Single-layer blanking device for high pressure forming machine

A high-pressure molding machine and single-layer technology, which is applied in the direction of ceramic molding machines, unloading devices, manufacturing tools, etc., can solve the problem of affecting the telescopic efficiency and accuracy of the blanking trolley, the sinking of the end of the blanking trolley, and its own weight. problems, to achieve the effect of reducing cost input, avoiding wear and tear of sliding parts, and reducing its own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] See attached Figure 1-5 The technical solution disclosed in the present invention is to improve the traditional double-layer preform frame and sliding assembly into a single-layer preform frame and slide assembly connection.

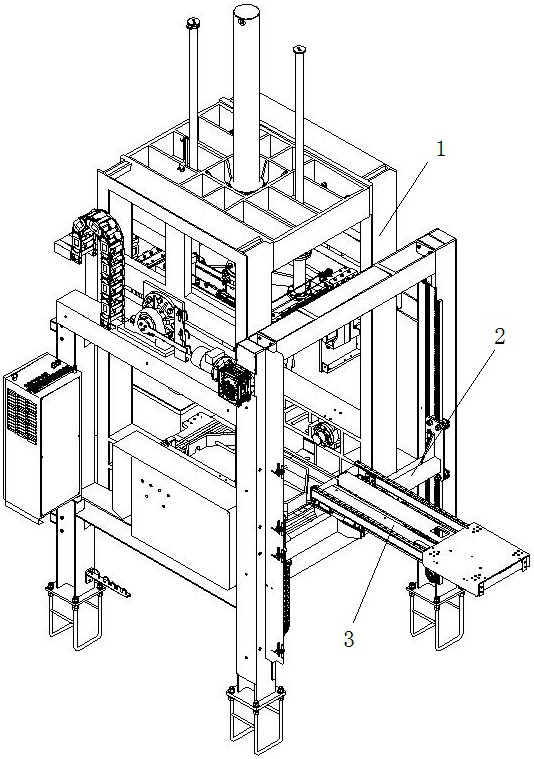

[0024] See figure 1 , this high-pressure molding machine uses a single-layer blanking device to be arranged on the molding machine frame 1, and the up and down movement is controlled by the lifting mechanism, and it is vertically arranged with the lifting mechanism beam 2, including the combination of the blanking trolley and the blanking platform.

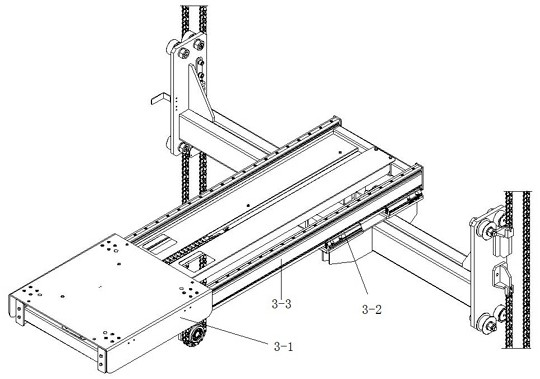

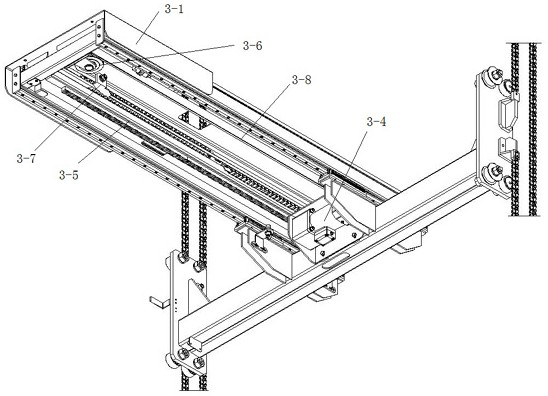

[0025] See Figure 2-3 , The blank trolley combination includes a fixed slide rail 3-2, a blank trolley frame 3-3, a moving slide rail 3-10 and a drive mechanism. The fixed slide rail is fixedly installed on the beam of the lifting mechanism; the frame of the billet trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com