pipe degaussing device, including a transmission mechanism, two synchronous and relatively moving degaussing coils 1 connected to the transmission mechanism, and a controller (not shown) electrically connected to the transmission mechanism and the degaussing coil 1 Shown); The end faces of the two degaussing coils 1 are back-shaped, and their centers are located on the same horizontal line, and the drilling rod 7 is inserted horizontally in the inner cavity, and the middle part of the two degaussing coils 1 is relatively symmetrical to the drilling rod 7.

[0027] The transmission mechanism includes a slide rail 2 arranged horizontally and two pulleys 3 symmetrically arranged on the slide rail 2 and moving relative to the slide rail 2; each pulley 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com