A power module terminal

A power module terminal and end face technology, which is applied in the direction of welding/welding connection, etc., can solve the problems of low terminal strength and low vibration resistance, and achieve high structural rigidity, good vibration resistance, and improved vibration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

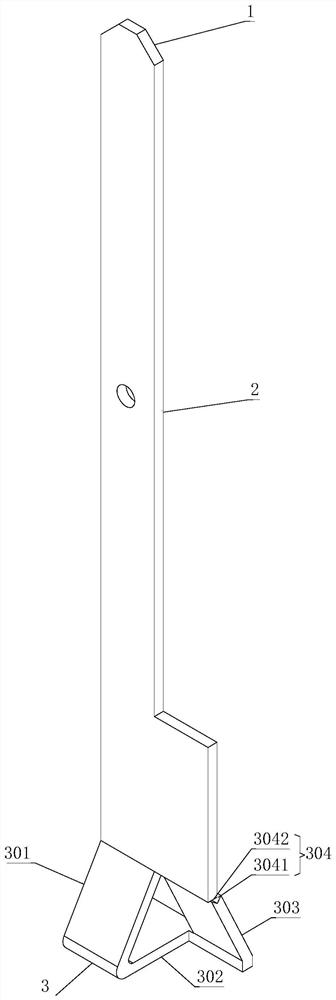

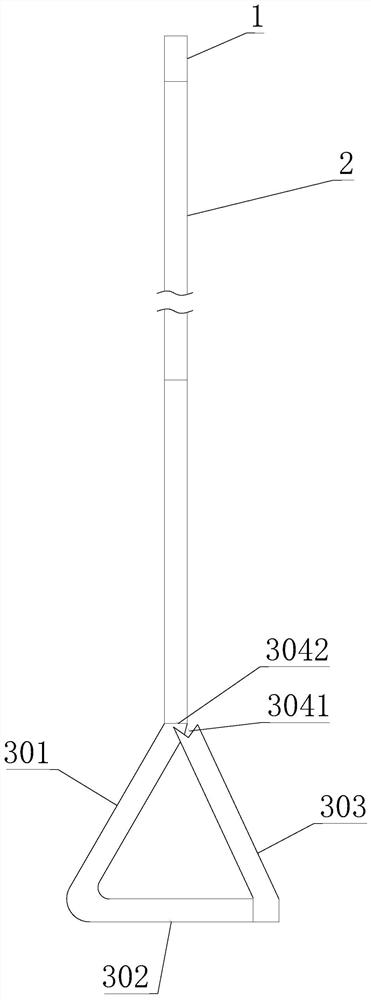

[0029] Such as Figure 1 to Figure 3 As shown, the power module terminal of this embodiment includes a head 1, a middle part 2 and a welding structure 3 connected in sequence; wherein the welding structure 3 includes a supporting part 301, a buffer part 303 and a welding part 302, and one end of the supporting part 301 is connected to The middle part 2 is connected, the other end is connected to one end of the welding part 302, the other end of the welding part 302 is connected to one end of the buffer part 303, and a notch structure 304 is arranged between the other end of the buffer part 303 and the middle part 2, that is, in An opening is formed between the buffer part 303 and the middle part 2; the supporting part 301, the buffer part 303 and the welding part 302 of the welding structure 3 are triangular in shape as a whole. When the terminal head 1 is under pressure, the head 1 and the middle part 2 will be compressed toward the side of the welding structure 3. Since an o...

Embodiment 2

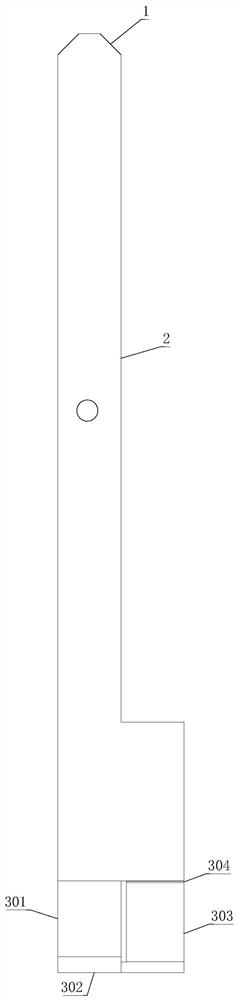

[0035] Such as Figure 4~6 As shown, the difference between this embodiment and Embodiment 1 is only the difference of the seam structure 304. In this embodiment, the seam structure 304 includes a seam surface 3042, and the seam surface 3042 is located at the end of the middle part 2. A limiting step 3043 is formed between the mouth surface 3042 and the middle part 2, and the mouth surface 3042 matches the end surface of the other end of the buffer part 303. Similarly, when the terminal head 1 is under pressure, the end of the buffer part 303 is It fits with the notch surface 3042 to maximize the contact area and ensure the reliability of compression resistance, while the limit step 3043 ensures the limit deformation distance. Of course, the notch surface 3042 can also be located at the end of the buffer portion 303 , a limiting step 3043 is formed between the notch surface 3042 and the buffer portion 303 , and the notch surface 3042 matches the end surface of the middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com