Hoisting method and system of fabricated building monoblock peripheral component

A technology of peripheral components and hoisting methods, which is applied in the direction of building construction, construction, and building material processing, etc., to achieve the effects of reasonable design, high degree of automation, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] A system for hoisting peripheral components of a prefabricated building block, including a vertical steel frame 200 , a vertical transport device 300 and a transport trolley 400 .

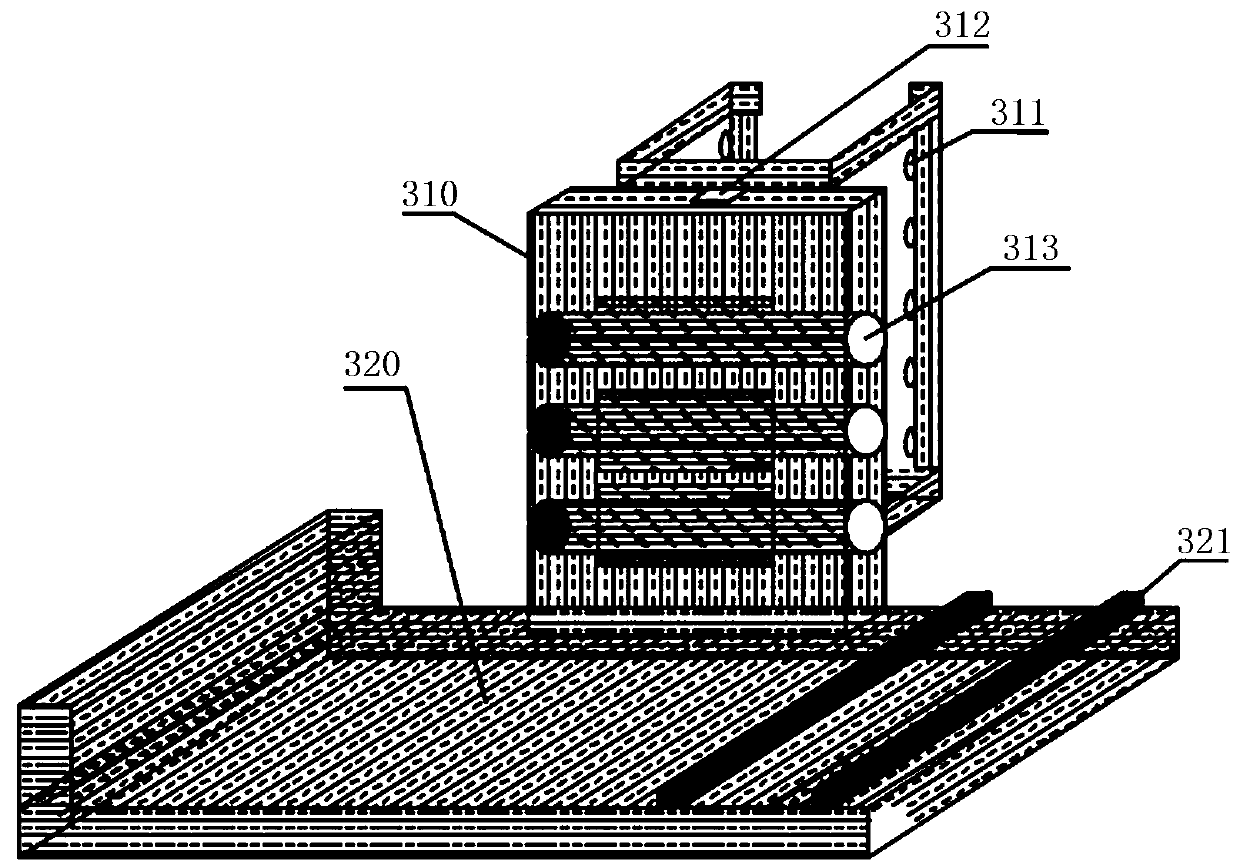

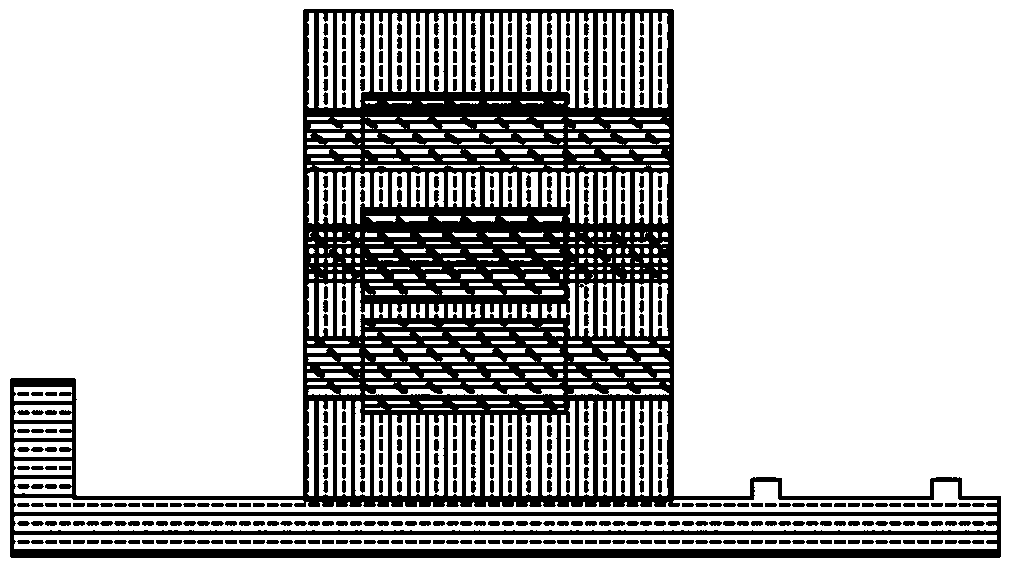

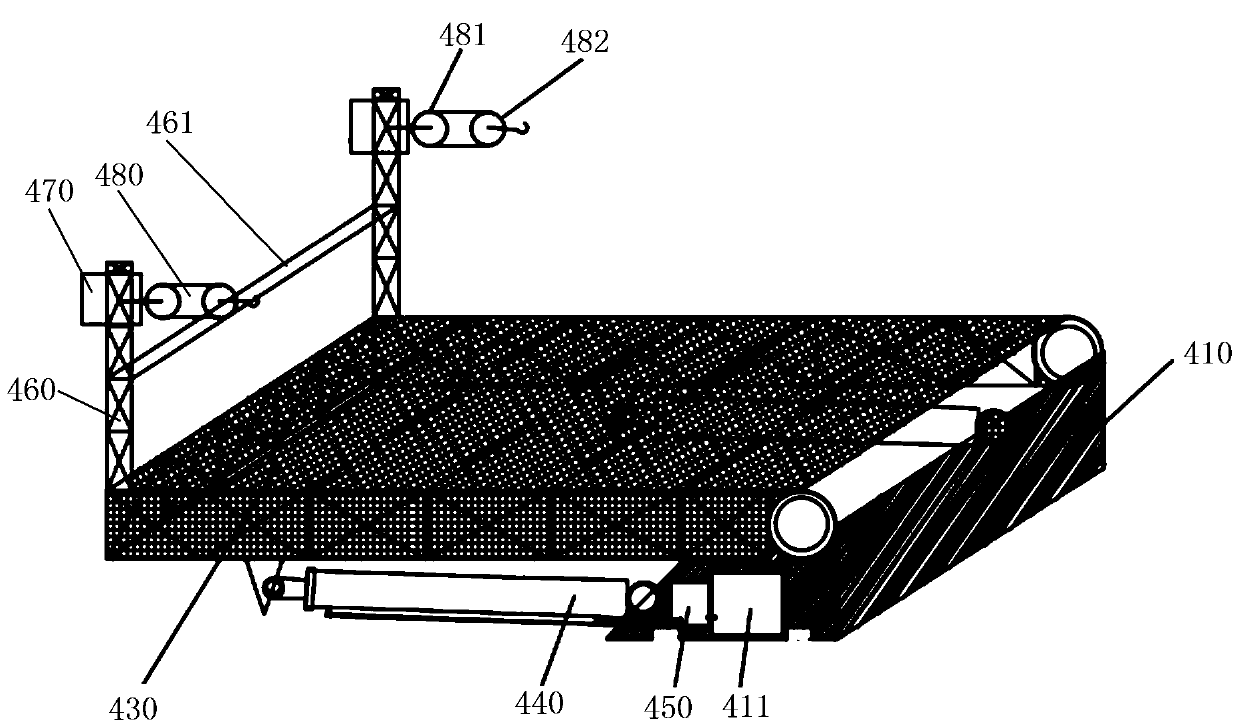

[0037] Such as Figure 8 As shown, the vertical steel frame 200 is built next to the prefabricated building 100, and the vertical transport device 300 is installed on the vertical steel frame 200. Such as figure 1 , 2 As shown, the vertical transport device 300 includes a vertical part 310 and a transport platform 320. The back of the vertical part 310 of the vertical transport device 300 is provided with a stabilizer 311 surrounding the vertical steel frame. The vertical part 310 communicates with the vertical The straight steel frame 200 is connected, specifically, the vertical rack 201 is set on the vertical steel frame 200, and a plurality of lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com