Multifunctional roadway repair machine and construction method thereof

A multi-functional roadway and repairing machine technology, which is applied in tunnels, earth-moving drilling, earthmoving machines/shovels, etc. The effect of work efficiency, wide application range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

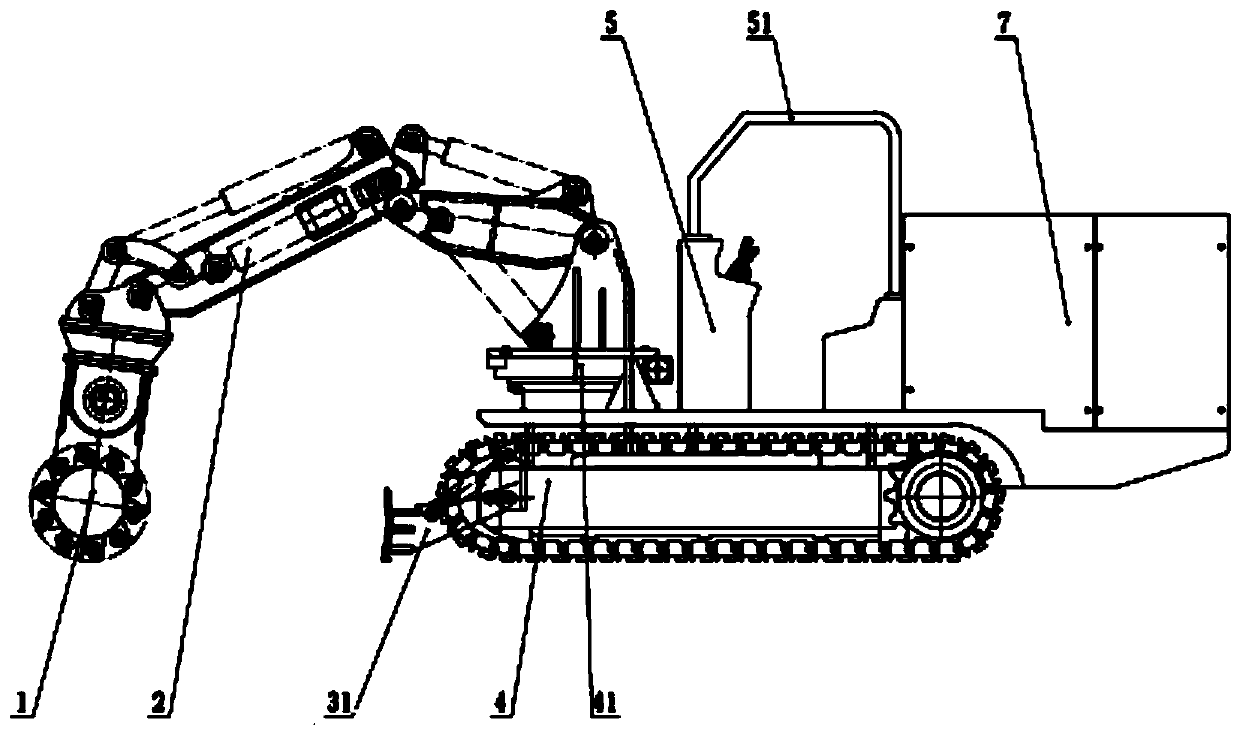

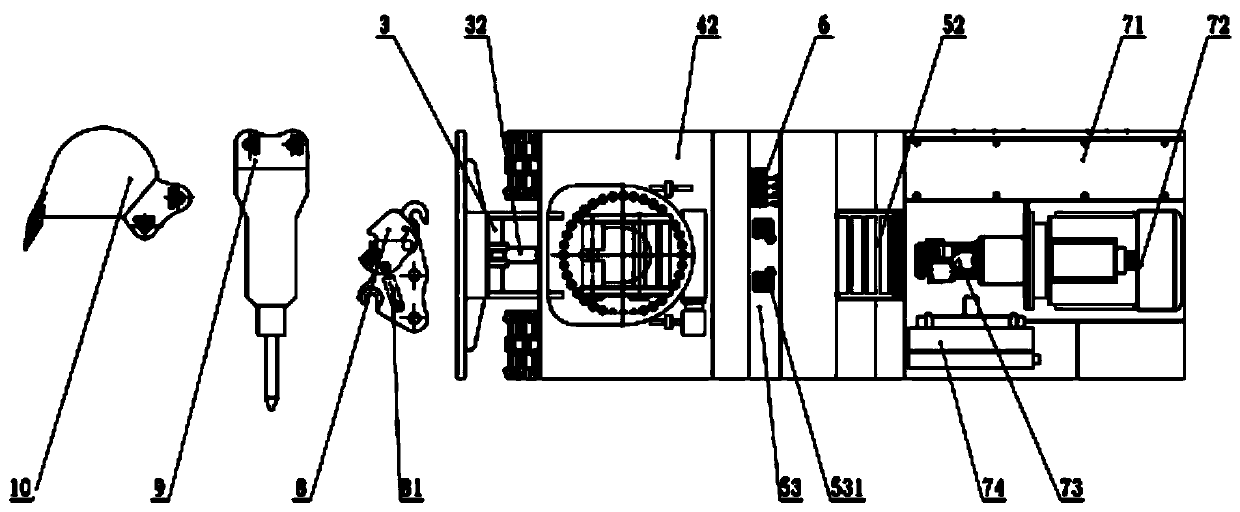

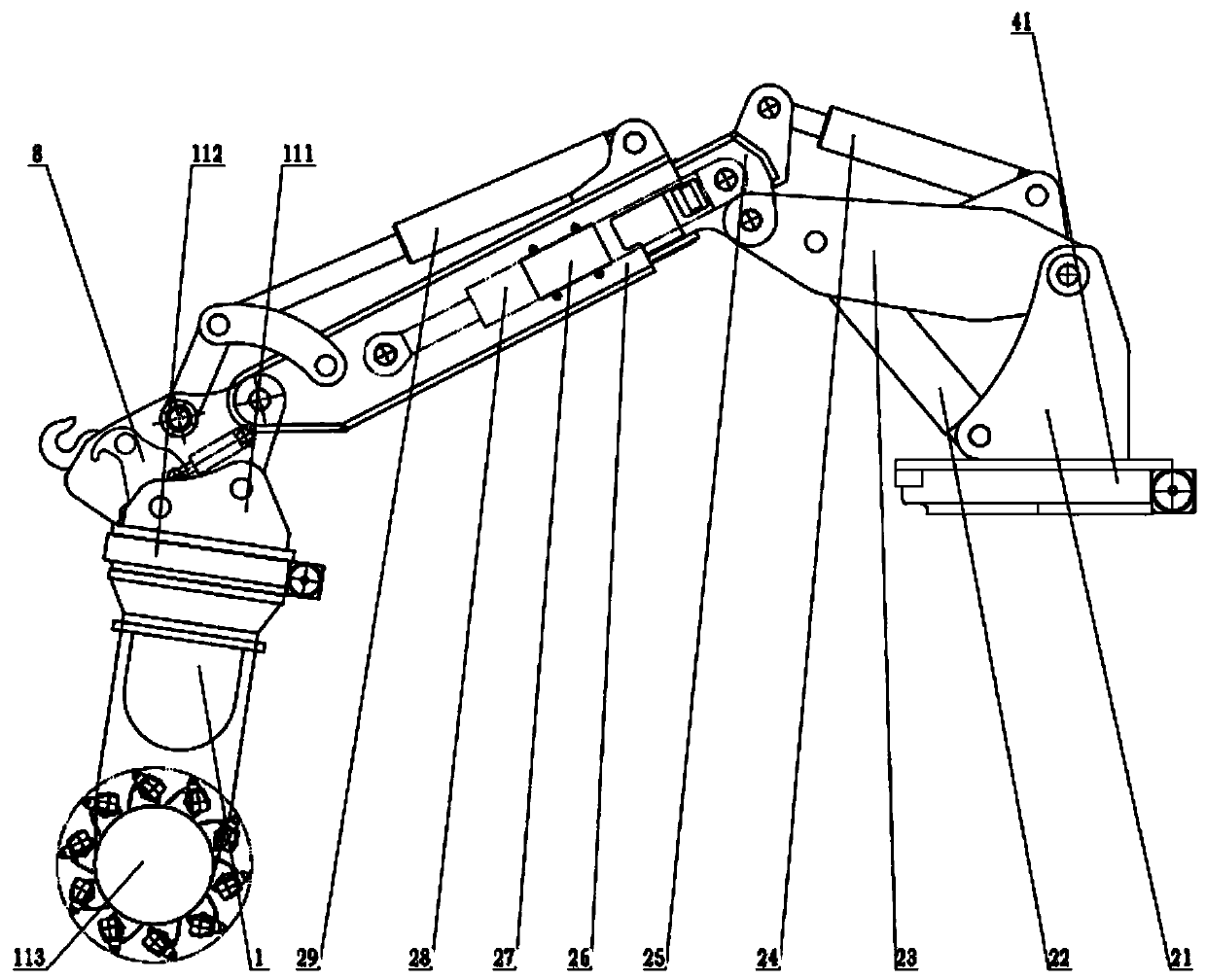

[0040] Refer to attached figure 1 , figure 2As shown, it is an implementation example of the present invention. The present invention provides a multifunctional roadway repair machine, including a milling operation part 1, a multifunctional working arm 2, a liftable push plate device 3, a chassis 4, a manipulation part 5 and The power assembly 7, wherein the liftable push plate device 3 is hinged at the lower part of the front end of the chassis 4, which can be used to level the roadway and support the whole machine; the chassis 4 is used to connect the remaining parts of the whole machine on the one hand, and bear the work of the whole machine on the other hand The impact of various lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com