A slow-release, resistance-increasing, pressure-yielding bolt and method

A technology of yielding bolts and slow release, which is applied in the installation of bolts, earthwork drilling, construction, etc., and can solve the problems that are not conducive to the stability of the overall structure, and the impact and disturbance of the bolt-rock complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

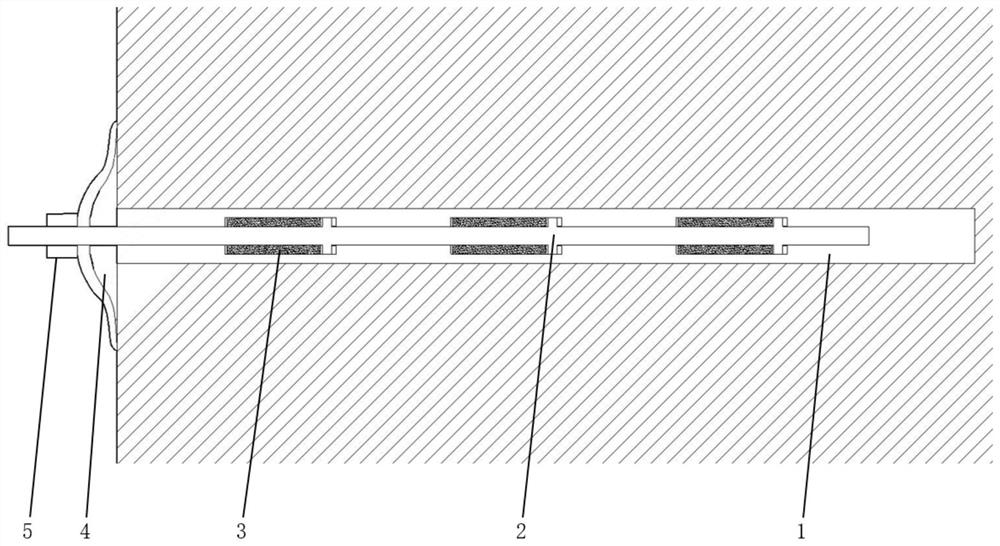

[0026] A slow-release and resistance-increasing pressure bolt comprises a sleeve 1, wherein the sleeve 1 has an inner cavity along the direction of its own axis, and one end of the sleeve 1 is blocked; A shaft rod 2 is passed through, one end of the shaft rod 2 extends into the inner cavity of the sleeve 1 , and the other end is provided with a connecting piece for connecting the rock wall.

[0027] The inner cavity of the sleeve 1 is provided with a gas chamber 3, and the set position of the shaft rod 2 is provided with a piston, so that the gas chamber 3, the shaft rod 2 and the piston are enclosed to form a closed gas space; Compressed gas can be injected into the gas space, and the compressed gas is used to provide resistance when the shaft rod 2 slides away from the sleeve 1 . The piston can slide along the axial direction of the shaft rod 2 to realize the compression or expansion of the gas in the compression space.

[0028] In this embodiment, in order to realize the i...

Embodiment 2

[0040] The present embodiment provides a method for using a slow-release, resistance-increasing, and pressure-resisting anchor, including the following steps:

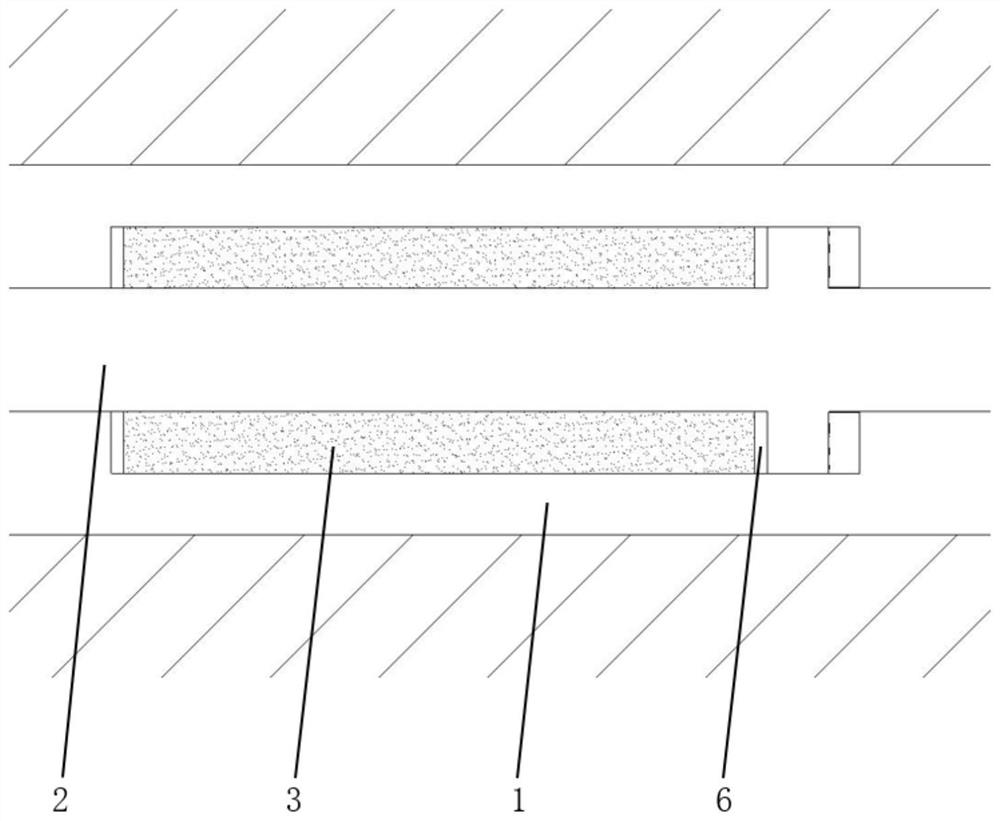

[0041] Use commercial drilling equipment to drill holes on the surface of the rock and soil, the depth of the hole is the same as the length of the sleeve 1, carefully clear the hole and install the anchoring agent in the anchor hole;

[0042] Insert the rod structure composed of sleeve 1, shaft 2 and rubber gasket 6 into the anchor hole, the closed end of sleeve 1 faces into the hole, the open end of sleeve 1 is flush with the rock and soil surface, and the shaft rod 2 part of the length is exposed outside the rock and soil surface;

[0043] Set the anchor plate 4 on the exposed section of the shaft rod 2, with the convex side facing the outside of the rock mass;

[0044] Install the bolt 5 at the top of the shaft 2 and tighten it, and press the anchor plate 4 to the surface of the rock and soil mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com