A pipeline leakage inspection method

A pipeline and thermal imaging technology, applied in the fields of information, numerical control, surveying and mapping, and mathematics, can solve problems such as low efficiency, time-consuming and labor-intensive, and potential safety hazards for personnel, and achieve the effect of improving accuracy, improving recognition rate, and eliminating external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Analysis principle of pipeline leakage accident: After the pipeline leaks, the material in the pipe will seep out, pollute the surrounding environment, and cause the color of the surrounding environment to change; the seepage will affect the change of the temperature of the surrounding environment. According to the above two points, the color difference change and the temperature difference change around the pipeline are combined for comparative analysis to obtain the information of the accident location area.

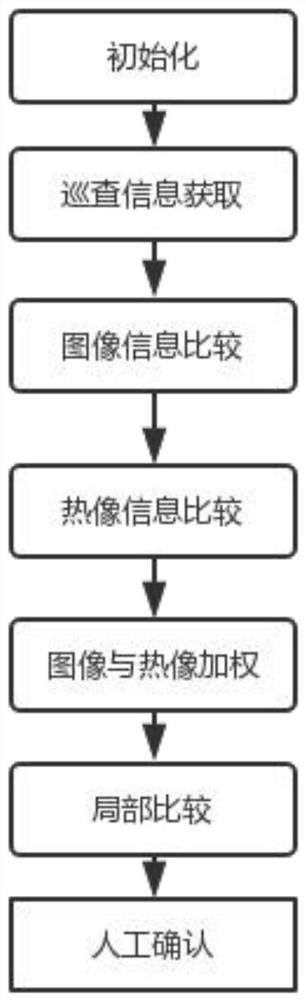

[0045] see figure 1 with figure 2 , a pipeline leakage inspection method, comprising the following steps:

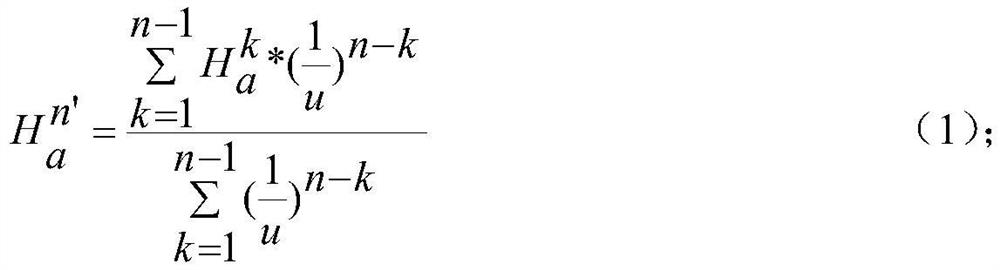

[0046] Step 1: Initialization; determine the pipeline path, obtain the image range and accuracy according to the camera and thermal imager, and carry out initialization information collection along the pipeline path; The object fits the image to a fixed coordinate system; obtains the image information and thermal image information of each position area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com