Bearing steel ball test bench

A bearing steel ball and test bench technology, which is used in mechanical bearing testing, testing wear resistance, measuring devices, etc., can solve problems such as inability to determine whether there are defects in bearing materials, uncertainty of rolling element trajectory, and rolling element damage. , to achieve the effect of increasing the number of samples and randomness, requiring less assembly space, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 of the bearing steel ball test rig in the present invention: the bearing steel ball test rig in the present invention is used for testing and researching the fatigue life of the bearing steel ball as the rolling element in the bearing, mainly to make the material to be tested into bearing steel The ball simulates the long-term motion of bearing steel balls between the bearing inner ring and bearing outer ring, providing data support for the research of bearing steel balls.

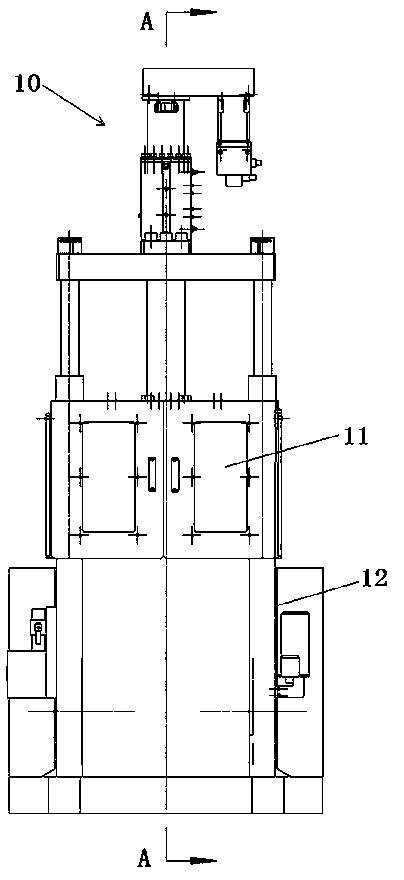

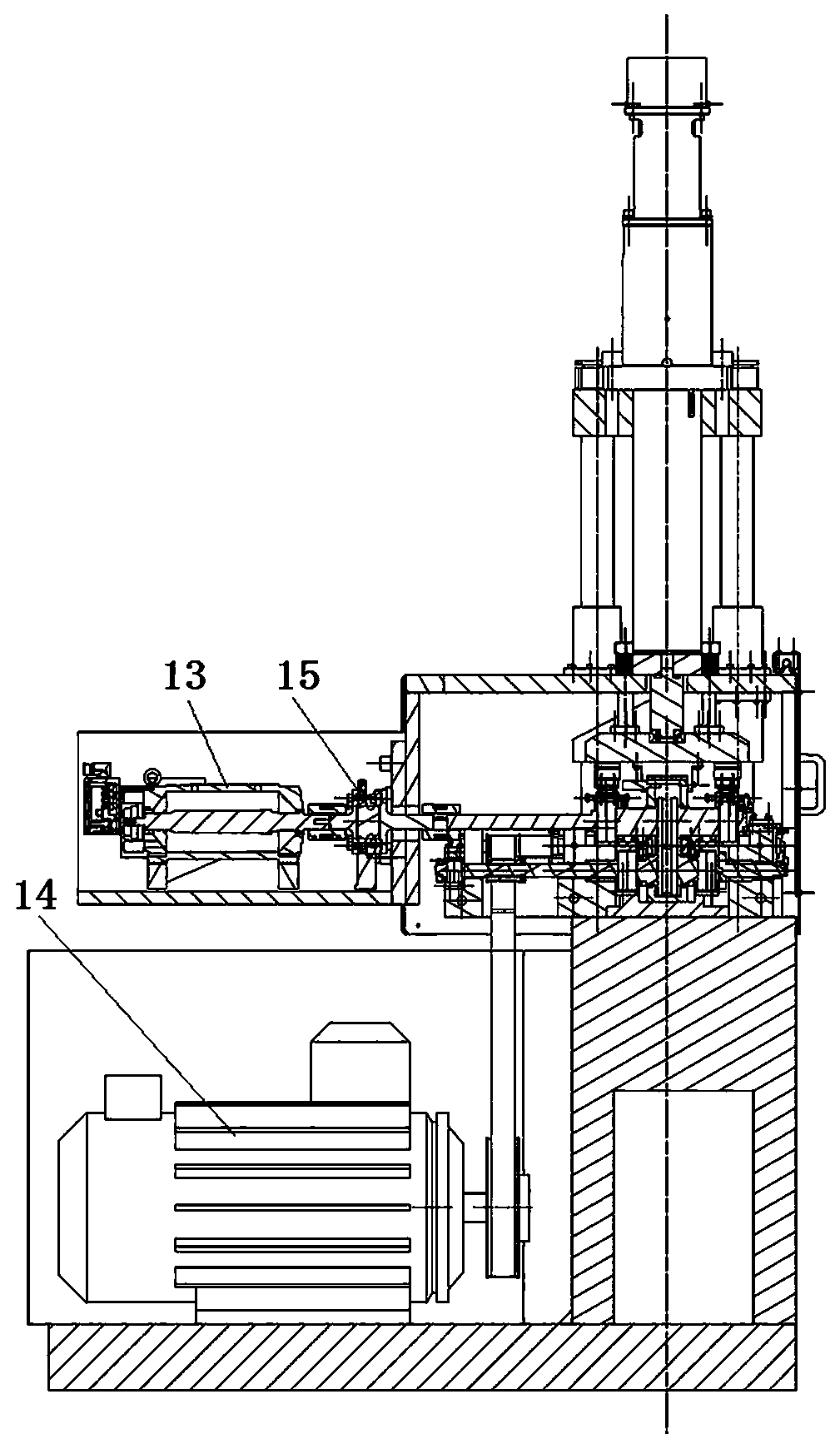

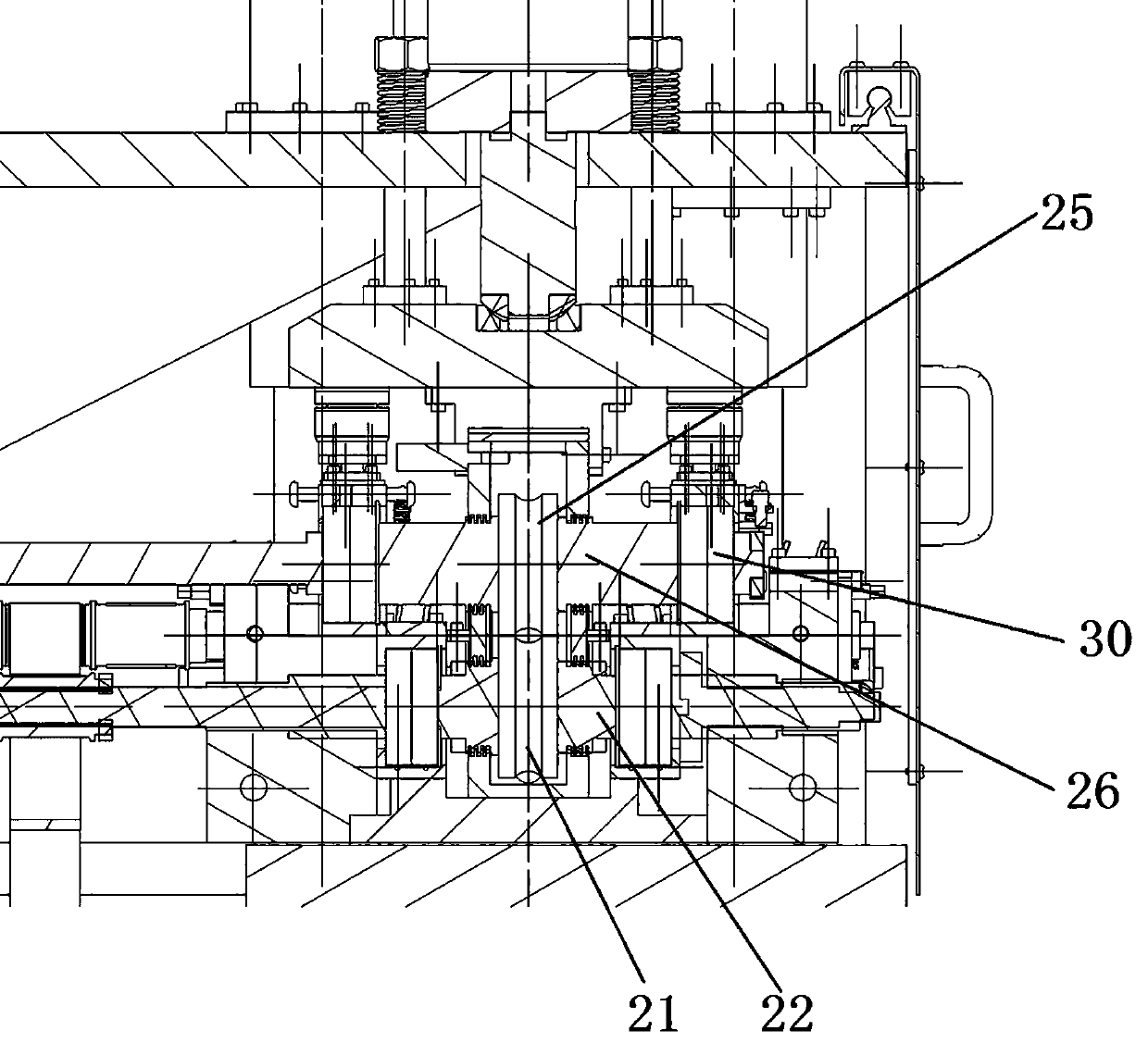

[0052] Such as figure 1 and figure 2 As shown, the bearing steel ball test bench 10 includes a frame 12 on which components for different functions are arranged. The upper part of the frame 12 is arranged with a test chamber 11, in which a friction pair for frictional cooperation with the bearing steel ball to be tested is arranged. Corresponding to the friction wheel on the wheel shaft, the three rotating wheels are further divided into a driving wheel and a driven wheel according t...

Embodiment 2

[0065] Embodiment 2 of the bearing steel ball test bench in the present invention: the difference from the above embodiment is that the frame in this embodiment is provided with a bearing seat for supporting the driving shaft, and the driving shaft is connected to the bearing in the bearing seat through screws. The inner ring is connected, and there are multiple screw holes on the drive shaft for the operator to adjust the installation position of the drive shaft and the bearing. The operator can move the driving wheel in the trial wheel set axially by adjusting the installation position of the driving shaft. In other embodiments, all driving wheels and driven wheels in a test wheel set can adopt the method for adjusting the axial position provided in embodiment 1 and embodiment 2; it can also be only driving wheels or one of the driving wheels and The axial position of a driven wheel is adjustable.

Embodiment 3

[0066] Embodiment 3 of the bearing steel ball test bench in the present invention: the difference from the above embodiment is that the axial position of the driven shaft as the wheel shaft in this embodiment cannot be adjusted, and the operator can use tools to directly adjust the center of the driven wheel. The friction wheel exerts an axial force, so that the friction wheel moves a small distance along the axial direction of the wheel shaft, thereby realizing the adjustment of the axial position of the friction wheel. This solution can also be used to adjust the installation position of the driving wheel and the driving shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com