Integrated furrowing and fertilizing machine capable of facilitating safe use

An all-in-one, fertilizer applicator technology, applied in the directions of fertilizer applicator, excavation/covering of trenches, application, etc., can solve the problems that the machine cannot complete trenching, fertilizer application and soil covering operations at one time, and the fertilizer efficiency is low, so as to achieve convenient and rapid advancement. work, reduce the cost of machinery and equipment, and improve the efficiency of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

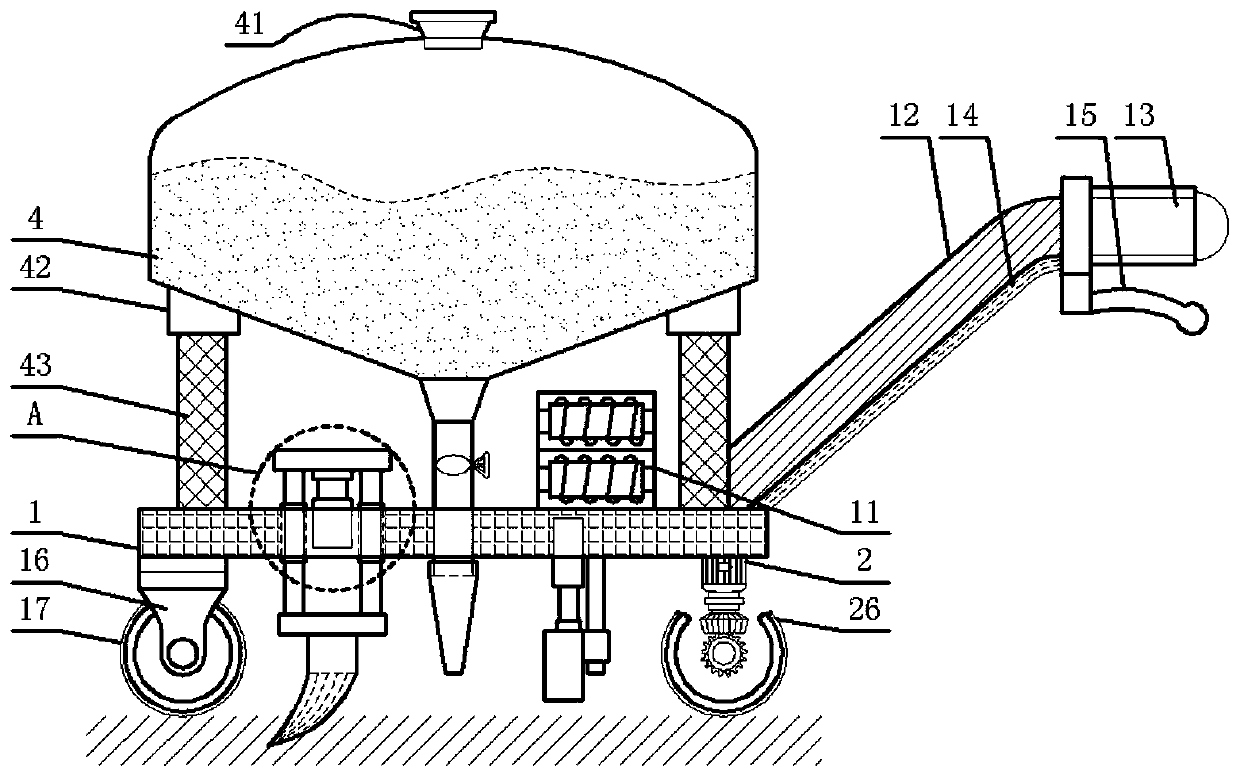

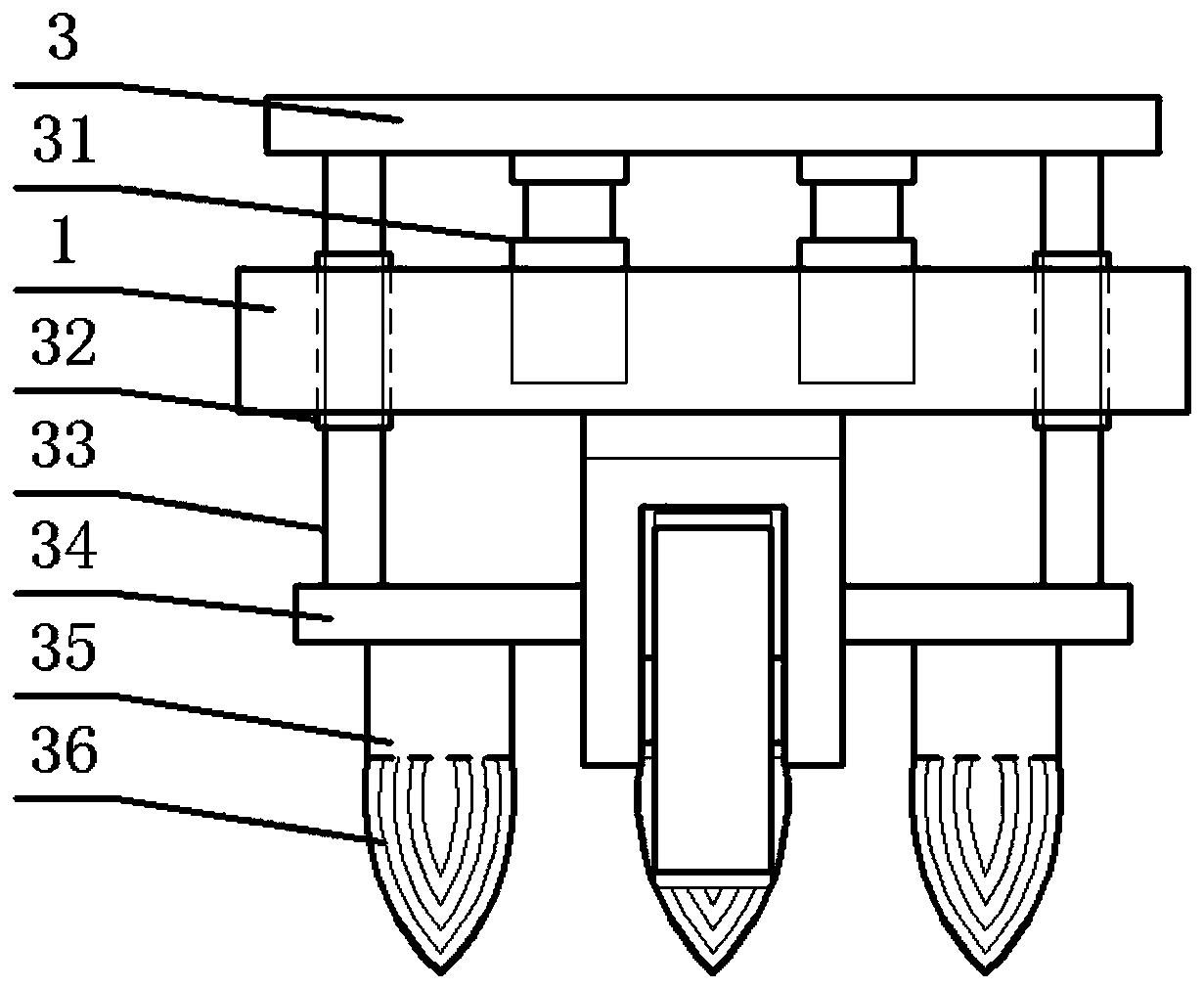

[0024] Embodiment 1: In order to solve the problem that the ditching, fertilization and soil covering operations cannot be completed at one time in the narrow space of the orchard, reduce the cost of equipment and improve the efficiency of fertilization, this embodiment proposes an integrated ditching and fertilizing machine that is easy to use and safe , see Figure 1-5 , including a base plate 1, the base plate 1 is a rectangular plate placed horizontally and horizontally, the middle part of the front end of the bottom surface of the base plate 1 is provided with a universal wheel bracket 16 with the opening facing downward, and the opening of the universal wheel bracket 16 passes through the wheel shaft and The universal wheel 17 is movable and hinged, and the universal wheel 17 can turn conveniently; the front end of the bottom surface of the base plate 1 is provided with a ditching mechanism behind the universal wheel 17; the storage box 4 is provided directly above the to...

Embodiment 2

[0030] Embodiment 2: when the present invention is specifically used, its operating steps are as follows:

[0031] Step 1, hold the handle 13 and push the push rod 12, and the control rod 15 controls the battery pack 11 to turn on the power supply through the control line 14;

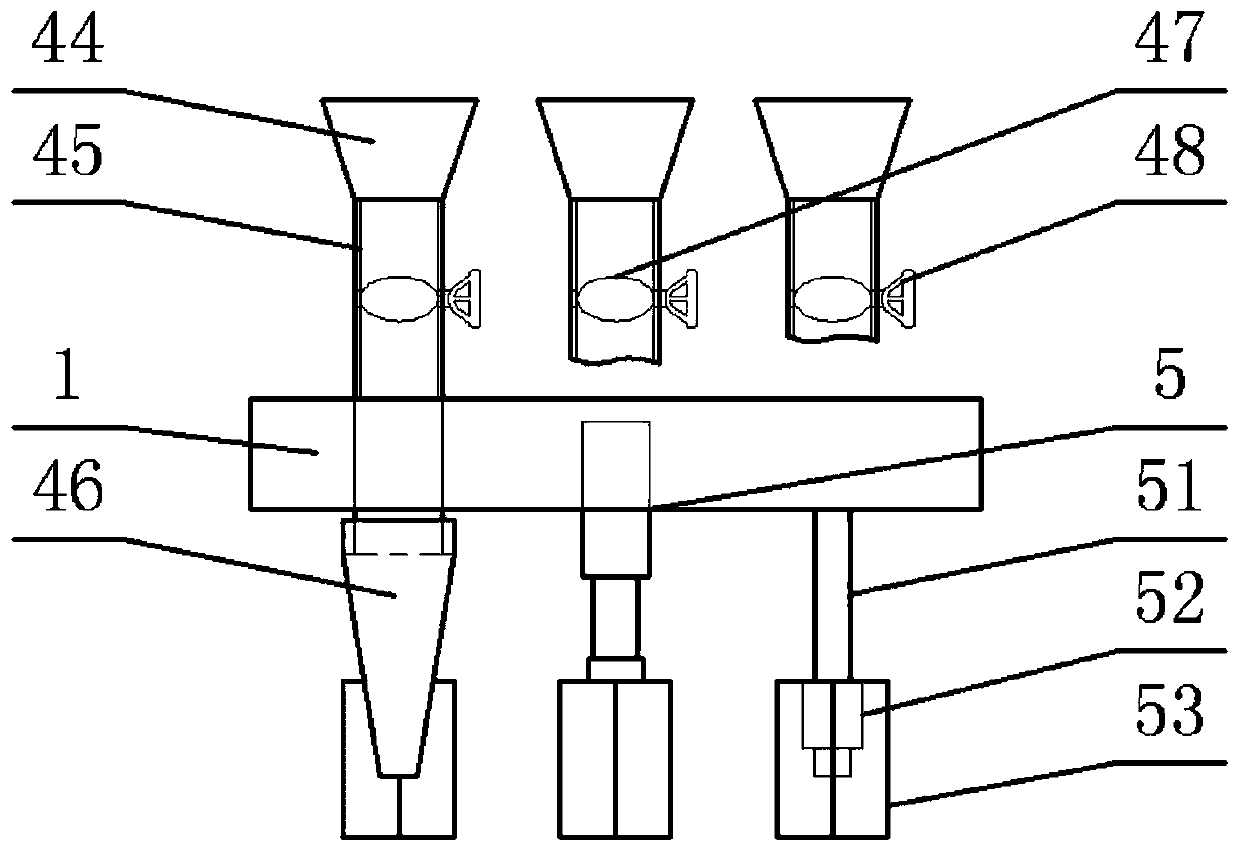

[0032] Step 2, the worker enters the fertilizer into the discharge box 4 through the feed cylinder 41, and then enters the fertilizer application cylinder 45 through the short conical cylinder 44;

[0033] Step 3, control the rotation of the motor shaft of the motor 2, drive the driving gear 24 to rotate synchronously through the coupling, and then mesh to drive the driven gear 25 and the drive shaft 23 to rotate, and then drive the driving wheel 26 to cooperate with the use of the universal wheel 17 to push the bottom plate 1 move forward;

[0034] Step 4, control the first electric push cylinder 31 to drive the ditching top plate 3 to descend through the first connecting block, and then drive the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com